Full-automatic back flushing fiber bundle filter of slag flushing water of blast furnace and back flushing control method

A blast furnace slag flushing water and control method technology, applied to gravity filters, chemical instruments and methods, loose filter material filters, etc., can solve the problem of poor effect, fiber bundle filter can not effectively remove slag cotton suspended matter, filter The backwash of the filter can not be automatically controlled and other problems, so as to restore the filtering ability and ensure the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

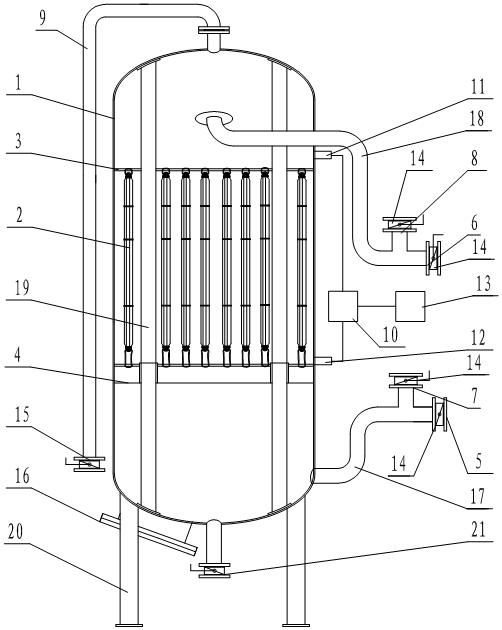

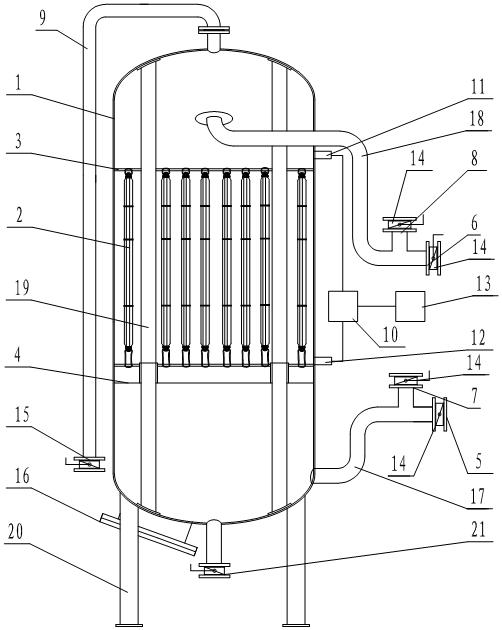

[0021] refer to figure 1 As shown, the fully automatic backwash fiber bundle filter for blast furnace slag flushing water in this embodiment includes a tank body 1 fixedly supported by support legs 20, and the lower part of the tank body 1 has a slag flushing water inlet 5 and a backwash water outlet 6. The upper part of the body 1 is connected with the slag flushing water outlet 7 and the backwashing water inlet 8, and the fiber bundle filter layer 2, the upper fixed filter plate 3 and the lower movable filter plate 4 arranged horizontally are arranged vertically in the tank body 1, and the upper fixed filter plate The periphery of the plate 3 is welded on the upper part of the inner wall of the tank body 1, the upper and lower ends of the fiber bundle filter layer 2 are respectively welded on the upper fixed filter plate 3 and the lower movable filter plate 4, and the top of the upper part of the tank body 1 is connected with scum Discharge pipe 9, meanwhile, the tank body 1...

Embodiment 2

[0028] Different from the above embodiment, in this embodiment, the set value of the pressure difference between the upper and lower parts of the fiber bundle filter layer 2 is 0.05MPa, the backwash water pressure is 0.4MPa, the backwash time is 20min, and the diameter of a single fiber bundle It is 20μm, the length is 2m, the porosity is 98%, and the distance between adjacent fibers in the fiber bundle is 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com