A kind of anti-mud type polycarboxylate water reducer and its preparation method and application in concrete

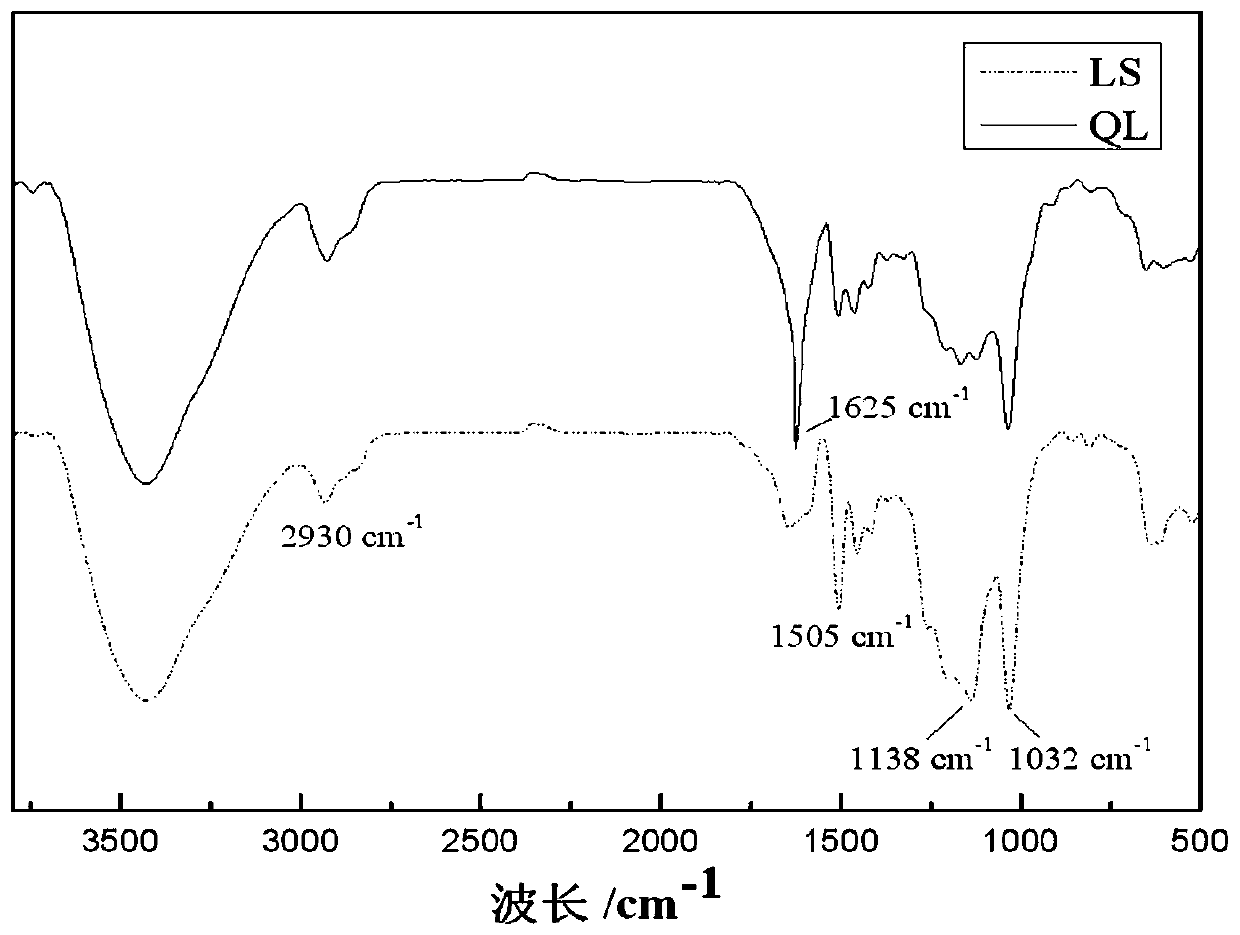

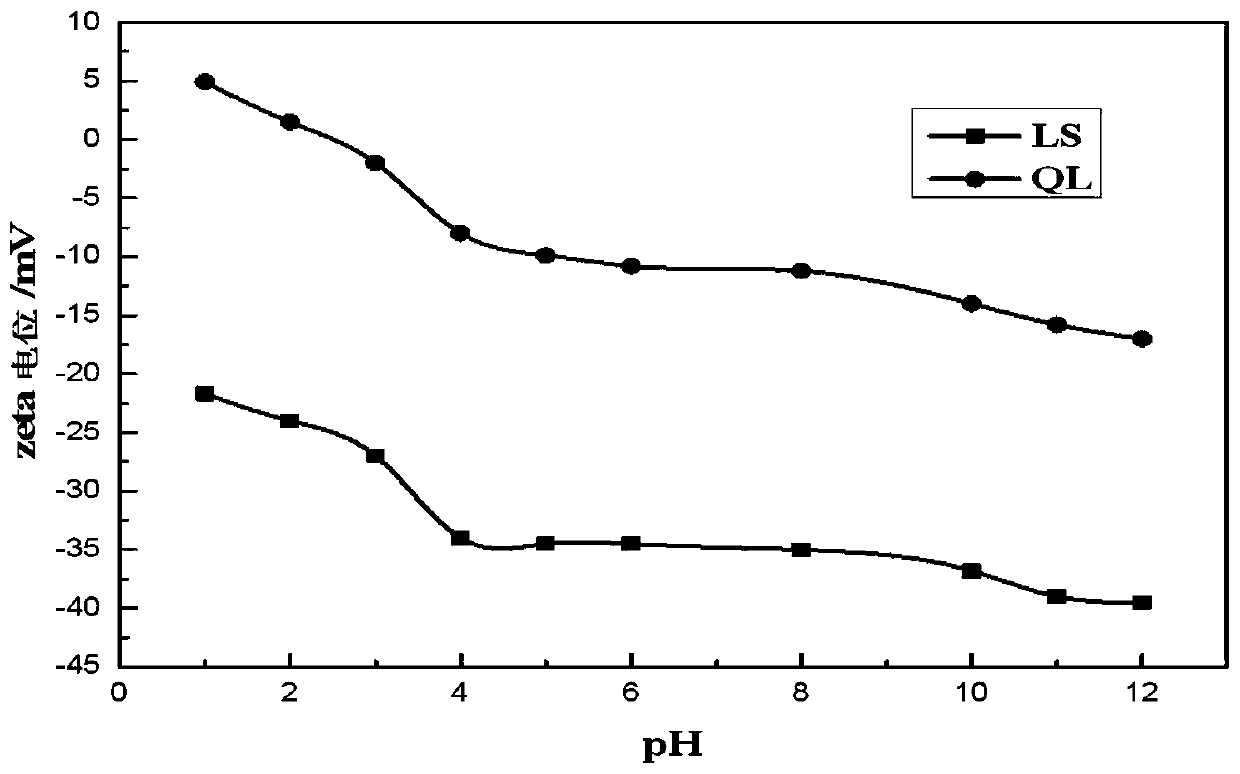

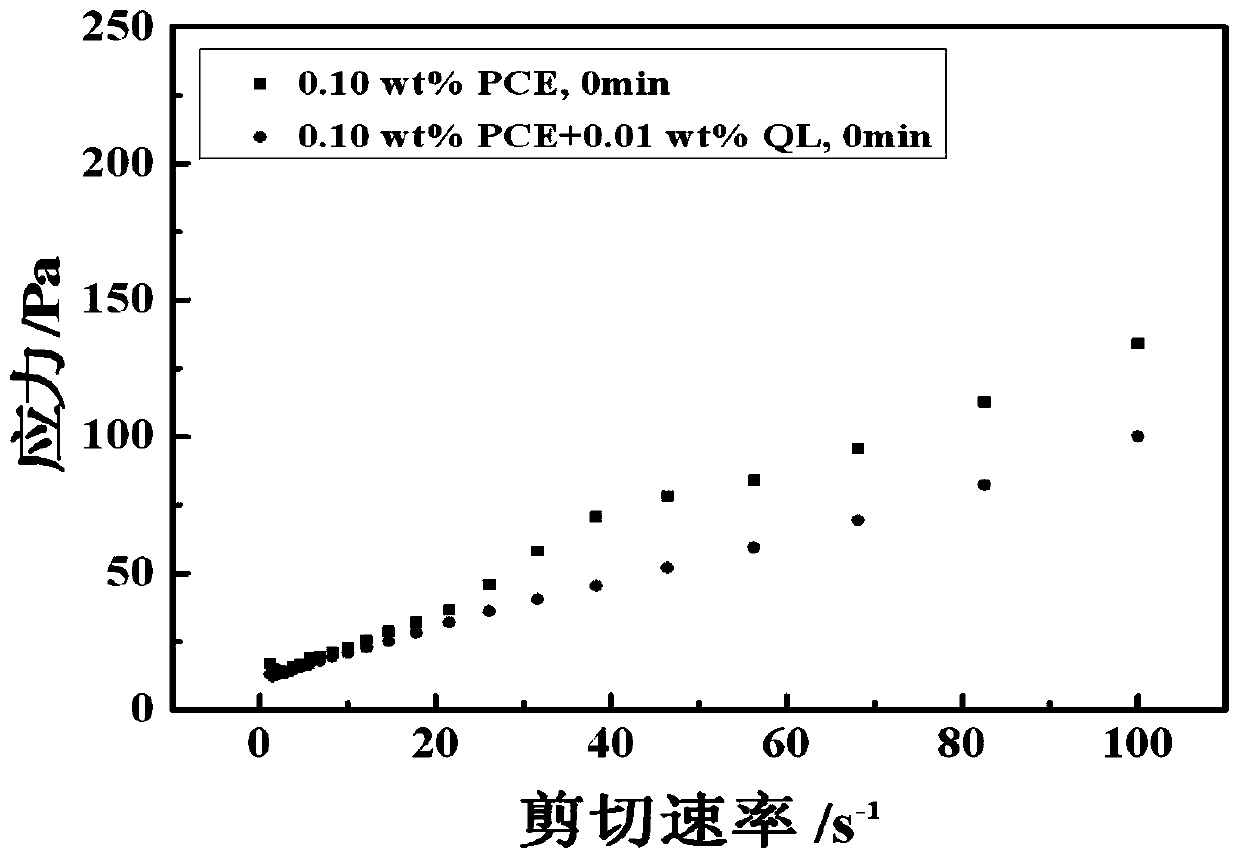

A technology of water reducer and polycarboxylate, which is applied in the anti-mud field of compound polycarboxylate water reducer, can solve the problems of wasting resources, polluting the environment, and poor dispersibility, and achieves improved fluidity, low cost, and disperse good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Dissolve 70g of wheatgrass sodium lignosulfonate in a beaker, add 280mL of deionized water, adjust the pH to 12 with sodium hydroxide, fully stir and dissolve for later use. The wheat straw sodium lignosulfonate solution was poured into a four-neck flask, mechanically stirred and heated to 80° C. in a water bath, and the stirring speed was 200 r / min.

