Nanometer carboxylated polystyrene microsphere with spacer arm and preparation method thereof

A technology of polystyrene microspheres and spacer arms, which is applied in the field of nano-scale carboxylated polystyrene microspheres and its preparation, can solve the problems of steric hindrance, influence the coupling rate and biological activity of biological macromolecules, etc. Steric hindrance, simple and economical equipment, improved coupling rate and utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

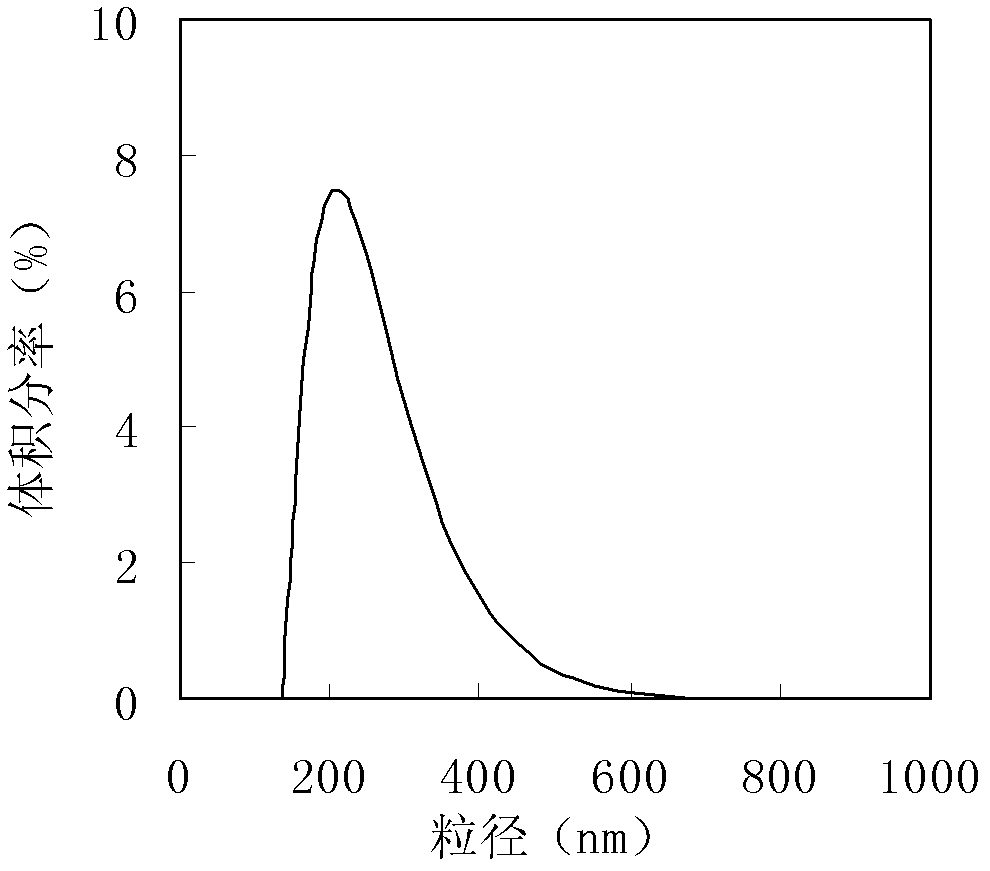

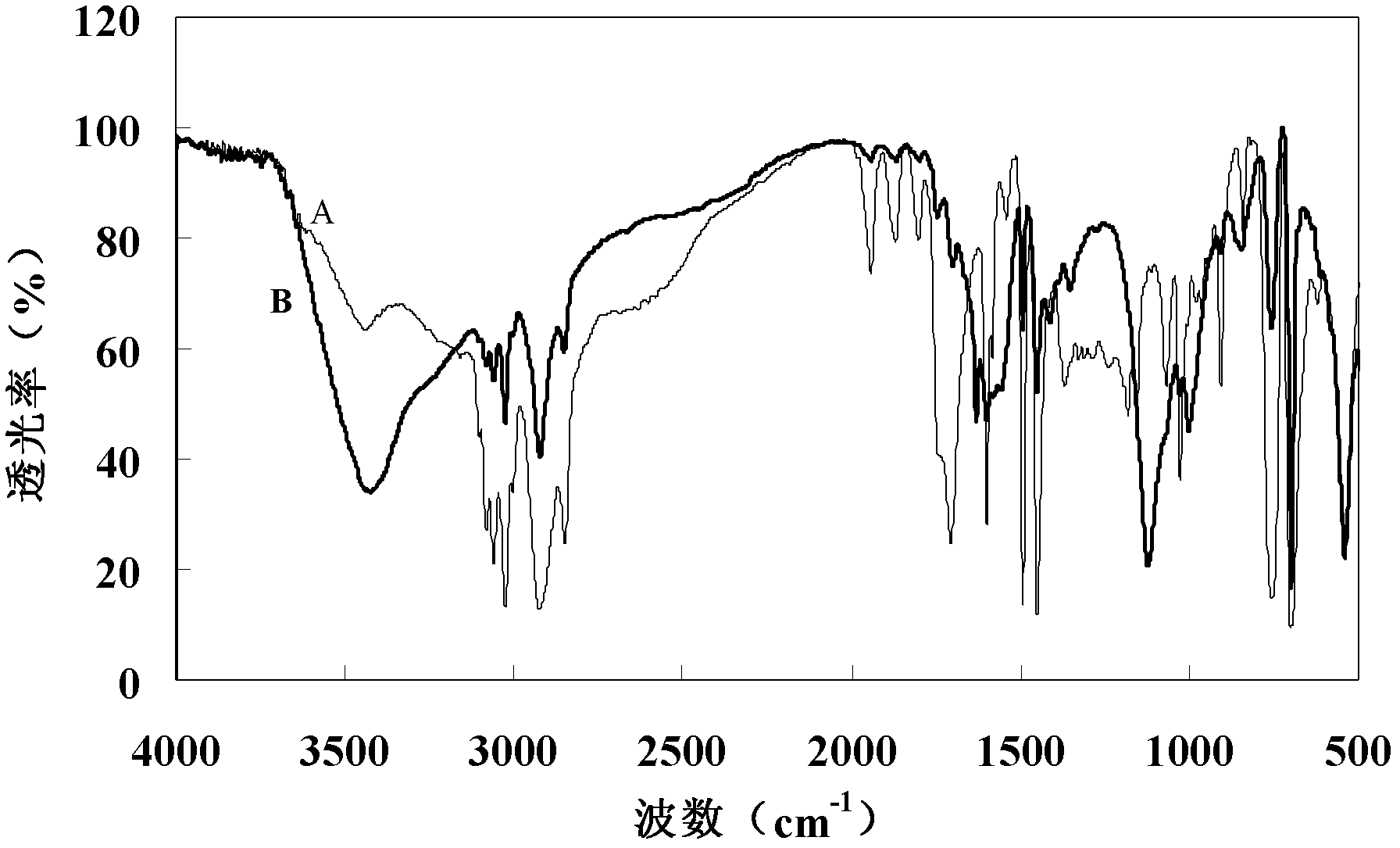

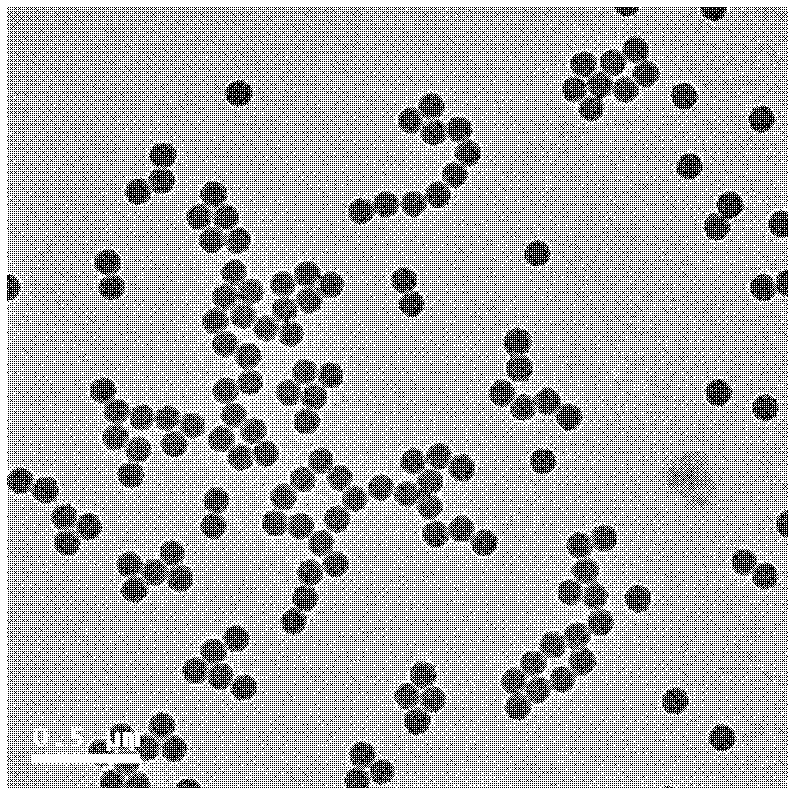

[0027]Wash styrene four times with 5% NaOH solution, then wash styrene with distilled water until neutral, separate the water layer, add anhydrous calcium chloride and dry overnight. The dried styrene was distilled under reduced pressure and stored in a refrigerator at 4°C. Preparation concentration is the potassium persulfate (KPS) aqueous solution of 0.05%, pipettes the potassium persulfate solution of 40ml and joins in the Erlenmeyer flask of 250ml, adds 0.0024g (0.006%) sodium dodecylsulfonate (SDS), waits for SDS After completely dissolving, add 4ml of mixed monomers of styrene