Low-roughness silicon wafer alkali corrosion process

A low-roughness, alkali-etching technology, applied in the field of low-roughness silicon wafer alkali-etching process, can solve problems such as the adverse effects of subsequent polishing and poor surface roughness of alkali-corrosion wafers, meet the requirements, speed up the corrosion rate, and improve the The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

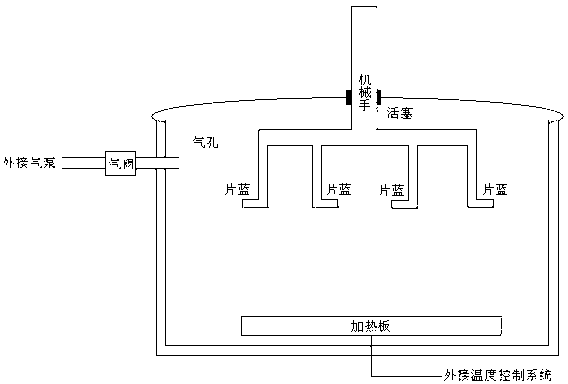

Image

Examples

Embodiment 1

[0018] Embodiment 1: The following is a detailed description of the alkali corrosion process of a 5-inch 375 μm thick zone-melted silicon double-sided ground silicon wafer:

[0019] 1) Select a 5-inch P-doped zone-melted silicon abrasive sheet with a thickness of 375 μm as the object of implementation, with a resistivity of 10-30Ω·cm.

[0020] 2) Use solid KOH (analytical pure) and deionized water to prepare a 47.3% KOH aqueous solution in a high-pressure water bath.

[0021] 3) Set the preparation temperature to 120°C, turn on the heater switch, and raise the temperature to the preparation temperature.

[0022] 4) Load the slices with abrasive slices into the manipulator of the high-pressure water bath, load 2 baskets of 50 slices at a time, and close the upper cover of the high-pressure water bath.

[0023] 5) Pressurize to 240Kpa; heat up to 153°C.

[0024] 6) The sinking manipulator dips the ingot into the corrosive solution, performs alkali corrosion for 3 minutes and 2...

Embodiment 2

[0039] Embodiment 2: The following is a detailed description of the alkali corrosion process of a 4-inch 410 μm thick zone-melted silicon double-sided ground silicon wafer:

[0040] 1) Select a 4-inch P-doped zone-fused silicon abrasive sheet with a thickness of 410 μm as the object of implementation, with a resistivity of 5-10Ω·cm.

[0041] 2) Use solid NaOH (analytical pure) and deionized water to prepare a 49.5% KOH aqueous solution in a high-pressure water bath.

[0042] 3) Set the preparation temperature to 120°C, turn on the heater switch, and raise the temperature to the preparation temperature.

[0043] 4) Load the flakes with abrasive flakes into the manipulator of the high-pressure water bath, load 2 baskets of 50 flakes at a time, and close the upper cover of the water bath.

[0044] 5) Pressurize to 250Kpa; heat up to 157°C.

[0045] 6) The sinking manipulator dips the ingot into the corrosive solution, carries out alkali corrosion for 2 minutes and 54 seconds, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com