Preparation method of ZnO nano-rod array

A technology for nanorod arrays and preparation steps, which is applied in the field of preparation of ZnO nanorod arrays, can solve the problems of weak ultraviolet emission of ZnO nanorod arrays, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

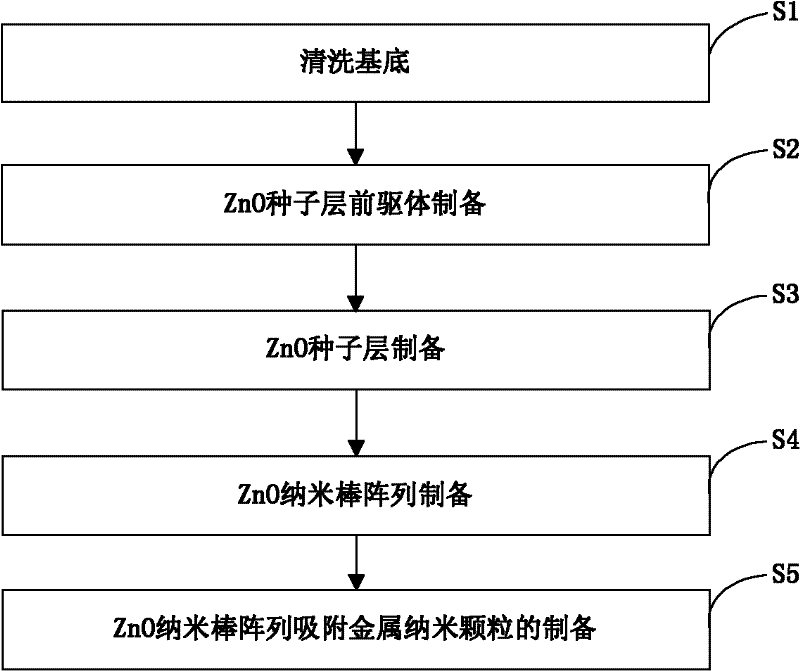

[0020] The invention provides a method for preparing a ZnO nanorod array, such as figure 1 As shown, the preparation process is as follows:

[0021] Step S1, substrate cleaning

[0022] Ultrasonic cleaning and drying of silicate glass, ITO conductive glass, FTO conductive glass, silicon wafer, sapphire and other substrate materials with acetone, alcohol, and deionized water in sequence;

[0023] Step S2, preparation of ZnO seed layer precursor solution

[0024] Add equimolar amounts of zinc salt (such as zinc acetate, zinc nitrate or zinc chloride, etc.) and ethanolamine (molar concentration is 0.025 ~ 0.3mol / L) into isopropanol in sequence, after fully stirring, seal and homogenize for 24 Hour;

[0025] Step S3, ZnO seed layer preparation

[0026] Transfer the substrate cleaned in step S1 to a homogenizer, add dropwise the ZnO seed layer precursor solution prepared in step S2, and after uniform dispersion, start the homogenizer and rotate at a speed of 2500 to 7500 rpm 1...

Embodiment 1

[0041] ZnO nanorod arrays with Ag nanoparticles adsorbed on the surface

[0042] (1) Base cleaning. The silicate glass is ultrasonically cleaned and dried with acetone, alcohol, and deionized water in sequence;

[0043] (2) ZnO seed layer preparation. First configure the seed layer precursor solution, dissolve zinc acetate and ethanolamine (0.025mol / L) in an equimolar amount in isopropanol in turn, after fully stirring, seal and homogenize for 24 hours; transfer the substrate to the homogenizer, drip Add the seed layer precursor solution, spin it at a speed of 2500 rpm for 20s after being uniformly dispersed; transfer the spin-coated substrate to a muffle furnace, and anneal for the first time at 350°C for 20min.

[0044] (3) Preparation of ZnO nanorods. First prepare the growth solution, dissolve equimolar zinc acetate and hexamethylenetetramine (0.1mol / L) in deionized water in turn to obtain the growth solution; immerse the substrate containing the seed layer in the growth ...

Embodiment 2

[0050] ZnO nanorod arrays with surface-adsorbed Au nanoparticles

[0051] (1) Base cleaning. The ITO conductive glass was ultrasonically cleaned and dried with acetone, alcohol, and deionized water in sequence.

[0052] (2) ZnO seed layer preparation. First configure the seed layer precursor solution, dissolve zinc acetate and ethanolamine (0.075mol / L) in an equimolar amount in isopropanol in turn, after fully stirring, seal and homogenize for 24 hours; transfer the substrate to the homogenizer, drip Add the seed layer precursor solution, and spin it at 6000 rpm for 10s after uniform dispersion; transfer the spin-coated substrate to a muffle furnace, and anneal for the first time at 600°C for 5min.

[0053] (3) Preparation of ZnO nanorods. First prepare the growth solution, dissolve equimolar zinc acetate and hexamethylenetetramine (0.05mol / L) in deionized water in turn to obtain the growth solution; immerse the substrate containing the seed layer in the growth solution, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com