Sharp-nose pliers

A technology of needle-nose pliers and pliers, applied in the field of needle-nose pliers, which can solve the problems of easy closing, reduced work efficiency, and difficulty in opening of long-nose pliers, and achieve the effects of reducing slipping, improving work efficiency, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

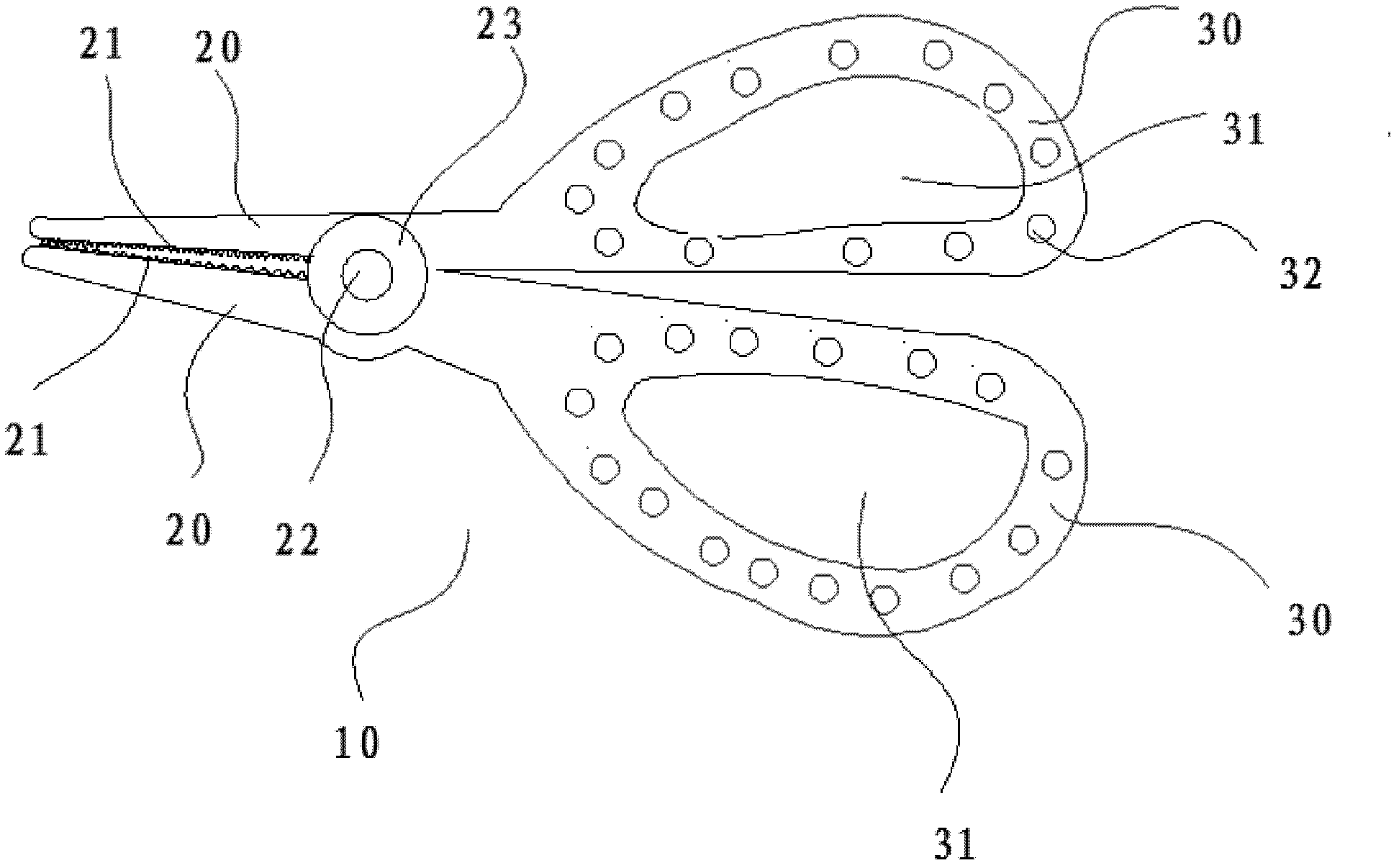

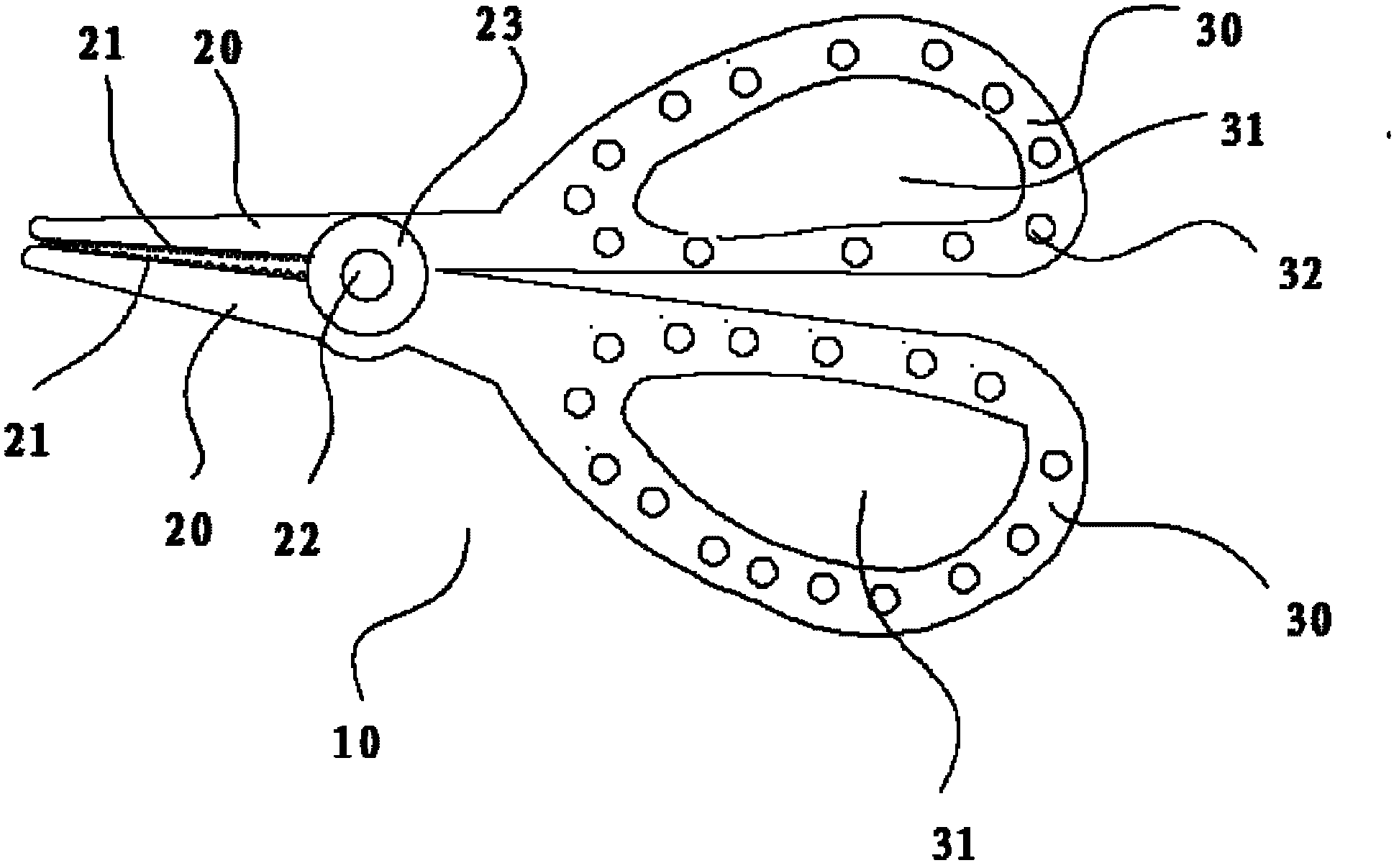

[0016] see figure 1 As shown, a needle-nose pliers 10 of the present invention includes a pliers body 20 and a pliers handle 30. The pliers body 20 and pliers handle 20 are integrally formed of stainless steel structure with simple processing technology, high hardness and strong corrosion resistance.

[0017] The pliers body 20 of the present invention is provided with pliers teeth 21 , and a through hole 22 is provided in the middle of the pliers body 20 , and the pin shaft 23 fixes the two pliers bodies 20 together through the through hole 22 .

[0018] The pliers handle 30 of the present invention is circular, and the middle part of the pliers handle 30 is provided with a notch 31 for hand insertion. The pliers handle 30 looks like a handle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com