Method and mould arrangement for manufacturing articles with the help of a mould

A mold manufacturing and mold technology, which is applied in the field of manufacturing articles and mold devices by means of molds, can solve the problems of expensive molds and can only be manufactured in large quantities, and achieve the effect of short manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

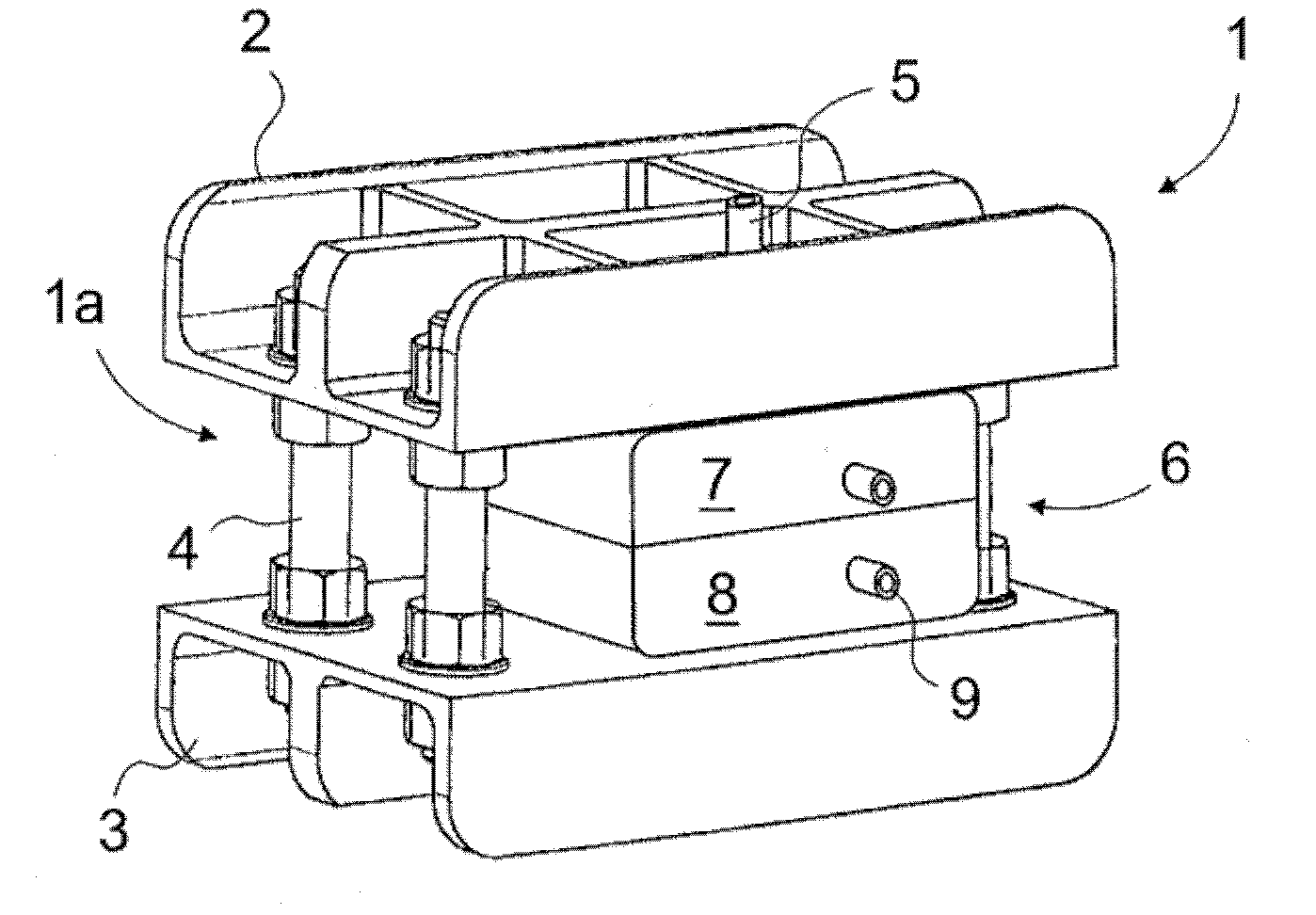

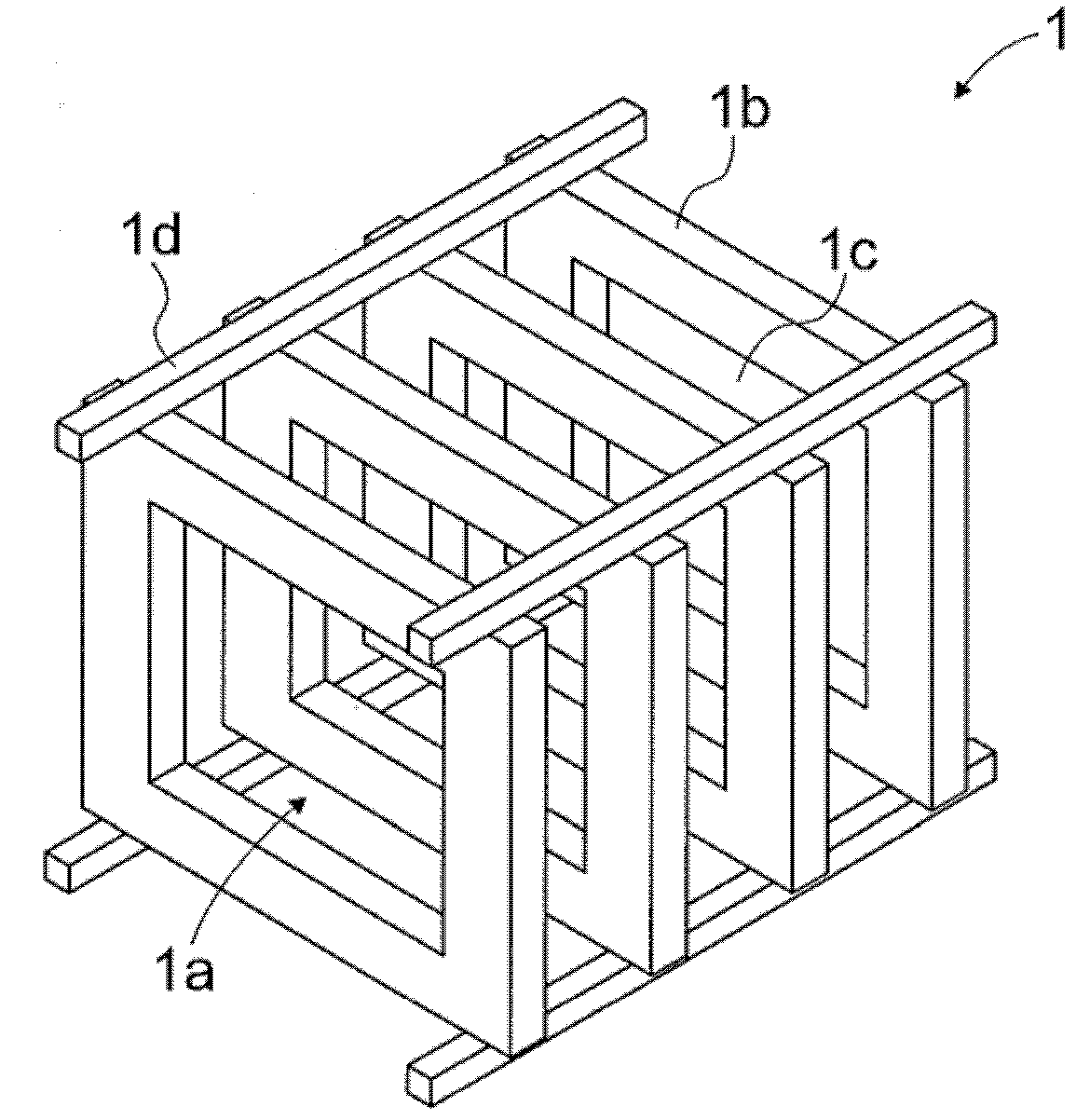

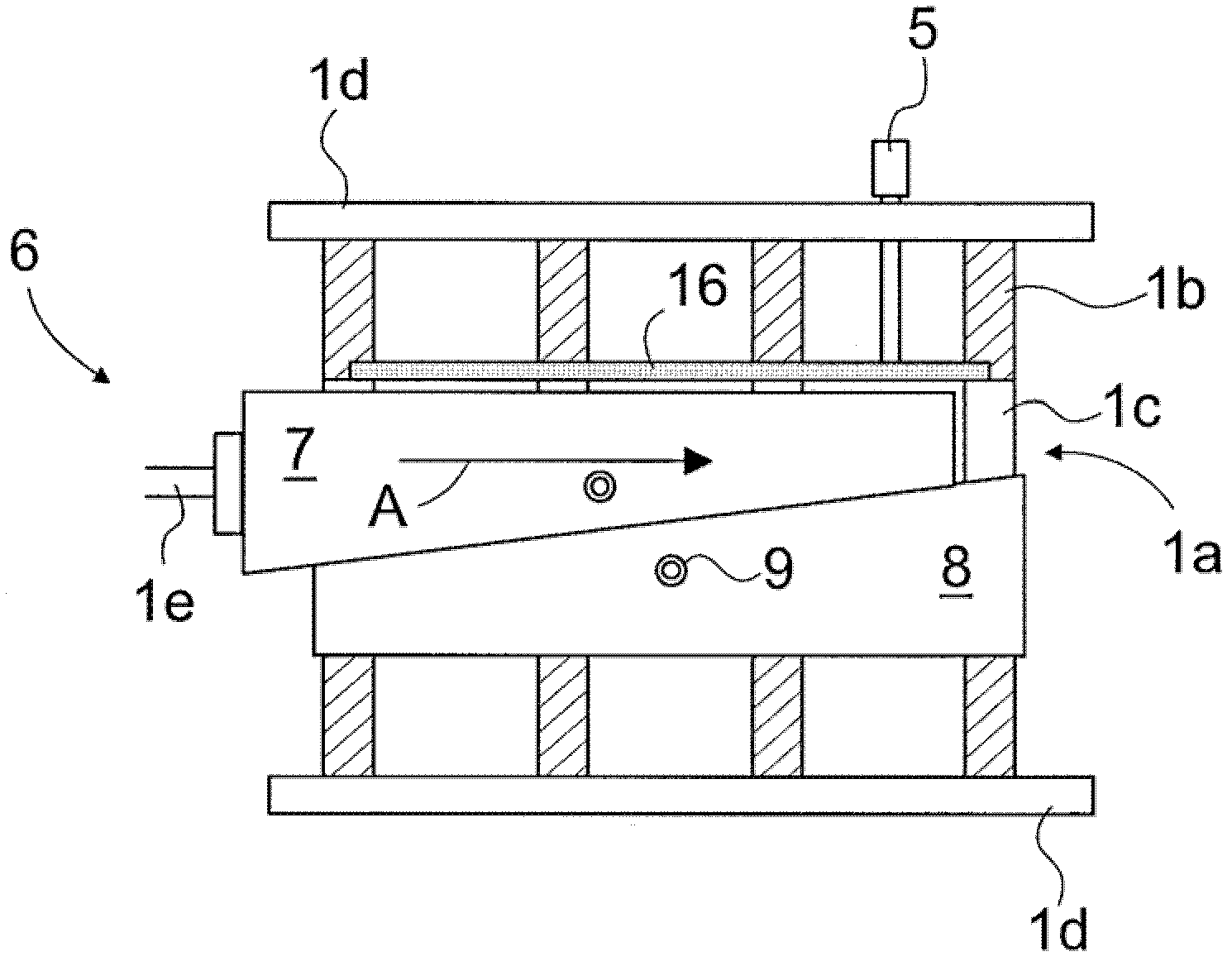

[0027]A hydraulic pressing unit for the manufacture of different products, for example from one material and various composite and laminated materials, by different compression methods such as compression molding, vacuum forming and injection molding products manufactured by the method. The solution according to the invention comprises a strong pressure-resistant frame 1 and also a pressure chamber 6 to be arranged inside it, in which the mold is surrounded by high pressure and temperature, and wherein the bottom chamber part 8 of the pressure chamber 6 can be App is replaced. This solution also includes the use of high temperatures, so that post-processing of the product to be manufactured with an autoclave is avoided. Using the solution according to the invention techniques known in particular from plastics molding technology and already used, for example, in injection molding moulds, are applied.

[0028] figure 1 A simplified oblique front view from above of a device ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com