Frozen drink with pattern sprayed on surface and preparation method thereof

A technology for frozen drinks and surface spraying, which is applied in the fields of frozen desserts, food science, and applications. It can solve problems such as stagnation and clogging of discharge nozzle production, and achieve the effect of simple surface pattern, improved competitiveness, and broadened development ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0033] Preparation Example 1, Preparation of the Frozen Drink with Surface Spray Pattern

[0034] Batching → Homogenization → Sterilization → Cooling → Aging → Feed liquid is puffed by freezing machine → forming through discharge nozzle → cutting → inserting chopsticks → surface spray pattern → quick freezing → packaging → storage

Embodiment 1

[0035] Embodiment 1, the influence of powder spraying material on spraying effect

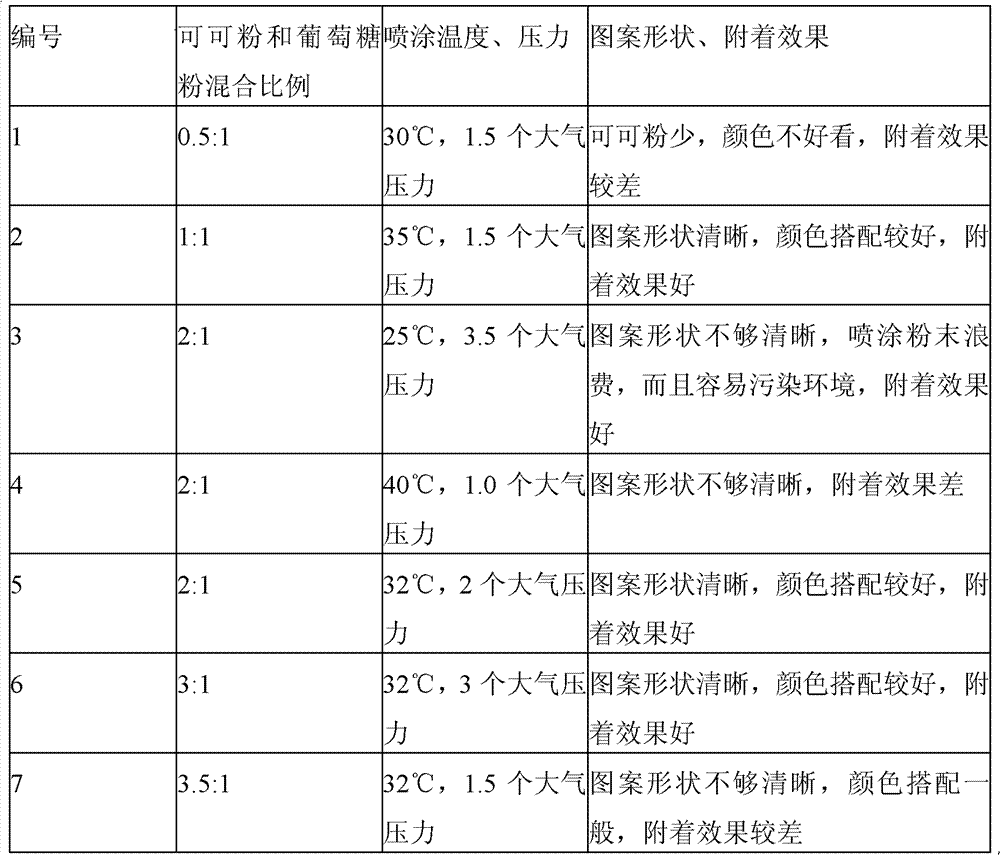

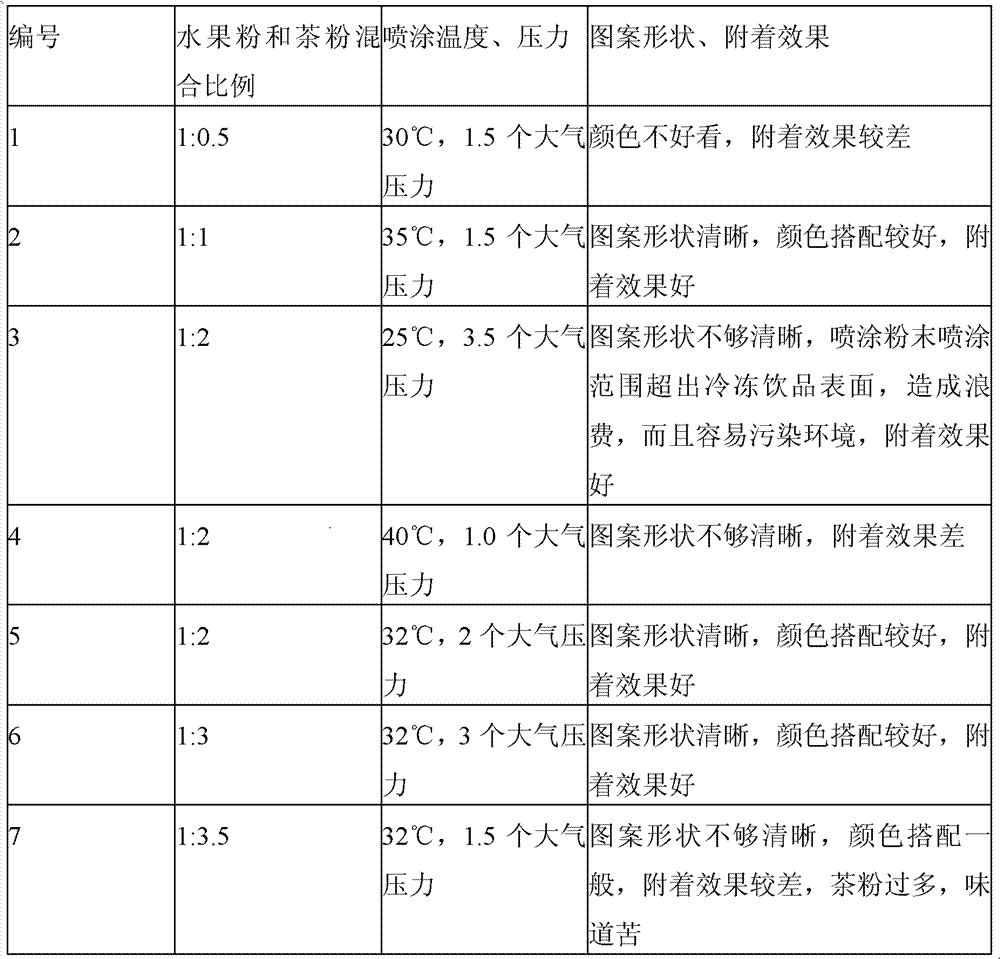

[0036] In the present invention, not all materials can be used for spraying frozen drinks. The present invention determines that the mixture of cocoa powder and glucose powder and the mixture of fruit powder and tea powder can be sprayed, and can be better attached to frozen drinks. However, the combination of spraying powders is not achievable by mixing in any proportion, and it must be combined with its spraying process to obtain good results. The inventors investigated this, and the results are shown in Table 1.

