Organic-solvent-soluble polyimide comprising PMDA, DADE, BPDA, and BCD

A technology of polyimide and organic solvent, applied in the field of bicyclooctene tetracarboxylic dianhydride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

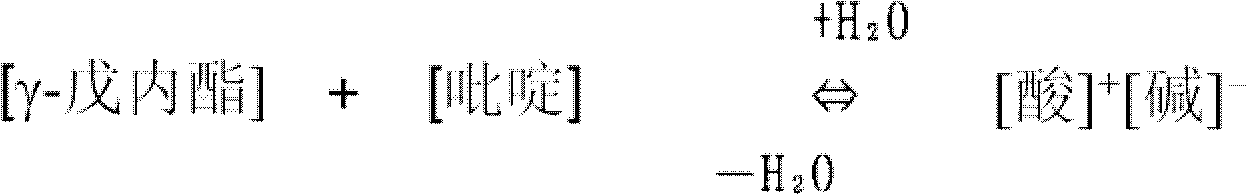

Problems solved by technology

Method used

Image

Examples

corresponding Embodiment 1

[0090] Corresponding to the manufacturing method of embodiment 1

[0091] Contains the following three stages:

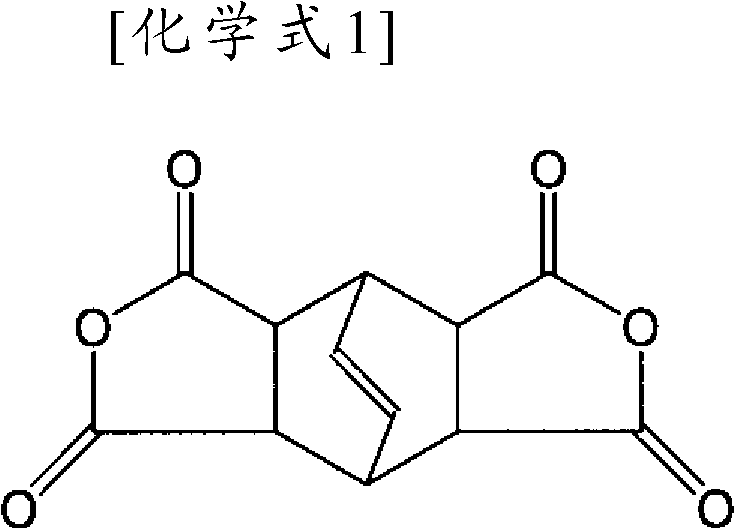

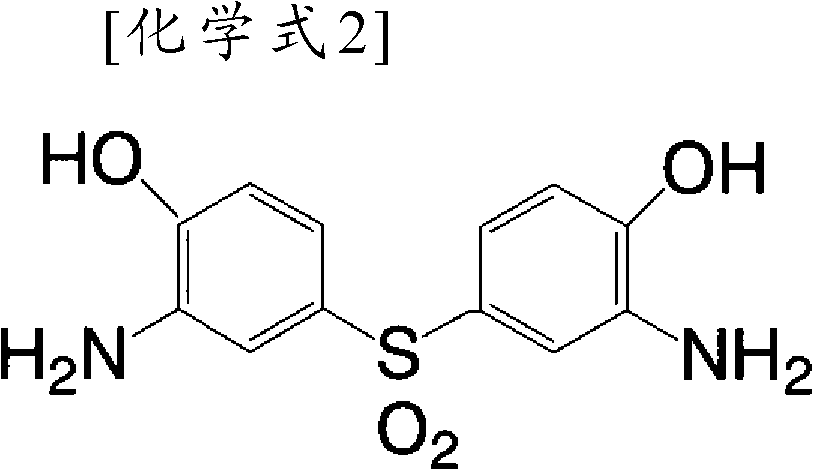

[0092] (a) In the first stage, 2 molar equivalents of pyromellitic dianhydride (PMDA) and bis(3-amino-4-hydroxyphenyl)sulfone (HOAB·SO 2 ) 1 molar equivalent reacts at 160~200 DEG C in the presence of a catalyst in a polar organic solvent to generate an oligomer whose two ends are PMDA,

[0093] (b) In the second stage, the oligomer generated in the first stage reacts with 2 molar equivalents of bicyclooctene tetracarboxylic dianhydride (BCD) and 4 molar equivalents of 3,4'-diaminodiphenyl ether (mDADE) , generating oligomers with mDADE at both ends, and

[0094] (c) In the third stage, add 2 molar equivalents of biphenyltetracarboxylic dianhydride (BPDA) and 1 molar equivalent of 1,3-bis(4-aminophenoxy)benzene (mTPE), react, polycondensate, and synthesize Polyimide copolymer soluble in polar organic solvents.

corresponding Embodiment 2

[0095] Corresponding to the manufacturing method of embodiment 2

[0096] Contains the following three stages:

[0097] (a) In the first stage, 2 molar equivalents of pyromellitic dianhydride (PMDA) and bis(3-amino-4-hydroxyphenyl)sulfone (HOAB·SO 2 ) 1 molar equivalent reacts at 160~200 DEG C in the presence of a catalyst in a polar organic solvent to generate an oligomer whose two ends are PMDA,

[0098] (b) In the second stage, the oligomer generated in the first stage reacts with 2 molar equivalents of bicyclooctene tetracarboxylic dianhydride (BCD) and 4 molar equivalents of 3,4'-diaminodiphenyl ether (mDADE) , generating oligomers with mDADE at both ends, and

[0099] (c) In the third stage, add 2 molar equivalents of benzophenone tetracarboxylic dianhydride (BTDA) and 1 molar equivalent of 1,3-bis(4-aminophenoxy)benzene (mTPE), react and polycondense, Synthesis of polyimide copolymers soluble in polar organic solvents.

[0100] In the reaction of embodiment 1 and ...

Embodiment 1

[0106] The composition ratio of embodiment 1 is (PMDA) 2 (mDADE) 4 (BCD) 2 (HOAB SO 2 ) 1 (mTPE) 1 (BPDA) 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com