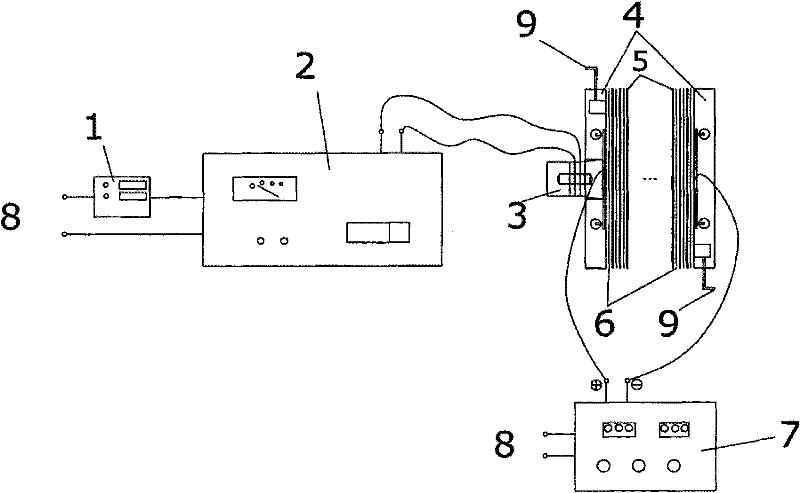

Electrodialyzer with ultrasonic function

An electrodialyzer and functional technology, applied in the field of electrodialyzer, can solve the problems of energy consumption, time consumption, pollution and effective cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

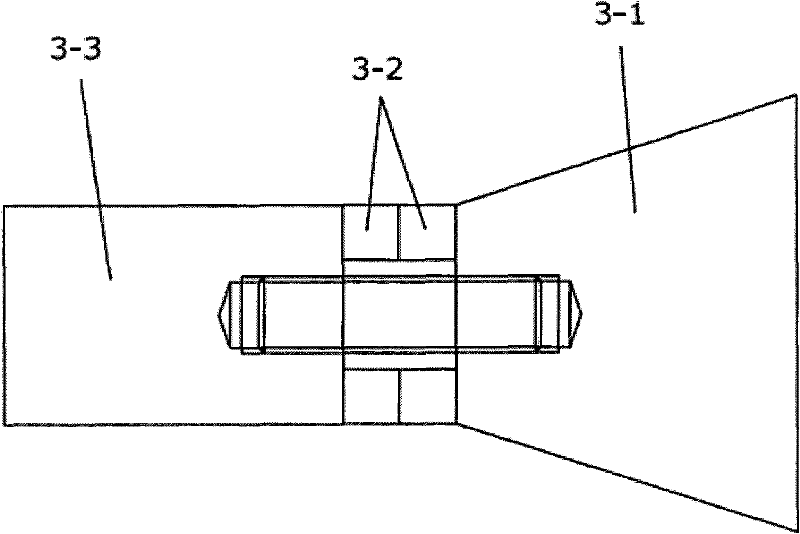

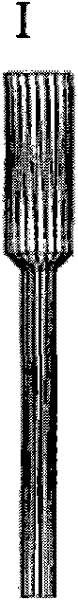

[0073] The conventional anode electrode plate is used as the anode plate, such as Figure 4b The electrode plate on which the ultrasonic transducer is installed is the cathode plate, and the maximum diameter of the metal block at the front end of the ultrasonic transducer installed is 45 mm. The center of the front metal block of the ultrasonic transducer and the geometric center of the effective surface of the electrode plate Overlapping, the ultrasonic transducer 3 and the electrode plate electrode material 4-2 are bonded with 302 modified acrylate adhesive. The frequency of the ultrasonic transducer is 40kHz, the ultrasonic output power is 40W, the effective surface size of the electrode plate is 5cm×10cm, and the effective membrane area is 50cm 2 , the film surface power is 0.8W / cm 2 .

[0074] The commercially available ZN48 electromagnetic relay is used for timing control; the ultrasonic generator matched with the above-mentioned ultrasonic transducer is adopted; the o...

Embodiment 2

[0077] Use the same online ultrasonic electrodialyzer as in Example 1 to carry out acid-base regeneration treatment on the fermentation waste liquid.

[0078] The operating voltage of electrodialysis is 30V, constant pressure operation; the initial liquid of the acid chamber is 0.05mol / L dilute sulfuric acid 300mL, the initial liquid of the alkali chamber is 0.1mol / L dilute ammonia water 300mL, the initial liquid of the material chamber is sterilized monosodium glutamate, etc. Electrode mother solution 300mL, the initial solution of the electrode compartment is 300mL of anhydrous sodium sulfate solution of 30g / L. The set temperature of the constant temperature water bath was 30°C. The ultrasonic mode controlled by the electromagnetic relay is as follows: 60s is a cycle, the ultrasonic time is 15s, and the non-ultrasonic time is 45s until the end of the electrodialysis operation. The measured and calculated electrodialysis process parameters are as follows: the average current...

Embodiment 3

[0080] The conventional cathode electrode plate is used as the cathode plate, and the mode of coupling the ultrasonic transducer and the horn with the anode plate as shown in Figure 4d is adopted. The number of ultrasonic transducers installed is 4, and the effective surface size of the electrode plate is 10cm×20cm, evenly distributed within the effective area, the maximum diameter of the metal block at the front end of the ultrasonic transducer installed is 45mm, and the lower end of the horn is at the geometric center of the equally divided effective surface, such as Figure 6b As shown; 302 modified acrylate adhesive is used for bonding between the ultrasonic transducer 3 and the upper end of the horn 3-4. The frequency of the ultrasonic transducer is 40kHz, the ultrasonic output power is 40W, and the effective membrane area is 200cm 2 , the film surface power is 0.8W / cm 2 .

[0081] The commercially available ZN48 electromagnetic relay is used for timing control; the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com