[0050] (2) Add 28.01g of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC) into 15.09g of water as a solvent, and then add 3-chloro-2-hydroxypropyltrimethylammonium dropwise to the above-mentioned four-necked flask using a peristaltic pump. Methyl ammonium chloride solution, stirring continuously. Add 14.9 g of 20% NaOH solution and continue heating to 85°C.

[0051] (3) After the addition of the 3-chloro-2-hydroxypropyltrimethylammonium chloride solution is completed, the product can be obtained after the reaction at 85° C. for 4 hours.

[0052] The application test of the quaternized lignosulfonate anti-...

Embodiment 2

[0068] (1) Dissolve 70g of bamboo pulp sodium lignosulfonate in a beaker, add 280mL of deionized water, adjust the pH to 12 with sodium hydroxide, fully stir and dissolve for later use. Pour the sodium lignosulfonate solution of bamboo pulp into a four-necked flask, stir it mechanically and heat it in a water bath to 80°C, and the stirring speed is 200r / min.

[0069] (2) Add 28.01g of 2,4-bis(dimethylamino)-6-chloro-[1,3,5]-triazine (BDAT) into 15.09g of water, and then use a peristaltic pump to drop , continue to stir evenly, add 14.9g of 20% NaOH solution, and continue heating to 85°C.

[0070] (3) After the 2,4-bis(dimethylamino)-6-chloro-[1,3,5]-triazine solution in step (2) was added, the product was obtained after a reaction at 85° C. for 4 hours.

Embodiment 3

[0072](1) Dissolve 70g of wood pulp sodium lignosulfonate in a beaker, add 280mL of deionized water, adjust the pH to 12 with sodium hydroxide, fully stir and dissolve for later use. Pour the wood pulp sodium lignosulfonate solution into a four-necked flask, stir it mechanically and heat it in a water bath to 80°C, and the stirring speed is 200r / min.

[0073] (2) Add 28.01g propylene oxide-trimethyl-ammonium salt (OMTMA) into 15.09g water, then use a peristaltic pump to drip the propylene oxide-trimethyl-ammonium salt solution to the above-mentioned four-necked flask, and continue Stir evenly, add 14.9g of 20% NaOH solution, and continue heating to 85°C.

[0074] (3) After adding the epoxypropylene-trimethyl-ammonium salt (OMTMA) solution in the step (2), the product was obtained after the reaction at 85° C. for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com