Continuous fiber reinforced polypropylene material and preparation method thereof

A technology of polypropylene material and continuous fiber, which is applied in the field of continuous fiber reinforced polypropylene material and its preparation, can solve the problems of unstable weight of parts, affecting the performance of parts, and difficult acceptance by customers, etc., and achieve easy control of glass fiber content , Improve online production capacity and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Continuous fiber reinforced polypropylene masterbatch (glass fiber content 40%) 50 parts

[0044] Fixed-length polypropylene pellets (7mm) 50 copies

[0045] The continuous fiber reinforced polypropylene masterbatch is prepared by the following method, which includes the following steps:

[0046] (1) Mixing preparation; 60 parts of polypropylene whose melt index is 25~65g / 10min (230℃, 2.16Kg), 0.5 part of silane coupling agent, 0.6 part of antioxidant, the antioxidant is composed of four (β -(3,5-di-tert-butyl-4hydroxyphenyl) propionic acid) pentaerythritol ester and tris(2,4-tert-butylphenyl) phosphite are mixed according to the weight of 1:2, 0.5 parts of ethyl EBS, 2 parts of maleic anhydride grafted polypropylene with a grafting rate of 1.0% are added to the high-mixer in turn, the mixing temperature is controlled at 40-60℃, and the mixing time is 3-5 Stop in minutes, then add the mixed materials to the hopper of the extruder for use;

[0047] (2) Preparation of continuou...

Embodiment 2

[0059] Continuous fiber reinforced polypropylene masterbatch (glass fiber content 40%) 50 parts

[0060] Polypropylene raw material 50 parts

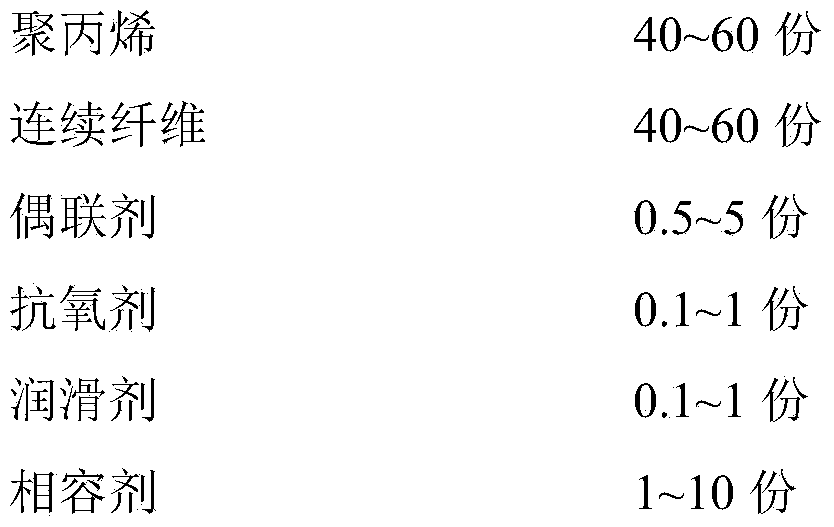

[0061] Continuous fiber reinforced polypropylene masterbatch, with a cutting length of 11-13mm and a particle size of 2.5-3.5mm, including the following components and parts by weight:

[0062] Polypropylene 60 parts

[0063] Continuous glass fiber 40 parts

[0064] Coupling agent 0.5 parts

[0065] Antioxidant 0.6 parts

[0066] Lubricant 0.5 parts

[0067] Compatibilizer 2 parts

[0068] The continuous fiber reinforced polypropylene masterbatch is prepared by the following method, which includes the following steps:

[0069] (1) Mixing preparation; 60 parts melt index is 25~65g / 10min (230℃, 2.16Kg), polypropylene with particle size 2.5-3.5mm, 0.5 part silane coupling agent, 0.6 part antioxidant, anti-oxidant The oxygen agent is made up of tetrakis (β-(3,5-di-tert-butyl-4 hydroxyphenyl) propionic acid) pentaerythritol ester and tris (2,4-tert-butyl ...

Embodiment 3

[0077] Continuous fiber reinforced polypropylene masterbatch (glass fiber content 40%) 50 parts

[0078] 50 parts of polypropylene pellets cut by ordinary pelletizer

[0079] Continuous fiber reinforced polypropylene masterbatch, with a cutting length of 11-13mm and a particle size of 2.5-3.5mm, including the following components and parts by weight:

[0080] Polypropylene 60 parts

[0081] Continuous glass fiber 40 parts

[0082] Coupling agent 0.5 parts

[0083] Antioxidant 0.6 parts

[0084] Lubricant 0.5 parts

[0085] Compatibilizer 2 parts

[0086] The polypropylene pellets cut by the ordinary pelletizer have a pellet length of 2.5-3.5mm and a particle size of 2.5-3.5mm, including the following components and parts by weight:

[0087] Polypropylene 100 parts

[0088] Antioxidant 0.6 parts

[0089] Lubricant 0.5 parts

[0090] The continuous fiber reinforced polypropylene masterbatch is prepared by the following method, which includes the following steps:

[0091] (1) Mixing preparation; 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com