Ball end mill

A technology of ball end mills and end mills, which is applied in the direction of milling cutters, forming cutters, milling machine equipment, etc., can solve the problem of chip clogging, achieve the effect of suppressing the increase of resistance and load, and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

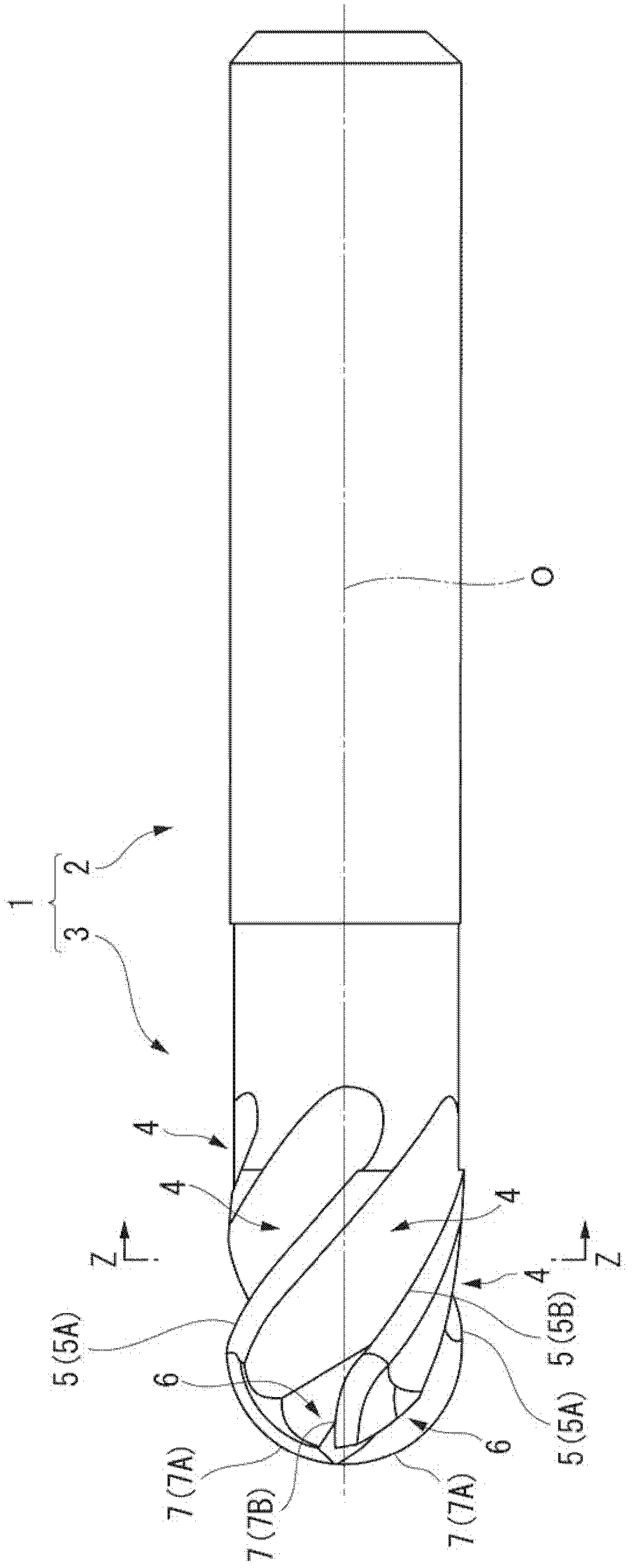

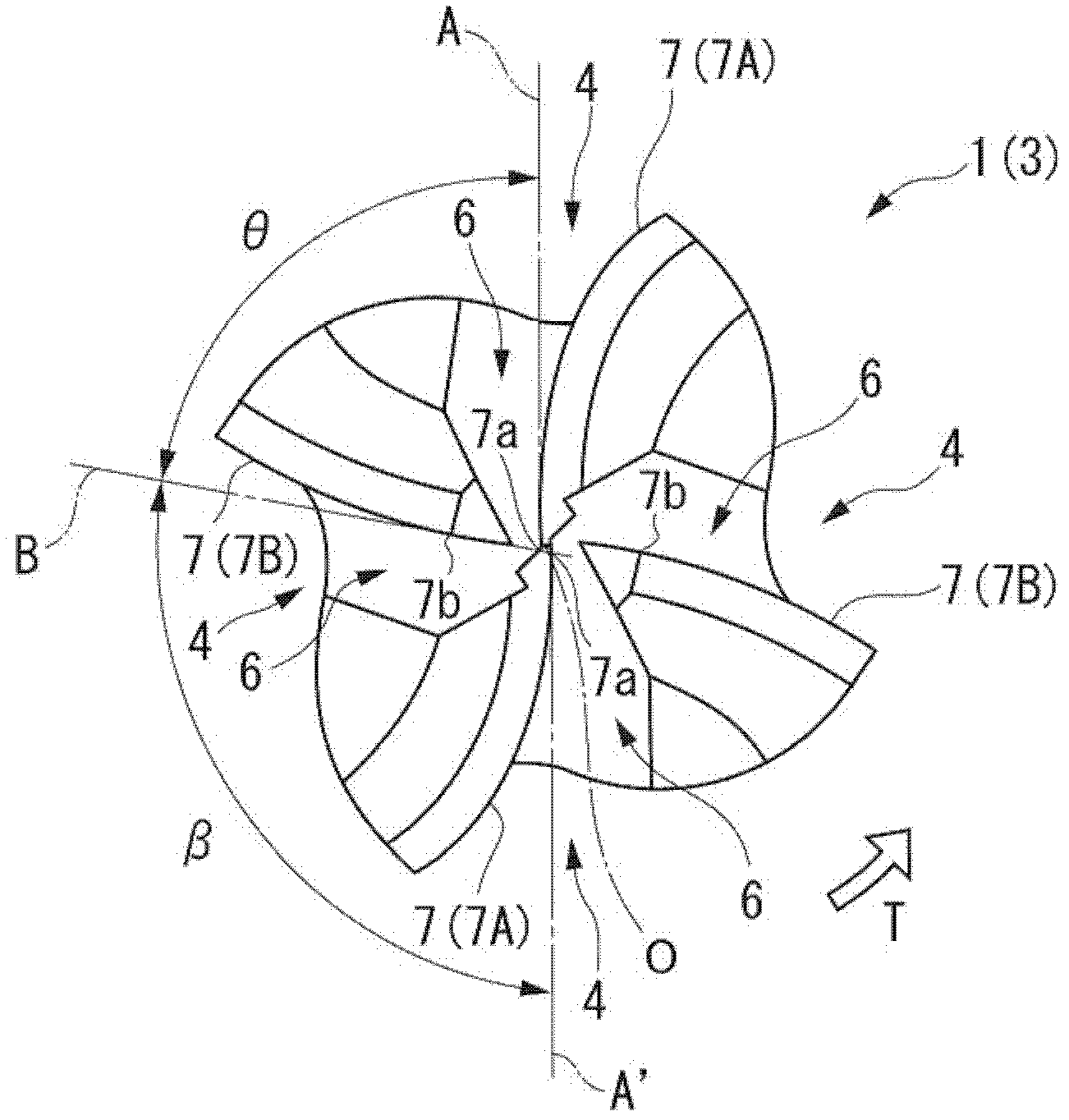

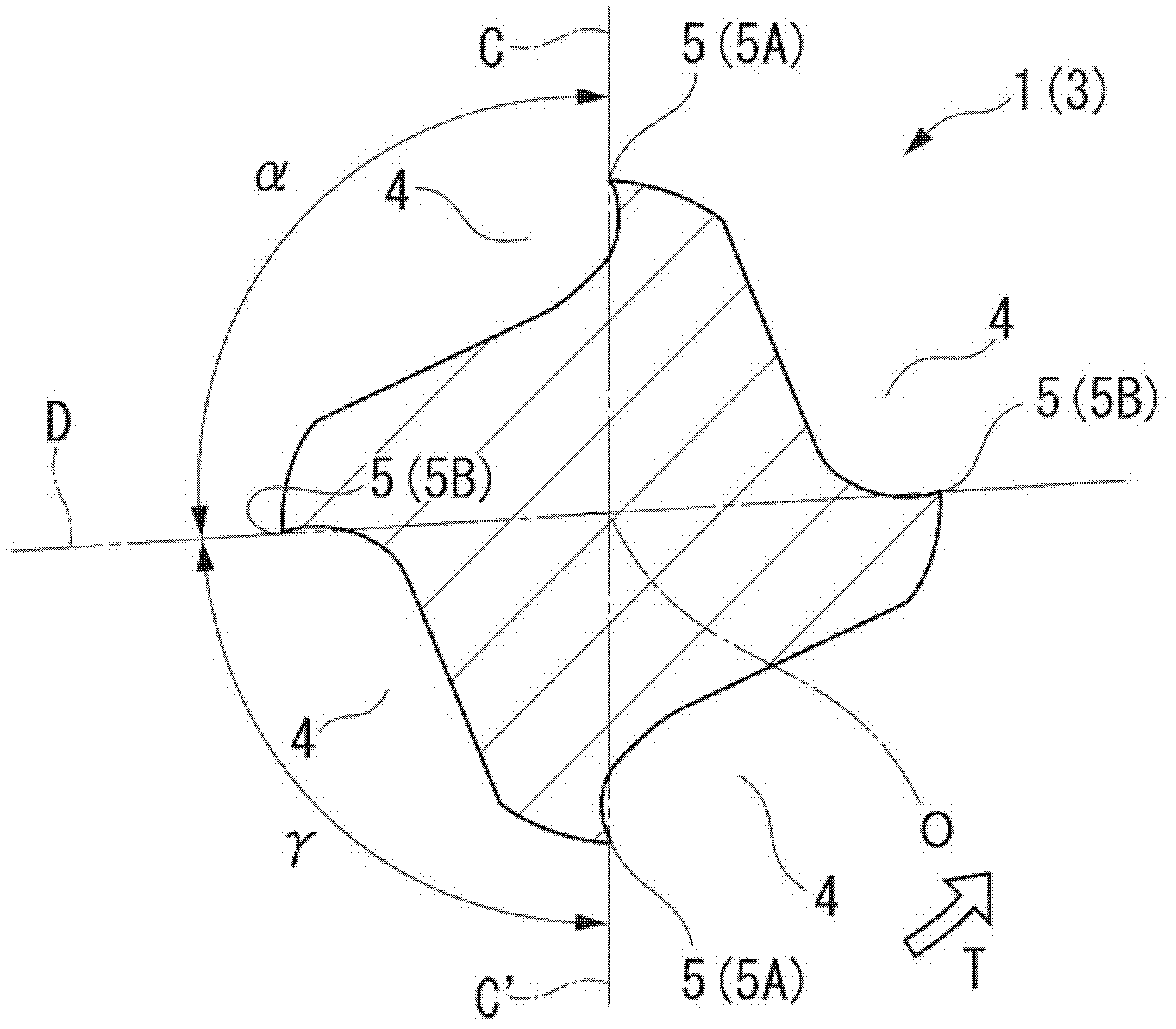

[0021] exist figure 1 , Figure 2A with Figure 2B In the illustrated embodiment of the present invention, the end mill body 1 is formed in a substantially cylindrical shape centered on the axis O. As shown in FIG. At the rear end of the end mill body 1 ( figure 1 The right side in the middle) is formed with a shank portion 2, and a cutting edge portion 3 is formed at the front end. The end mill body 1 is fed in a direction intersecting the axis O while being rotated in the rotation direction T around the axis O by mounting the shank portion 2 to the spindle of the machine tool, and is cut by the cutting edge portion 3 The material is cut. In addition, depending on the situation, while feeding in a direction intersecting the axis O, it also feeds in a direction along the axis O from the rear end of the end mill body 1 toward the front end, thereby also cutting the workpiece.

[0022] On the outer periphery of the cutting edge portion 3, a plurality of (four in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com