Wet chemical cleaning method

A wet chemistry, oxide layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increasing process cost and increasing process time, increasing process cost, shortening process time, and eliminating the formation of water. trace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

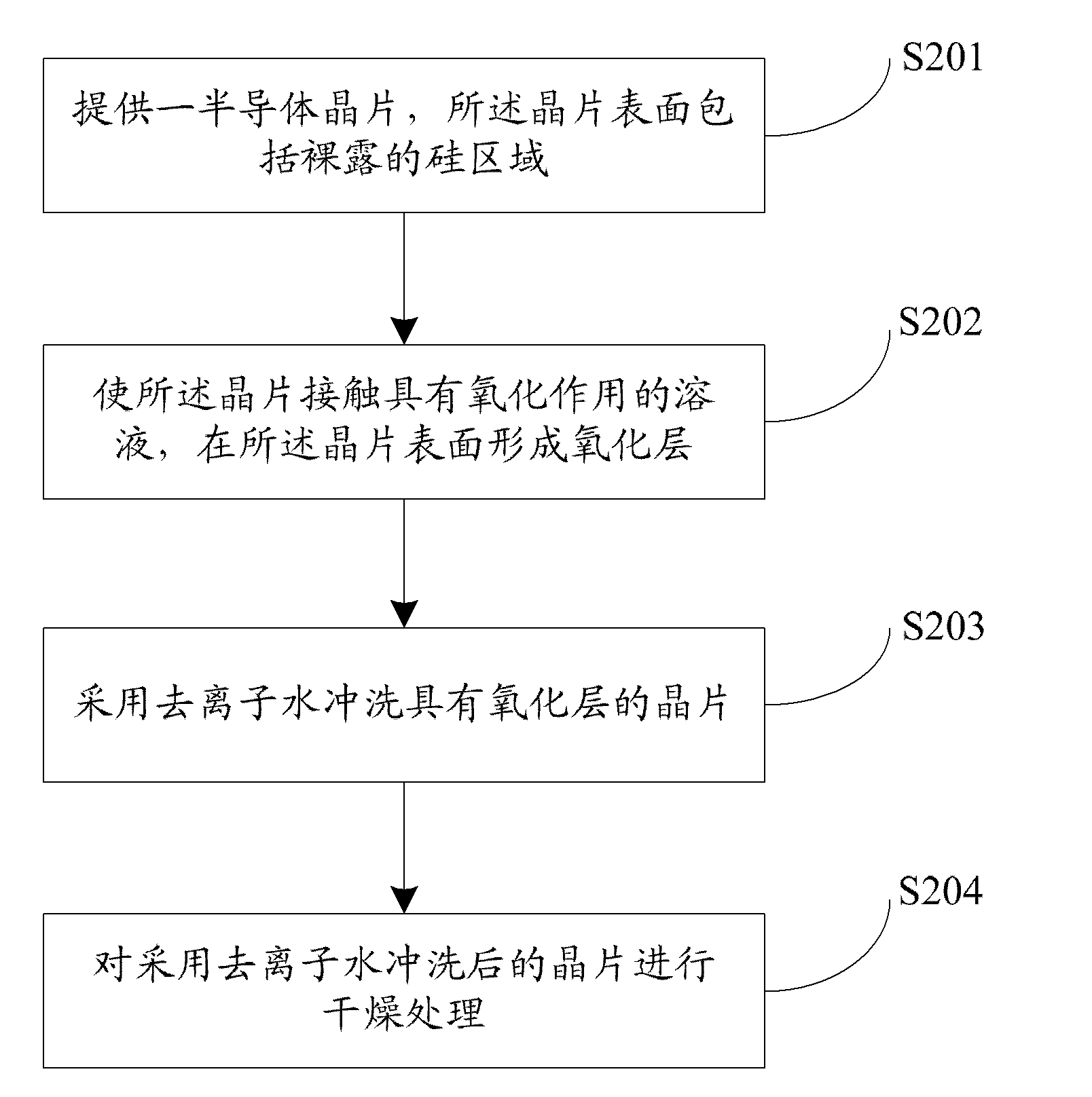

[0033] Based on the above reasons, the flow chart of the wet chemical cleaning method provided in this embodiment is as follows figure 1 As shown, the method includes the following steps:

[0034] Step S101: providing a semiconductor wafer, the surface of the wafer includes a bare silicon region;

[0035] The semiconductor wafer described in this embodiment may include semiconductor elements, such as silicon or silicon germanium (SiGe) with a single crystal, polycrystalline or amorphous structure, or a mixed semiconductor structure, such as silicon carbide; it may also be epitaxial silicon on insulator (silicon on insulator, SOI). Furthermore, the semiconductor wafer can also comprise other materials, such as multilayer structures of epitaxial layers or buried layers. In addition, the above-mentioned semiconductor wafer also includes a plurality of integrated circuits fabricated thereon, and these integrated circuits may be at any stage in the process. Therefore, the above-m...

