Succinic acid separating apparatus and method based on full membrane separation system

A membrane separation system and separation device technology, applied in semi-permeable membrane separation, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve problems such as insufficient coupling between separation process and fermentation process, and achieve reasonable unit operation design , The effect of short process route and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

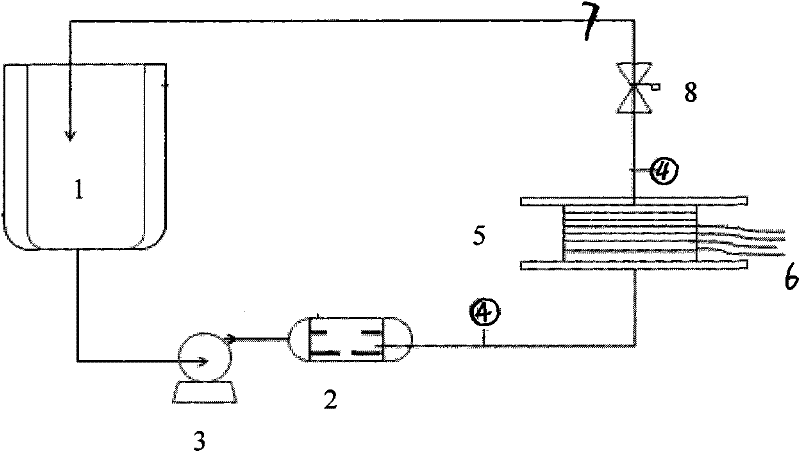

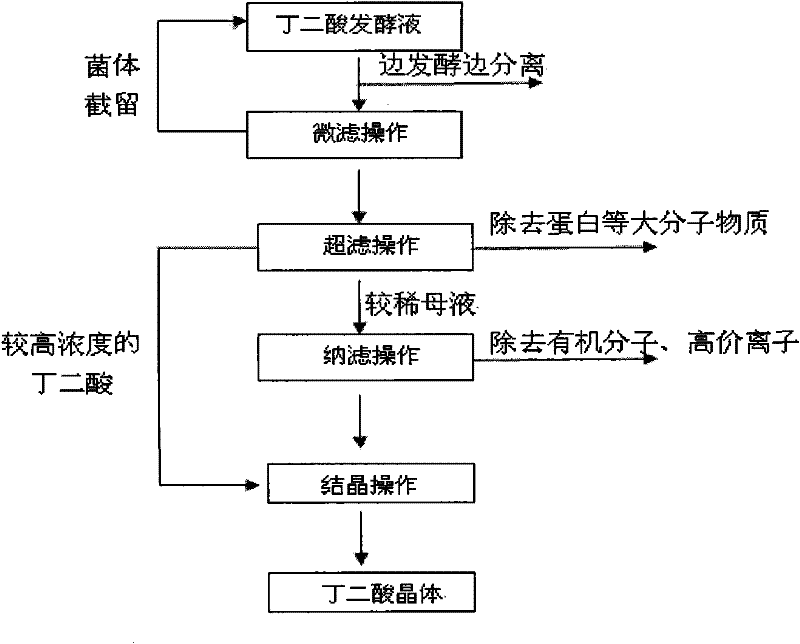

Method used

Image

Examples

Embodiment 1

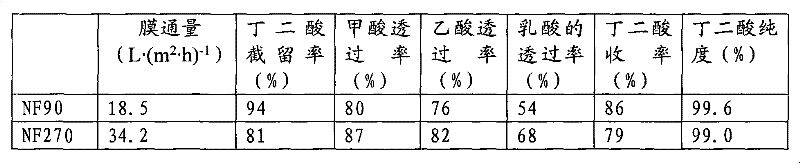

[0044] Using glucose as carbon source, Actinobacillus succinate BE-1 is the succinic acid fermentation broth produced by the fermentation of the production strain, in which the concentration of succinic acid is 76g / L, the concentration of formic acid is 8g / L, and the concentration of acetic acid is 10g / L , the concentration of lactic acid is 5g / L, the amount of residual sugar is less, and the pH of the fermentation broth is 6.8.

[0045] After the fermentation broth is operated by microfiltration membrane, the removal rate of bacteria is 95%, and the removal rate of protein is 35%. The microfiltration operation adopts hollow fiber microfiltration membrane. The organic membrane adopts the method of cross-flow operation, and the operating temperature is 25°C. The obtained microfiltration permeate is subjected to ultrafiltration operation. The ultrafiltration operation adopts hollow fiber membrane equipment. The membrane material is organic membrane. ℃, the operating pressure is...

Embodiment 2

[0048] Using glucose as the carbon source, Actinobacillus succinate BE-1 is the succinic acid fermentation broth produced by the fermentation of the production strain, in which the concentration of succinic acid is 85g / L, the concentration of formic acid is 10g / L, and the concentration of acetic acid is 15g / L , the concentration of lactic acid is 3g / L, there is no residual sugar, and the pH of the fermentation broth is 6.8.

[0049] The fermentation broth is processed by two processes.

[0050] Process 1: After the fermentation broth is operated by microfiltration membrane, the removal rate of bacteria is 93%, and the removal rate of protein is 32%. The microfiltration operation adopts hollow fiber microfiltration membrane, and the pore size of the microfiltration membrane is 0.1 μm. The membrane material is organic membrane, and the cross-flow operation method is adopted, and the operating temperature is 25°C. The obtained microfiltration permeate is subjected to ultrafiltra...

Embodiment 3

[0054] The succinic acid fermentation broth is fermented with glucose as the carbon source and genetically engineered Escherichia coli as the production strain, in which the concentration of succinic acid is 92g / L, the concentration of formic acid is 12g / L, the concentration of acetic acid is 17g / L, and the concentration of lactic acid The concentration is 5g / L, no residual sugar, and the pH of the fermentation broth is 6.7.

[0055] The process of fermentation liquid treatment is as follows: the fermentation liquid is subjected to microfiltration operation, and the microfiltration operation adopts hollow fiber microfiltration membrane. The pore size of the microfiltration membrane is 0.1 μm. The temperature is 25°C. After microfiltration, the removal rate of bacteria is 94%, and the removal rate of protein is 35%. The microfiltration permeate is subjected to ultrafiltration operation. The ultrafiltration operation adopts hollow fiber membrane equipment, and the membrane materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com