Multi-box pulse-type high-pressure circulating cleaner

A high-pressure cycle, pulsed technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of complex and expensive equipment, insufficient flushing time, waste of manpower and material resources, etc., and achieve simple equipment structure. , the effect of saving manpower and material resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

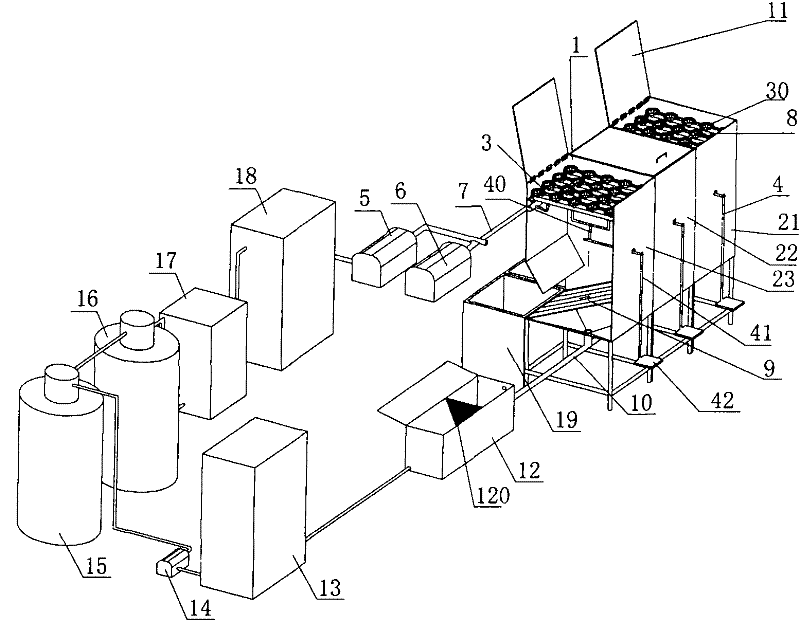

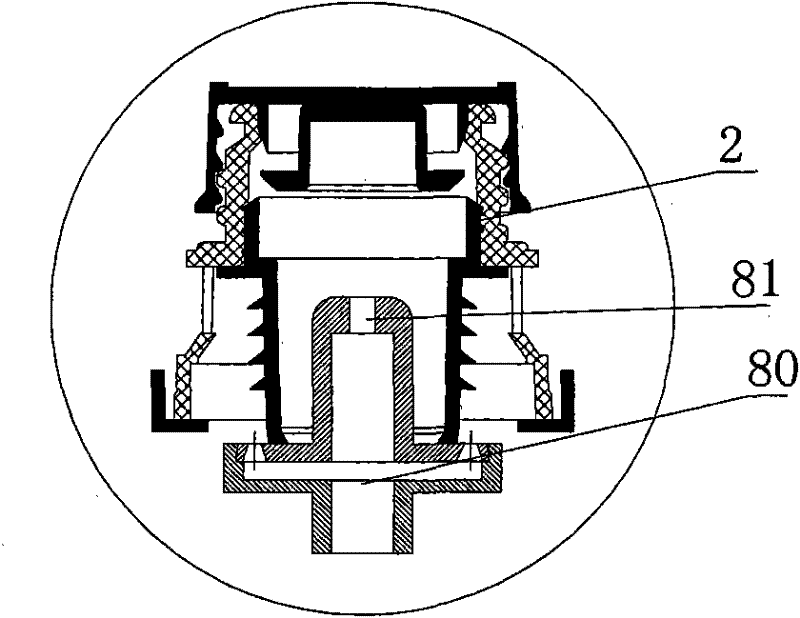

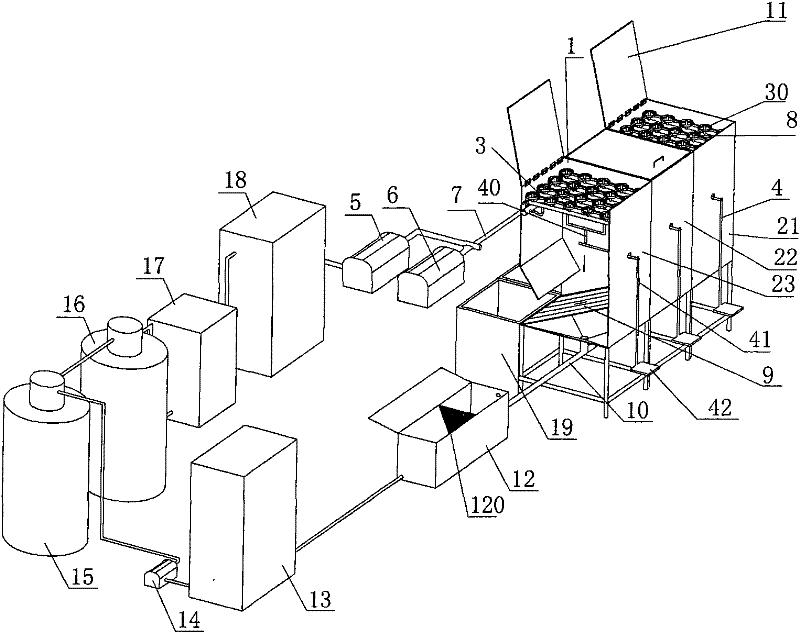

[0015] Such as figure 1 and figure 2 As shown, a multi-box pulse type high-pressure cycle cleaning machine of the present invention includes more than two boxes 1, and a discharge tray 3 for placing the container 2 arranged in the box 1, and a discharge tray 3, a plurality of trays 30 densely arranged in a matrix, and a discharge device 4 arranged under the discharge tray 3 for unloading, and a delivery pump 5 for providing high-pressure water, and a delivery pump 5 connected to the delivery pump 5 High-pressure pulse pump 6, and the water inlet pipe 7 that is connected with high-pressure pulse pump 6, and be arranged on the water inlet pipe 7, be positioned at the water spray nozzle 8 in the pallet 30 of discharge tray 3, and be arranged on the discharge below, The grid 9 used to separate the container 2 and water, the outlet pipe 10 arranged under the grid 9, the filter device connected to the outlet pipe 10, and the linkage used to control the switch of the multi-box puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com