Method for preparing environment-friendly pigment printing binder

A technology for adhesives and coatings, applied in the direction of adhesive types, ester copolymer adhesives, paper coatings, etc., can solve the problems of gloss, water resistance, and lack of fullness, and achieve excellent mechanical properties and simple preparation methods. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

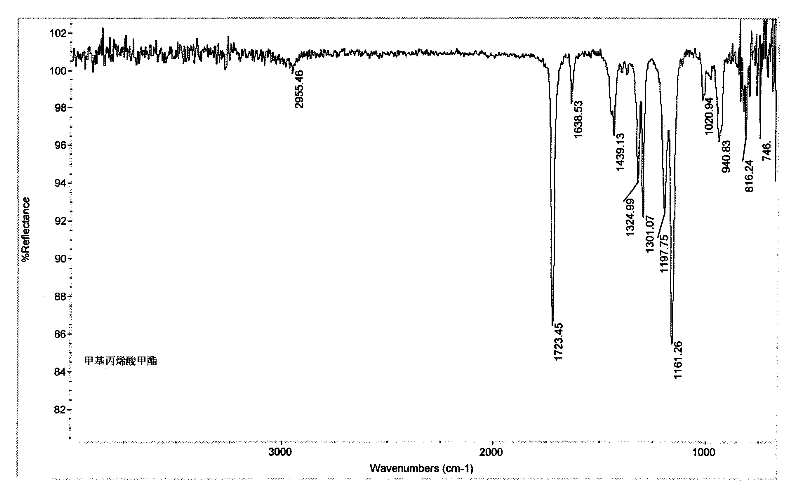

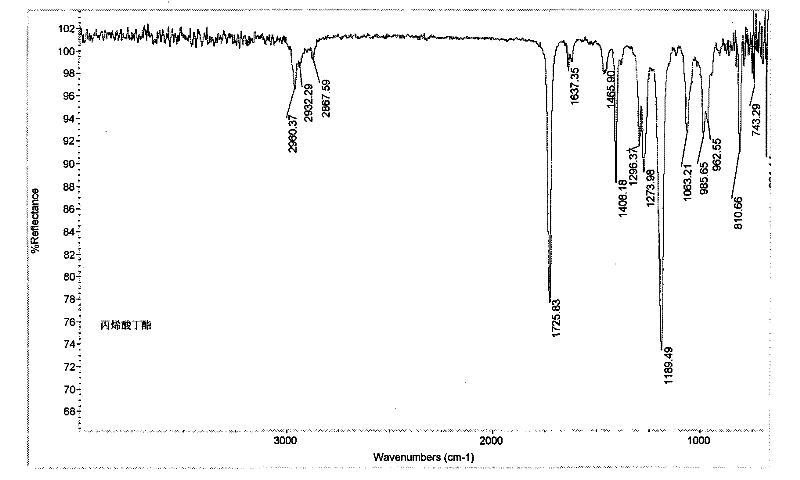

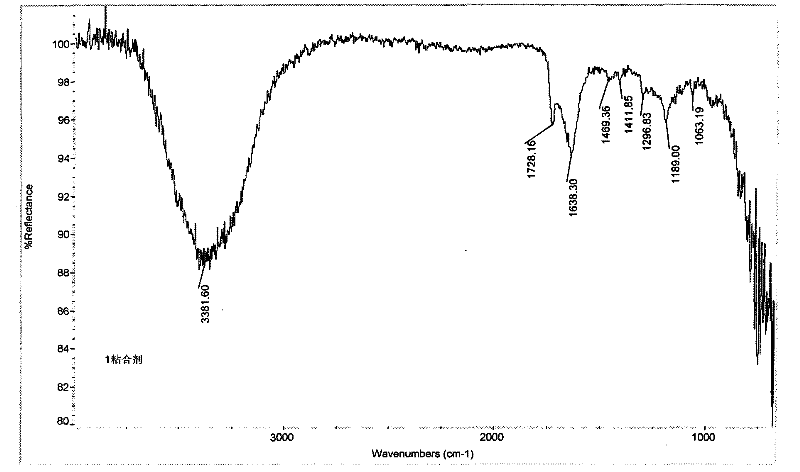

Image

Examples

Embodiment 1

[0020] Example 1 In a 500ml there-necked flask equipped with a stirrer, condenser, nitrogen protection and feeding device, add 22.5 grams of methyl methacrylate, 22.5 grams of butyl acrylate, 0.45 grams of acrylic acid, 4.5 grams of dodecylbenzenesulfonate Sodium bicarbonate and OP-10 emulsifier (mass ratio is 2:1) and a certain amount of deionized water (2 / 3 of the total water content), emulsified under the condition of reflux condensation at a temperature of 40°C for 90 minutes. Take 1 / 3 of the pre-emulsion in a three-necked flask, add the remaining deionized water and 1 / 3 of the initiator, stir, reflux and condense at 80°C for preparation, and react for 120 minutes until the emulsion is light blue. Put the remaining pre-emulsion in the dropping funnel, slowly drop it into the reactor, and add the remaining initiator to prepare the adhesive. After the dropping, add NaHCO 3 Adjust the pH value of the aqueous solution to 7-7.5, keep it warm for 60 minutes and take it out. The...

Embodiment 2

[0021] Embodiment 2 In the there-necked flask that stirrer, condenser tube, nitrogen protection and feeding device are equipped with in 500ml, add 22.5 gram methyl methacrylates, 22.5 gram butyl acrylates, 0.45 gram acrylic acid, 4.5 gram nonionic emulsifiers and A certain amount of deionized water (2 / 3 of the total water content) is emulsified for 90 minutes under the condition of reflux condensation at a temperature of 40°C. Take 1 / 3 of the pre-emulsion in a three-necked bottle, assuming the remaining deionized water and 1 / 3 of the initiator, stir, reflux and condense to prepare at 80°C, react for 120 minutes, and put the remaining pre-emulsion in the drop In the funnel, slowly drop into the reactor, and add the remaining initiator to prepare the adhesive. After the dropwise addition, add NaHCO 3 Adjust the pH value of the aqueous solution to 7-7.5, keep it warm for 60 minutes and take it out. The solid content of the obtained aqueous emulsion is 40%, the latex particle siz...

Embodiment 3

[0022] Example 3 In a 500ml there-necked flask equipped with a stirrer, condenser, nitrogen protection and feeding device, 17.5 grams of methyl methacrylate, 5 grams of styrene, 22.5 grams of butyl acrylate, 0.45 grams of acrylic acid, 4.5 grams of non An ionic emulsifier and a certain amount of deionized water (2 / 3 of the total water content) are emulsified for 90 minutes under the condition of reflux condensation at a temperature of 40°C. Take 1 / 3 of the pre-emulsion in a three-necked bottle, assuming the remaining deionized water and 1 / 3 of the initiator, stir, reflux and condense to prepare at 80°C, react for 120 minutes, and put the remaining pre-emulsion in the drop In the funnel, slowly drop into the reactor, and add the remaining initiator to prepare the adhesive. After the dropwise addition, add NaHCO 3 Adjust the pH value of the aqueous solution to 7-7.5, keep it warm for 60 minutes and take it out. The solid content of the obtained aqueous emulsion is 40%, the late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com