A method of detonation spraying based on explosive detonation

A technology of explosive spraying and explosive action, which is applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of limited coating area, no explosive spraying, high production cost, and achieve good and uniform spraying effect. Surface finish, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

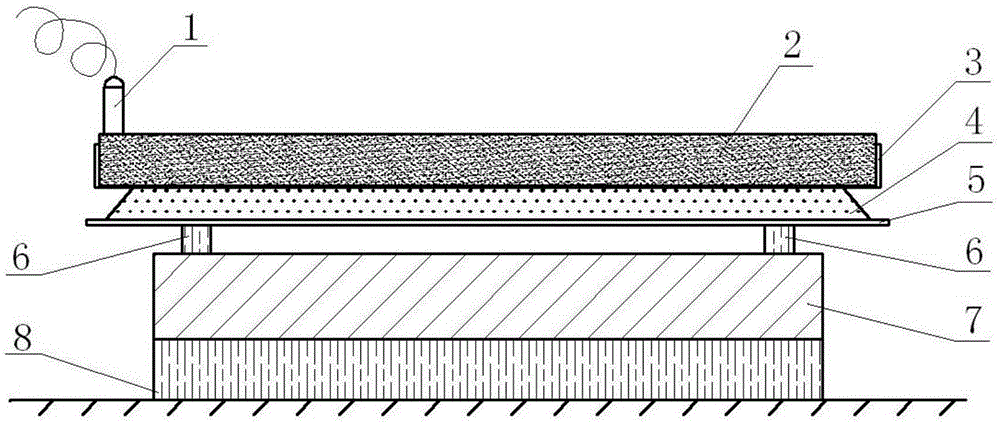

[0019] The invention uses explosives as an energy source, and utilizes the shock wave generated by the explosion of the explosives to drive the metal powder to spray on the surface of the metal substrate. The present invention comprises the following components for realizing detonation spraying: detonation mechanism 1, flake charge 2, charge box 3, metal powder 4 for spraying, thin paper sheet 5, support pad 6, metal substrate 7 and wooden backing plate 8 .

[0020] The specific steps of the present invention are as follows: a. place the wooden backing plate horizontally, place the metal substrate on it, and place a support pad on the surface of the metal substrate; b. place the thin paper sheet on the support pad, calculate and weigh according to the coating thickness requirements Spread the metal powder for spraying evenly on the surface of the thin paper sheet; c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com