Vertical hydride vapor phase epitaxy growth system

A hydride vapor phase, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of clogging the pipeline, terminating the reaction, hindering the further progress of the reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

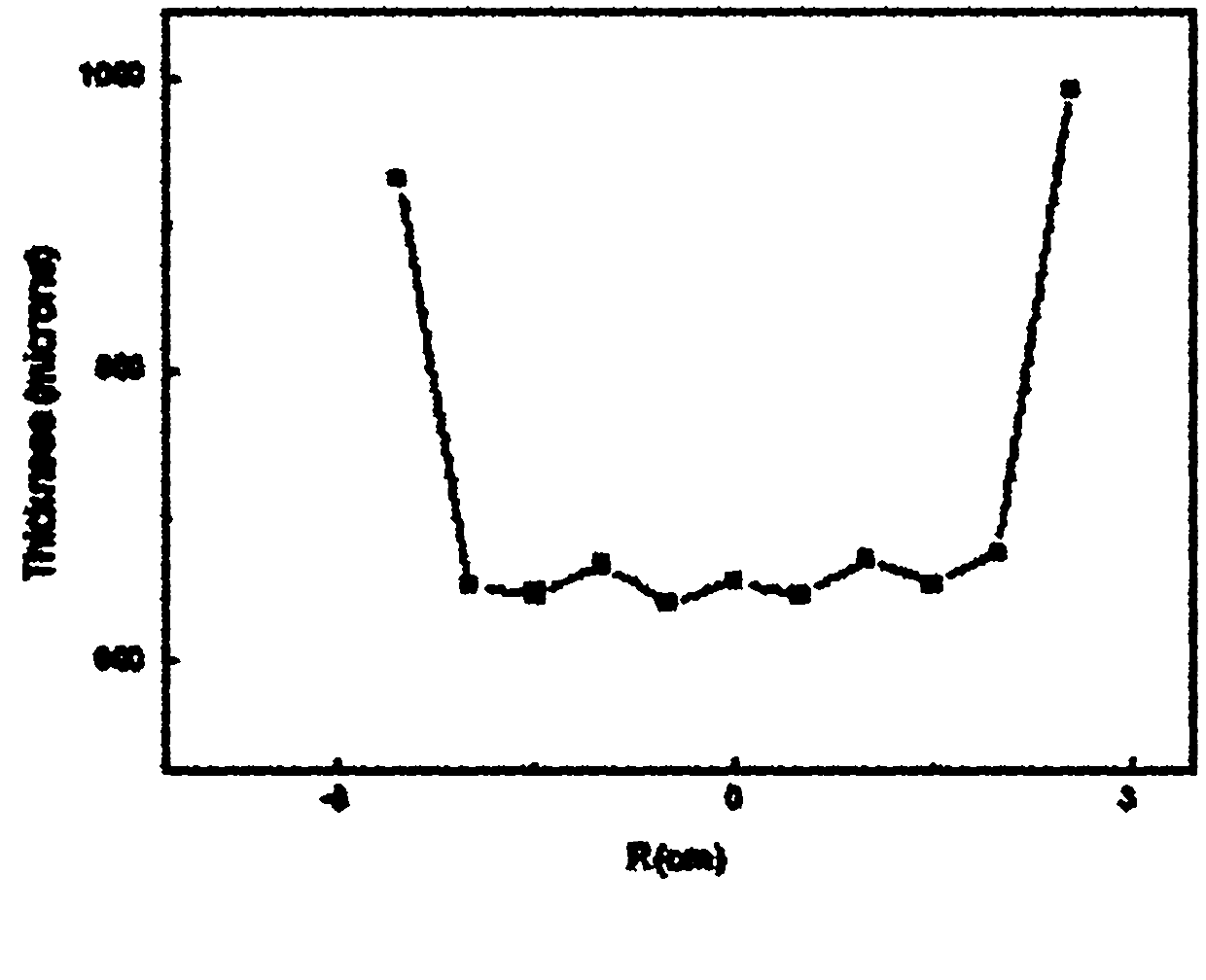

[0018] The invention includes a reaction chamber, a graphite support, an epitaxial growth substrate, a heating system and an exhaust gas treatment system. The graphite support is arranged in the growth area of the reaction chamber, the reaction chamber is a vertical structure, and the height of the growth area is 1 to 5 cm. , multiple epitaxial growth substrates are set above the graphite support or inverted below the graphite support, and the exhaust gas outlet is located at the lower part of the reaction chamber, wherein the reaction chamber is an axial sleeve structure, which is composed of a chamber tube and a gas conduit socket. , the gas conduit is located at the entrance of the chamber tube, the interior of the entrance of the gas conduit is a multi-channel separated gas path structure, and the multi-channel separated gas paths are evenly distributed in the axial direction, and are used to send the reaction gas to the epitaxial growth substrate in the growth area , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com