[0037] Table 1 The influence of different proportions of cocoa powder and glucose powder and spraying conditions on the spraying effect

[0038]

[0039] From the data in the above table, it can be seen that the spraying effect of glucose powder and cocoa powder is influenced by the ratio between the two and the three factors of spraying temperature and spraying pressure. First,...

Embodiment 2

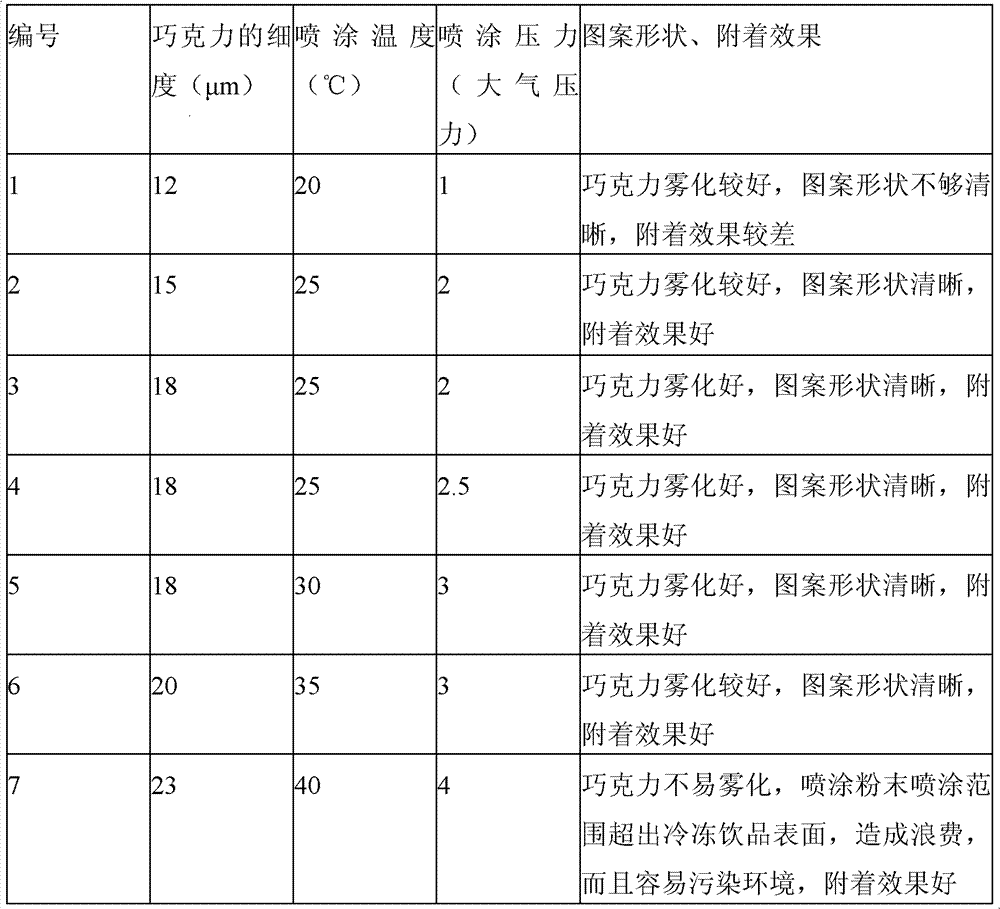

[0043] Embodiment 2, the influence of the fineness of chocolate, spraying temperature, pressure on spraying effect

[0044] In addition, the inventors investigated the effects of chocolate fineness, spraying temperature, and pressure on the spraying effect, and the results are shown in Table 3.

[0045] Table 3 Chocolate fineness, spraying temperature, pressure on the influence of spraying effect

[0046]

[0047] From the data in the above table, it can be seen that when chocolate is selected for spraying, its fineness, spraying temperature and pressure interact together to affect the spraying effect. The molding of the pattern; the fineness is too small, it is difficult to realize in the workshop, and the fine grinding of chocolate takes a long time to waste energy and increase the cost. Secondly, low spraying temperature and high viscosity of chocolate are not conducive to atomization, and also affect the formation of patterns. High temperature will cause the surface of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com