and acrylic acid (the mass ratio of mixed monomers to water phase is 1:9), wherein 3.6ml of styrene and 0.4ml of acrylic acid. Nitrogen was passed through for 10 minutes to remove oxygen, and then emulsified on a shaker for 30 minutes. The flask was placed in a constant temperature water bath shaker at 60° C., and reacted for 10 h at a speed of 200 rpm to prepare carboxylated polystyrene microsphe...

Embodiment 2

[0030] Wash styrene four times with 5% NaOH solution, then wash styrene with distilled water until neutral, separate the water layer, add anhydrous calcium chloride and dry overnight. The dried styrene was distilled under reduced pressure and stored in a refrigerator at 4°C. Preparation concentration is the potassium persulfate (KPS) aqueous solution of 0.1%, pipettes the potassium persulfate solution of 40ml and joins in the Erlenmeyer flask of 250ml, adds 0.016g (0.04%) sodium dodecylsulfonate (SDS), waits for SDS After completely dissolving, add 4ml of mixed monomers of styrene and acrylic acid (the mass ratio of mixed monomers and water phase is 1:9), wherein 3.8ml of styrene and 0.2ml of acrylic acid. Nitrogen was passed through for 10 minutes to remove oxygen, and then emulsified on a shaker for 30 minutes. The flask was placed in a constant temperature water bath shaker at 70°C, and reacted for 16 hours at a speed of 200 rpm to prepare carboxylated polystyrene microsph...

Embodiment 3

[0033] Wash styrene four times with 5% NaOH solution, then wash styrene with distilled water until neutral, separate the water layer, add anhydrous calcium chloride and dry overnight. The dried styrene was distilled under reduced pressure and stored in a refrigerator at 4°C. Preparation concentration is the potassium persulfate (KPS) aqueous solution of 0.3%, pipettes the potassium persulfate solution of 40ml and joins in the Erlenmeyer flask of 250ml, adds 0.08g (0.2%) sodium dodecylsulfonate (SDS), waits for SDS After completely dissolving, add 4ml of mixed monomers of styrene and acrylic acid in total (the mass ratio of mixed monomers and water phase is 1:9), wherein styrene is 3.98ml, and acrylic acid is 0.02ml. Nitrogen was passed through for 10 minutes to remove oxygen, and then emulsified on a shaker for 30 minutes. The flask was placed in a constant temperature water bath shaker at 80°C, and reacted at a speed of 200 rpm for 24 hours to prepare carboxylated polystyren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com