Technique of finishing laterally-hydrophilic and laterally-waterproof clothing fabrics

A technology of waterproof finishing and hydrophilic finishing, applied in dyeing method, textile and papermaking, plant fiber and other directions, can solve the problems of heavy weight and poor air permeability of single-parent single-proof fabric, and achieve the effect of small weight impact and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] White 30D in the present embodiment, the 100% polyester woven fabric production of 300t is as follows:

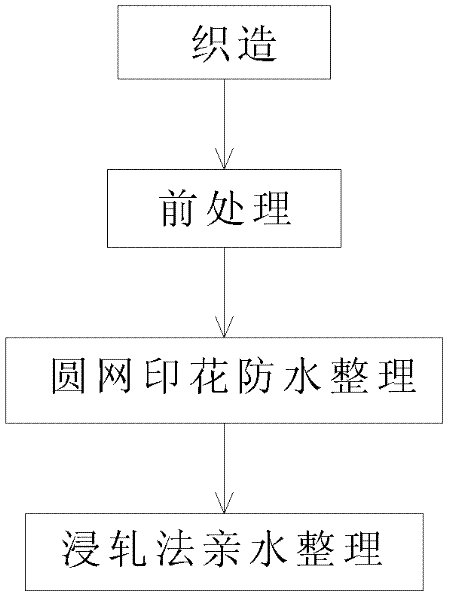

[0057] White 30D, 300t double-sided superpower single parent single anti-polyester fabric production process:

[0058] Gray cloth→refining→dyeing→soaping→drying→printing→baking→washing→drying→padding hydrophilic additives→drying→baking→washing→drying

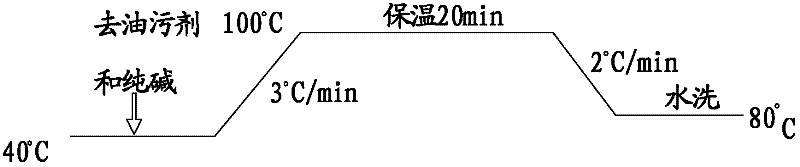

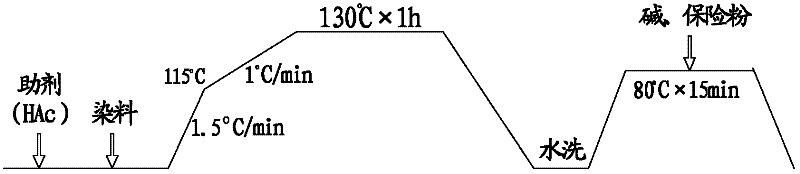

[0059] 1) Scouring, dyeing, soaping, and drying follow the conventional process of the workshop; the scouring requirements are sufficient to prevent oil stains and other impurities on the cloth surface from affecting subsequent processing.

[0060]2) Preparation of printing paste: Stir 145g / kg of fluorocarbon resin, 15g / kg of crosslinking agent and 800g / kg of fluorocarbon thickener (1%) with a three-bladed agitator under the condition of 1200r / min for 17min to obtain A slurry with a viscosity of 7500 mps. The resulting slurry was applied to the face side of the fabric by a rotary screen printing machine at a speed of...

Embodiment 2

[0068] Blue 40D in the present embodiment, the 100% polyester woven fabric production of 400t is as follows:

[0069] Production process of blue 40D, 400t double-sided single parent single anti-polyester fabric:

[0070] Gray cloth→refining→dyeing→soaping→drying→printing→baking→washing→drying→padding hydrophilic additives→drying→baking→washing→drying

[0071] 1) Scouring, dyeing, soaping, and drying follow the conventional process of the workshop; the scouring requirements are sufficient to prevent oil stains and other impurities on the cloth surface from affecting subsequent processing.

[0072] 2) Preparation of printing paste: Stir 130g / kg of fluorocarbon resin, 10g / kg of crosslinking agent and 800g / kg of fluorocarbon thickener (1%) with a three-blade stirrer for 15min under the condition of 1200r / min to obtain A slurry with a viscosity of 7000 mps. The resulting slurry was applied to the front side of the fabric by a rotary screen printing machine at a speed of 50 m / min....

Embodiment 3

[0080] In this example, 40S has a density of 200-250g / m 2 The production of polyester-cotton blended (80% polyester, 20% cotton) single-parent single-proof fabric is as follows:

[0081] Gray cloth→refining→dyeing→soaping→drying→printing→baking→washing→drying→padding hydrophilic additives→drying→baking→washing→drying

[0082] 1) Scouring, dyeing, soaping, and drying follow the conventional process of the workshop; the scouring requirements are sufficient to prevent oil stains and other impurities on the cloth surface from affecting subsequent processing.

[0083] 2) Preparation of printing paste: 160g / kg of fluorocarbon resin, 15g / kg of crosslinking agent and 840g / kg of fluorocarbon thickener (1%) were stirred for 15min with a three-blade agitator under the condition of 1200r / min to obtain A slurry with a viscosity of 10000 mps. The resulting slurry was applied to the face side of the fabric by a rotary screen printing machine at a speed of 45 m / min. Then dry and bake on an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com