Method for self-assembling micro-electromechanical system (MEMS) based on solder ball laser remelting process

A technology of laser remelting and self-assembly, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to deal with complex structures, inapplicability of heating and remelting, complex integration process of solder alloys, etc., and achieve self-assembly The effect of high precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

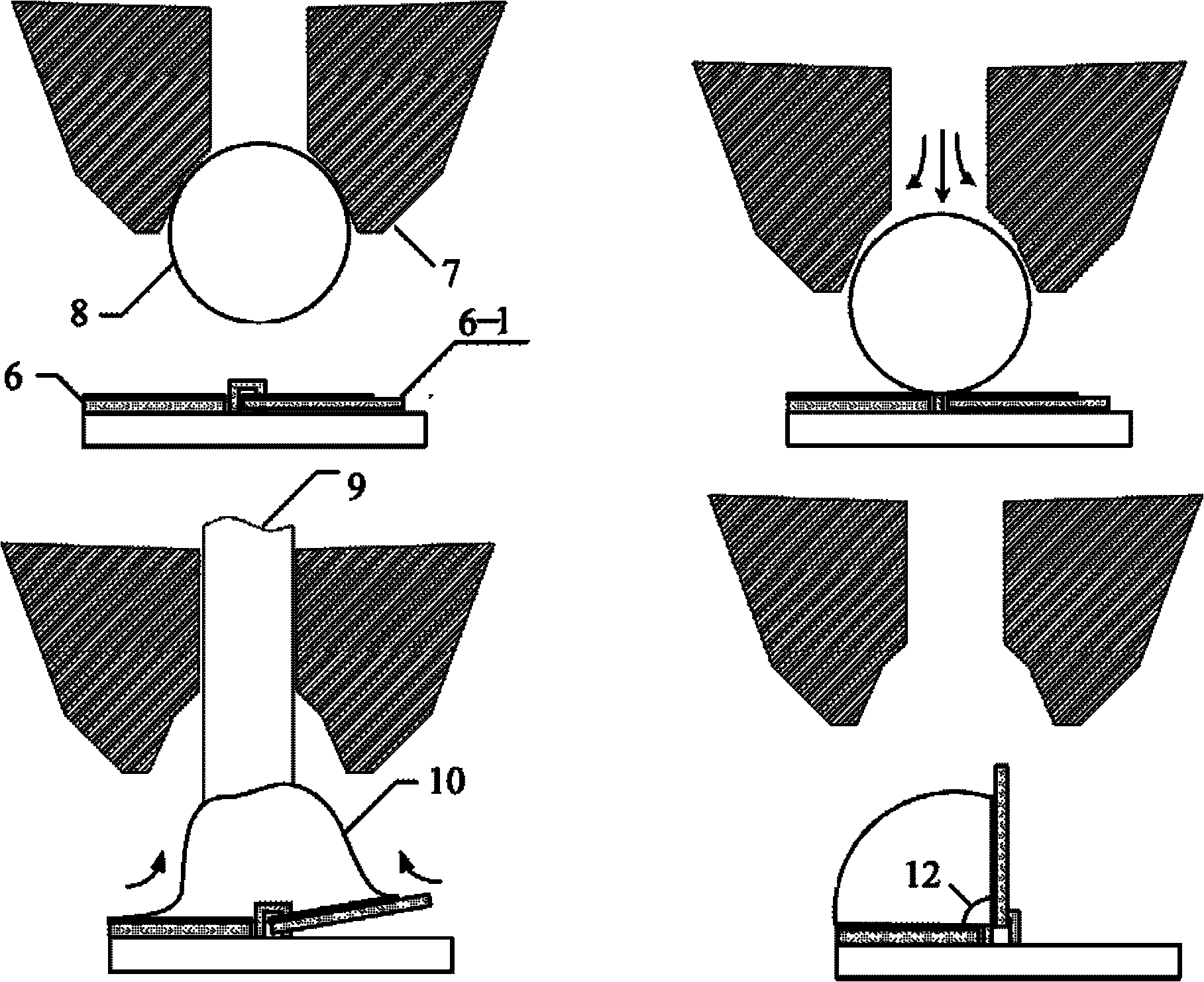

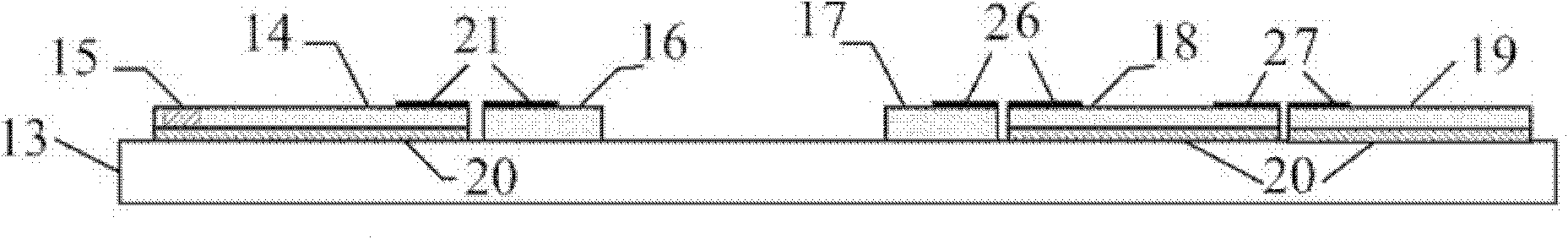

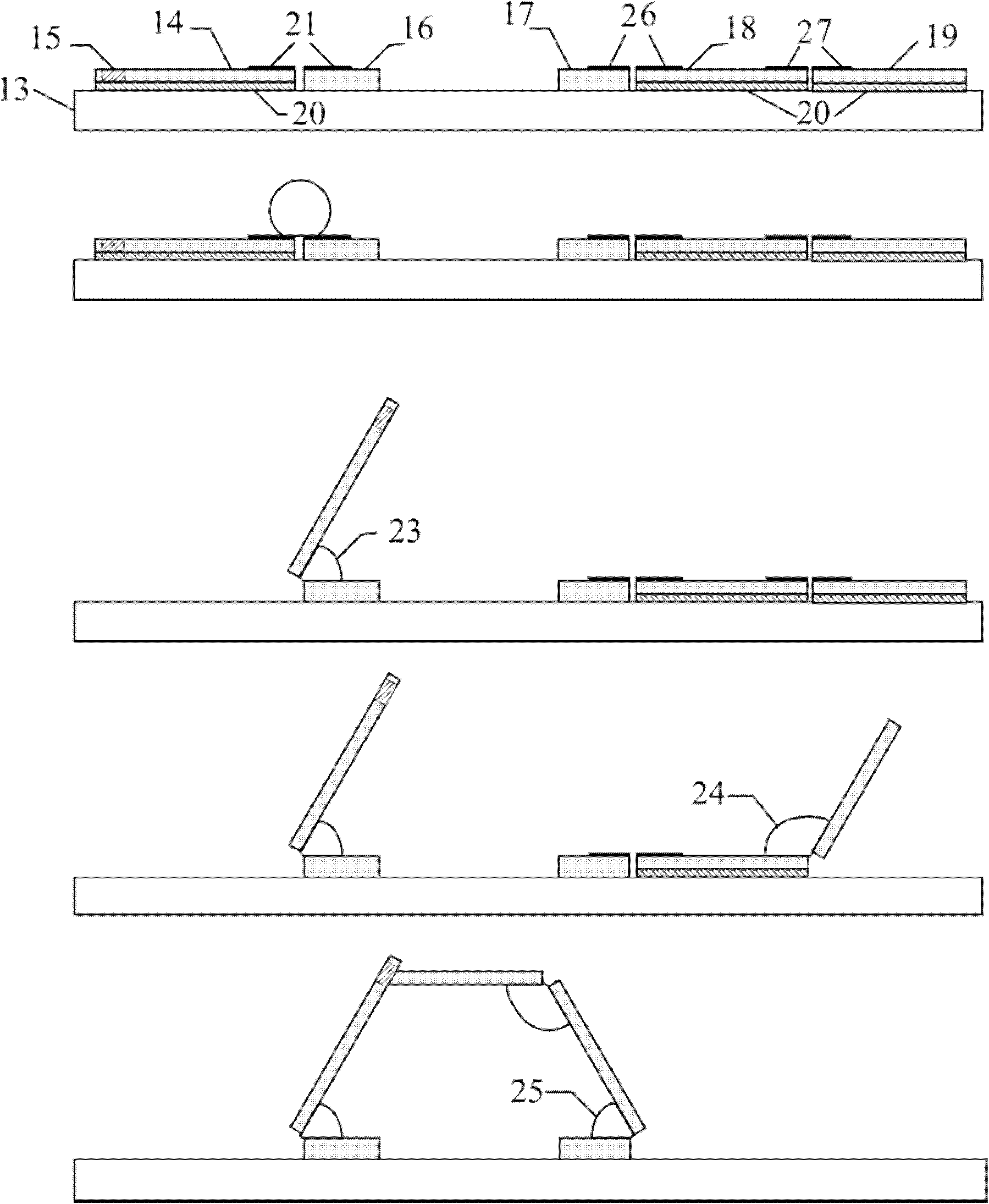

[0020] Specific implementation mode one: combine figure 1 Describe this embodiment, the method of this embodiment comprises the following steps: Step 1: the MEMS chip 6 with self-assembled basic structure that has completed sacrificial layer release is fixed on the clamping device, sucks solder alloy by suction nozzle device 7 ball 8;

[0021] Step 2: the suction nozzle device 7 releases the solder alloy ball 8 in the middle of the connection between the fixed microstructure and the movable microstructure pad on the MEMS chip;

[0022] Step 3: When the solder alloy ball 8 is released, the laser 9 is used to heat and remelt the solder alloy ball 8. After the solder alloy ball 8 is heated to the melting point, the molten solder wets the metal solder on the MEMS chip 6. Disk 6-1, the movable structure of the MEMS chip 6 realizes the turning motion under the action of the surface tension of the molten solder 10;

[0023] Step 4: By controlling the heating time and power of the ...

specific Embodiment approach 2

[0024] Specific embodiment two: the diameter of solder alloy ball 8 in the step 1 of the present embodiment is 200 μ m-400 μ m; 217°C; the power range of the laser used in step 4 is 3-15w, and the laser heating time is 80-800ms. The advantage of this step is that the rapid heating of the laser ensures the self-assembly efficiency. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: in step three of the present embodiment, the laser beam spot diameter is less than the diameter of the solder alloy ball 8, and only acts on the top of the solder alloy ball 8 to heat it. The advantage of this step is the characteristic of concentrated laser heating It ensures that the chip structure other than the solder ball is not damaged. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com