Self-cleaning tank type filtering separator

A filter separator and self-cleaning technology, which is applied in the field of tank-type filter separators and self-cleaning tank-type filter separators, can solve the problems of large floor area, easy blockage of filter bags, poor cleaning effect, etc. Small size, easy filtration process, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

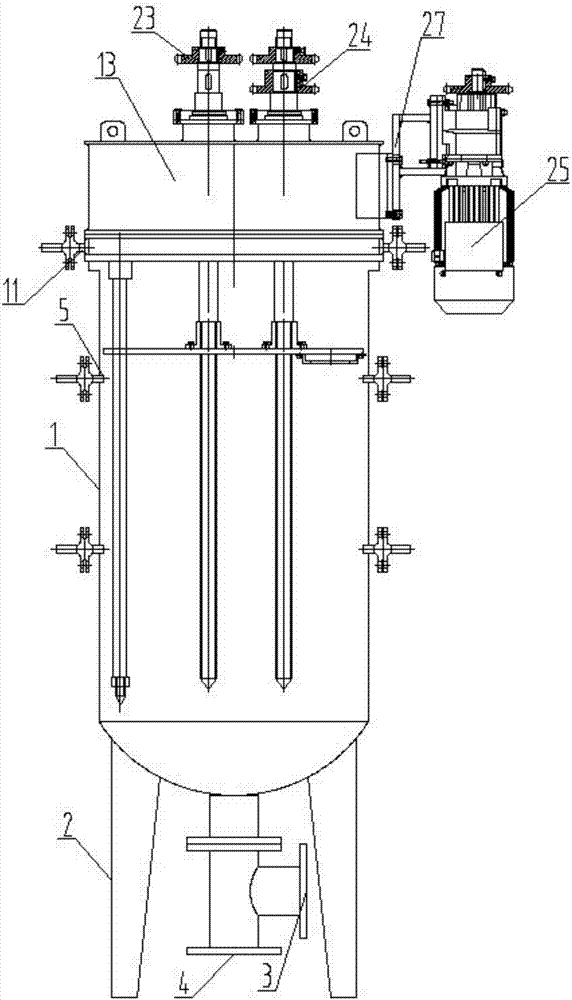

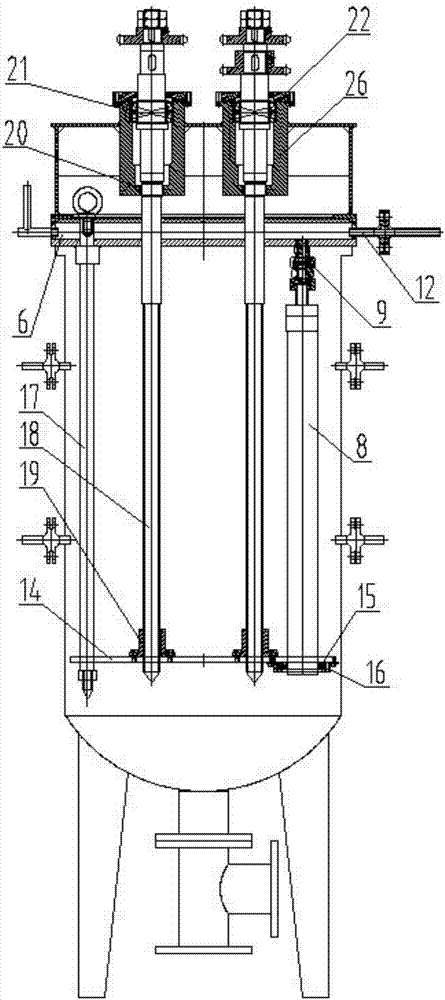

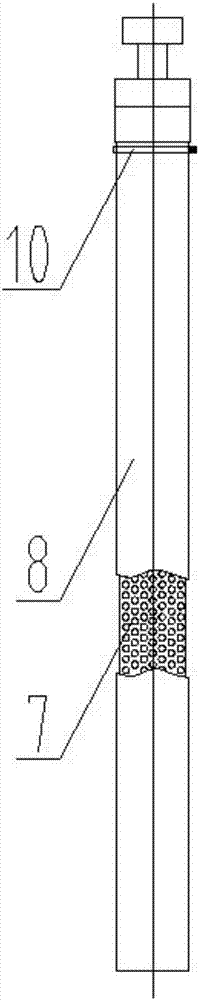

[0023] The technical solution is further described below in conjunction with reference to the accompanying drawings, examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or elements with the same or similar functions, but this description only It is used to explain the present invention, but should not be construed as a limitation of the present invention.

[0024] please see figure 1 , figure 2 , image 3 and Figure 4 , A self-cleaning tank filter separator provided by the present invention is characterized in that it includes a tank body 1, a filter assembly and a self-cleaning assembly.

[0025] The tank body 1 is provided with three legs 2, a slurry inlet 3, a slag outlet 4, and eight cleaning nozzles 5 (stainless steel material), and the cleaning nozzles 5 are evenly arranged in two layers.

[0026] The filter assembly includes a water tank 6, twelve filter tubes 7 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com