Embodiment 2

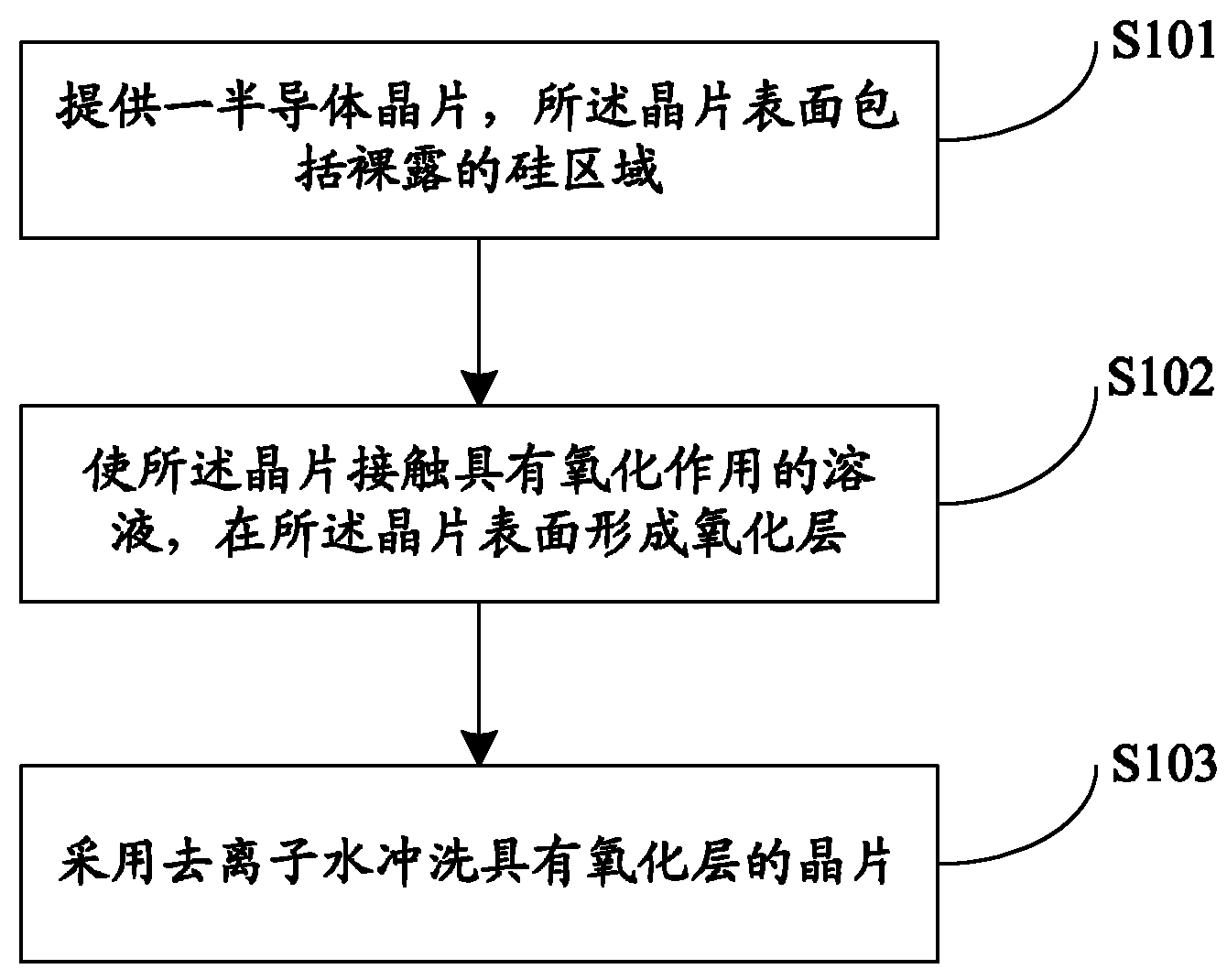

[0045] The flow chart of the wet chemical cleaning method provided in this embodiment is as follows figure 2 As shown, step S204 is added compared to Embodiment 1: dry the wafer after rinsing with deionized water, which can be dried by rotary drying, or by isopropanol vapor, or by other methods. For drying treatment, spin-drying is preferred in this embodiment, but which method should be used for drying should be comprehensively determined by the size and surface characteristics of the wafer and subsequent processes.

[0046] The oxidation solution in this example includes H 2 o 2 and H 2 O, and H 2 o 2 and H 2 O is mixed in a volume ratio of 1:5-50, preferably H 2 o 2 and H 2 O is mixed in a volume ratio of 1:10-40, more preferably H 2 o 2 and H 2 O is mixed in a volume ratio of 1: 20-30, and the concentration of the solution can be selected to match the contact time and the contact mode between the wafer and the solution with oxidation, as long as the semiconduct...

Embodiment 3

[0049] The difference between the wet chemical cleaning method provided in this example and the previous example is the selection of the solution with oxidation function. The solution with oxidation function in this example includes NH 4 OH, H 2 o 2 and H 2 O, where NH 4 OH, H 2 o 2 and H 2 O is mixed in a volume ratio of 1:1-2:5-80, preferably NH 4 OH, H 2 o 2 and H 2 O is mixed by volume ratio 1: 1-2: 5-7, promptly selects the No. 1 standard cleaning solution (SC-1) in the RCA cleaning for use, because what selected is the solution commonly used in the existing production process, so compared with the prior art The process cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com