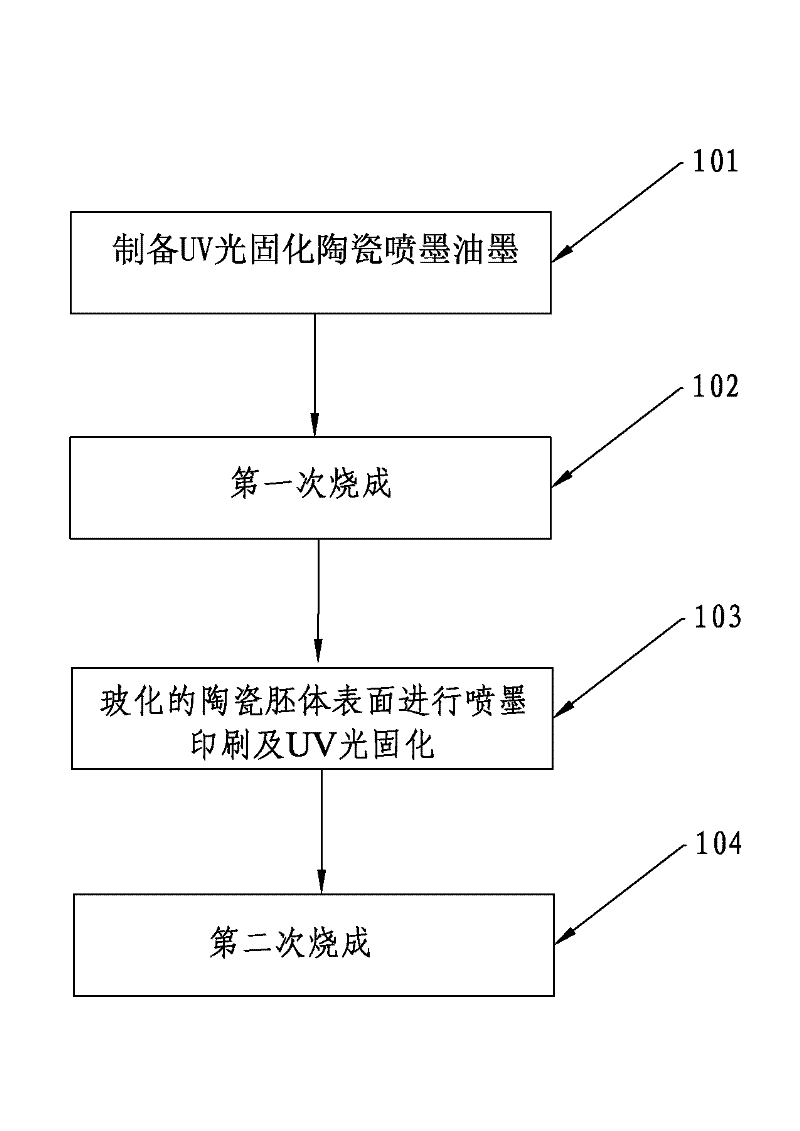

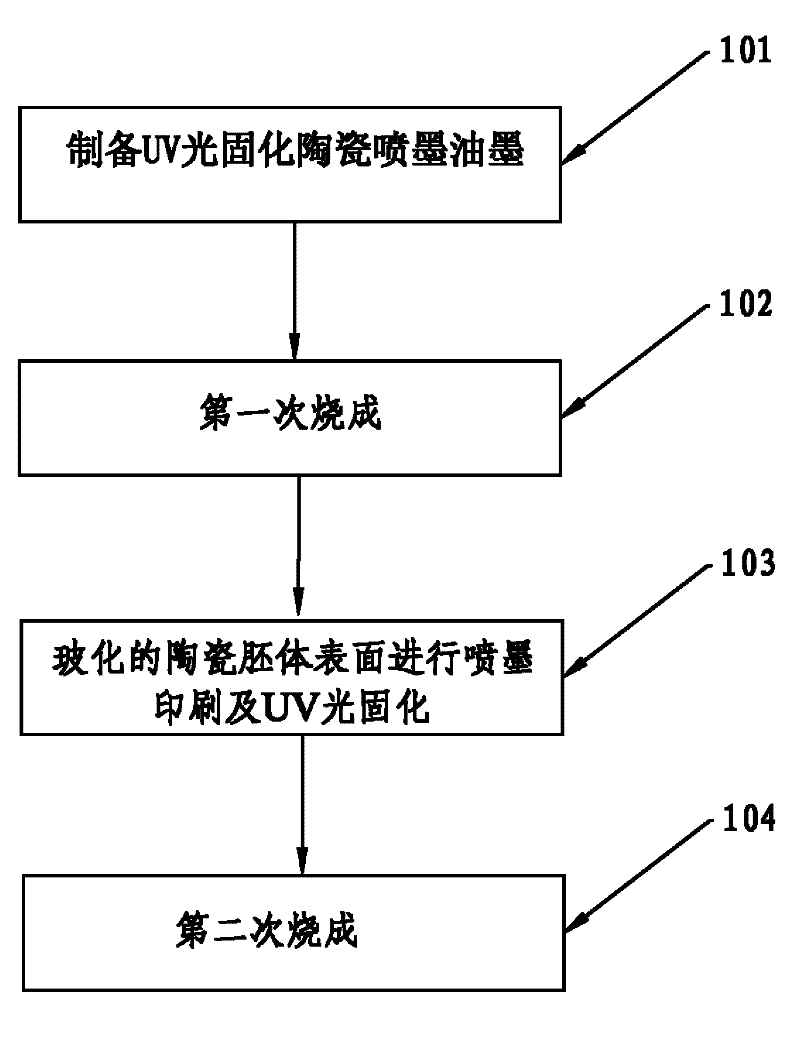

UV (ultraviolet) photo-cured ceramic inkjet ink and method for using same on ceramic surface for printing

A technology of ceramic inkjet and ceramic surface, applied in the field of ceramic surface printing and UV light curing ceramic inkjet ink, which can solve the problems of easy diffusion of ceramic ink, easy mutual diffusion of ceramic ink, and inability of inkjet printing of ceramic ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A kind of UV photocurable ceramic ink-jet ink of the present invention, it comprises following component by weight percentage:

[0105] Polyurethane acrylate 5~20%

[0106] Photopolymerization diluent 30~60%

[0107] Photoinitiator 0.5~3%

[0109] Solvent 0~40%

[0110] Ink additives 0.5~4%;

[0111] in:

[0112]Urethane acrylate is one or more mixtures of aliphatic urethane acrylate, aromatic urethane acrylate or epoxy acrylate;

[0113] The photopolymerizable diluent is a low-viscosity monofunctional acrylate and / or a low-viscosity difunctional acrylate;

[0114] The photoinitiator is a photoinitiator or a mixture of more than one photoinitiator of α-hydroxyalkyl phenones, α-amino ketone derivatives, acylphosphine oxides, hydrogen abstraction photoinitiators and co-initiators Photoinitiator;

[0115] In addition to ensuring that the emission spectrum of the light source matches the absorption spectrum of the photoinitiator, the ...

Embodiment 2

[0125] A UV light-curable ceramic inkjet ink in this embodiment is based on Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0126] UV photocurable ceramic inkjet ink, it comprises following components by weight percentage:

[0127] Polyurethane acrylate 5~10%

[0128] Photopolymerization diluent 40~55%

[0129] Photoinitiator 1~3%

[0131] Solvent 0~20%

[0132] Ink additives 2 to 4%.

Embodiment 3

[0134] A UV light-curable ceramic inkjet ink in this embodiment is based on Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0135] UV photocurable ceramic inkjet ink, it comprises following components by weight percentage:

[0136] Polyurethane acrylate 12~16%

[0137] Photopolymerization diluent 45~55%

[0138] Photoinitiator 2~3%

[0139] Ceramic pigment 20~30%

[0140] Solvent 0~10%

[0141] Ink additives 3~4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com