Production method of tight sirospun yarn of combed crystal cotton

A technology of siro spinning and production methods, which is applied to spinning machines, continuously wound spinning machines, yarns, etc., can solve the problems of low breaking strength, performance degradation, and fibers are easily broken and brittle, and achieve breaking strength Effects of increased, decreased hairiness, high hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

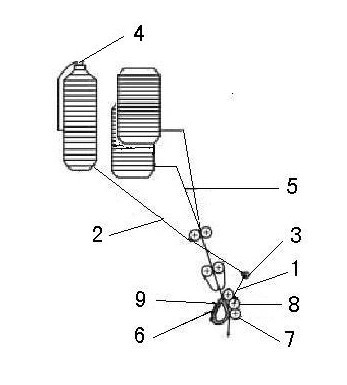

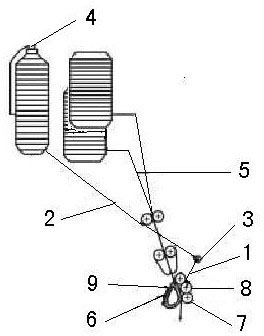

Image

Examples

Embodiment Construction

[0020] The production method of crystal cotton combed cotton compact siro spinning includes the following processes in sequence: 1), combed cotton preparation → 2), combed cotton and crystal cotton cleaning and mixing → 3), carding → 4), Draw frame (two passes) → 5), roving → 6), compact siro spun yarn mixed with nylon filament → 7), winding. Related equipment process: A002D type plucking machine, A035 type opening and mixing machine, FA025 multi-storey cotton mixing machine, FA106 type cotton opening machine, FA161 type vibrating cotton feeding machine, A076F type single beater lapping machine - FA224 type carding Machine one FA311F drawing frame*2 one FA458 roving frame one FA506 spinning frame one NO.21C Murata automatic winder.

[0021] 1. Combed cotton preparation process: Due to many reasons such as high impurity content of raw cotton and poor fiber straightness, the pretreatment method of combing is adopted. The process flow is as follows: A002D type plucking machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com