Shear force connection member for flexible welding nails of combined structure of steel and concrete

A technology of combining structures and connecting components, applied in bridge parts, building structures, buildings, etc., can solve the problems of weak shear strength of joint surfaces, large tensile stress of concrete, self-fatigue damage, etc. The effect of improving force performance and increasing pre-energizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

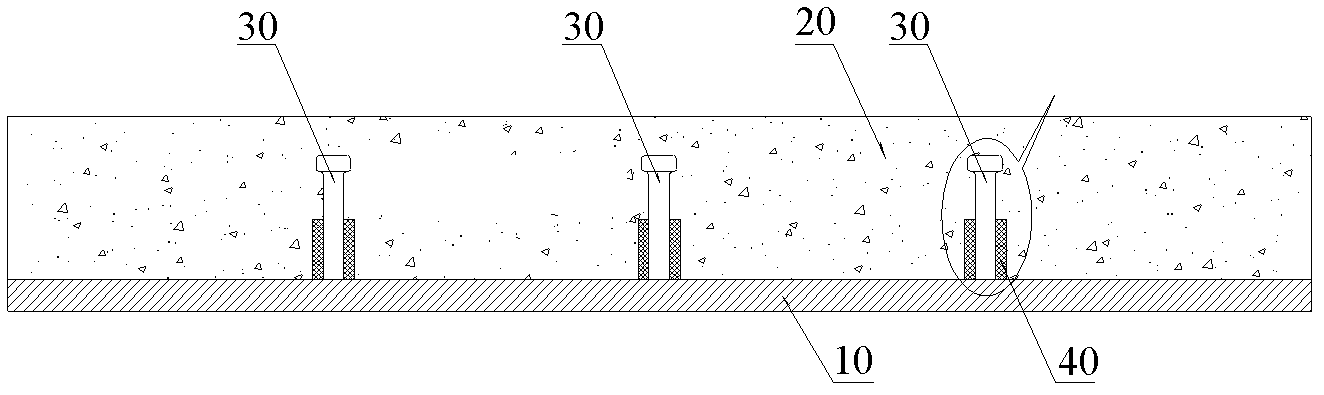

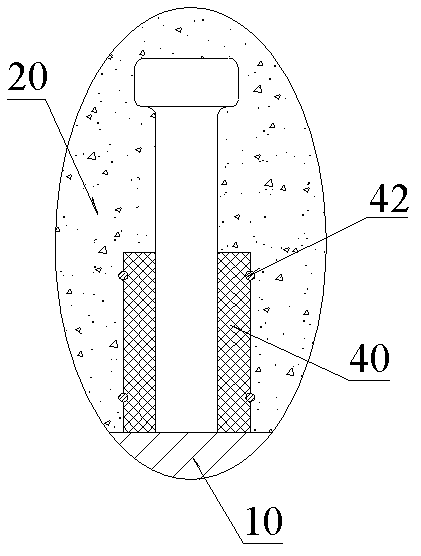

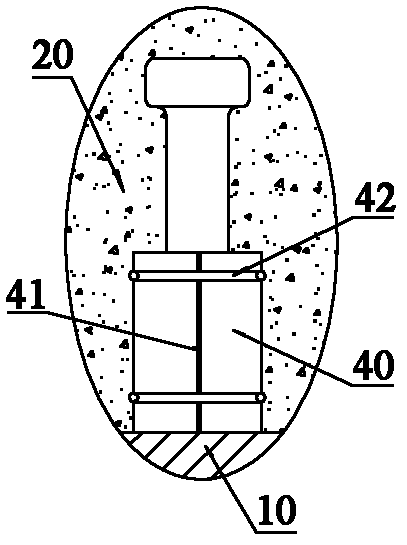

[0014] refer to figure 1 , a flexible welding stud shear connection member for steel and concrete composite structures, including a steel member 10, a concrete member 20, and a welding stud 30 welded and fixed on the steel member structure 10 and embedded in the concrete member 20, the A flexible rubber sheath 40 is provided over the root of the welding stud 30 . During construction, the welding stud 30 is welded on the steel member, and then the flexible rubber sleeve 40 is installed at the root of the welding stud 30, and then the concrete member 20 is poured on the steel member 10. After the concrete member 20 reaches the design strength, the shear force can be passed. Connectors transmit internal forces between steel and concrete members. Compared with welding studs of the same specification but without flexible rubber sleeves, this connector has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com