Method for producing low sulfur gasoline by using by inferior gasoline fractions

A low-quality gasoline and gasoline technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problem of affecting the activity and stability of hydrodesulfurization catalysts, increase the depth of hydrodesulfurization of heavy fractions, and accelerate the shrinkage of diolefins Synthetic coke and other problems, to achieve the effect of reducing the risk of condensation into coke, inhibiting carbon deposition, and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

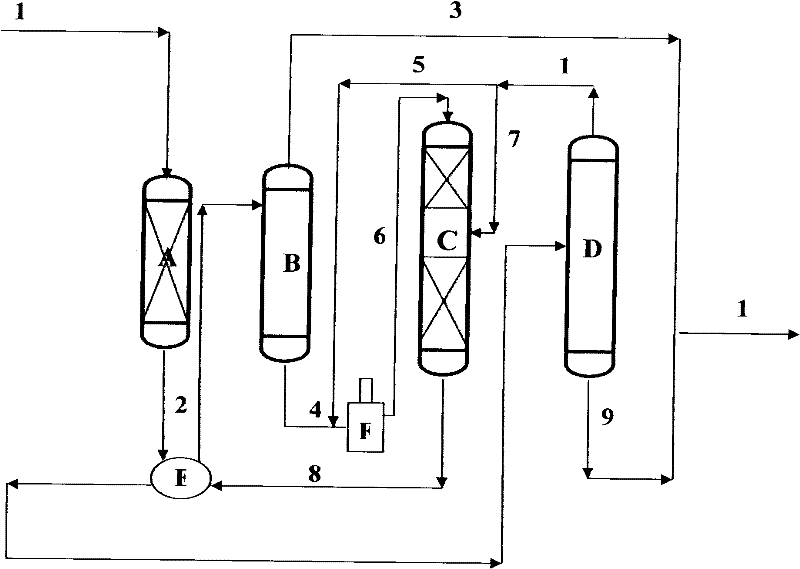

Method used

Image

Examples

Embodiment 1

[0040] Use 1000 grams of aluminum hydroxide powder, add 20 milliliters of nitric acid, 700 milliliters of deionized water and an extrusion aid to mix and roll, extrude into a clover shape, dry at 110°C for 3 hours, and roast at 550°C for 3 hours to obtain an alumina carrier.

[0041] Mix 30 grams of copper nitrate, 18 grams of zinc nitrate, 7 grams of ammonium dihydrogen phosphate and 60 milliliters of deionized water, dissolve at 60 ° C for 1 hour to obtain 65 milliliters of Cu-Zn-P co-immersion solution, and 100 grams of oxidized The aluminum carrier was impregnated with the above impregnating solution at room temperature, dried at 120°C for 8 hours, and calcined at 500°C for 8 hours to obtain the pretreatment catalyst FHT1. The physical properties of the FHT1 catalyst are listed in Table 1.

Embodiment 2

[0043] Use 900g of aluminum hydroxide powder, add 18ml of nitric acid, 600ml of deionized water, 450g of silica sol and extrusion aid, mix and roll, extrude into a clover shape, dry at 110°C for 3 hours, and roast at 550°C for 3 hours to obtain the carrier .

[0044] Mix 60 grams of copper nitrate, 45 grams of zinc nitrate, 4.3 grams of diammonium hydrogen phosphate and 60 milliliters of deionized water, dissolve at 60 ° C for 1 hour to obtain 65 milliliters of Cu-Zn-P co-immersion solution, and 100 grams of roasted carrier T-2 was impregnated with the above impregnation solution at room temperature, dried at 120°C for 8 hours, and calcined at 500°C for 8 hours to obtain the pretreatment catalyst FHT2. The physical properties of the FHT2 catalyst are listed in Table 1.

Embodiment 3

[0050] This example shows the desulfurization effect of inferior FCC gasoline.

[0051] (1) Raw oil pretreatment

[0052] The evaluation test was carried out on a fixed-bed reactor device, and 30 ml of the FHT1 catalyst prepared in Example 1 was loaded into the reactor. Pass hydrogen first (hydrogen volume space velocity 3.0h -1 ), the hydrogen pressure is 1.0MPa, and it is raised from room temperature to 260°C within 6 hours, and then reduced at constant temperature for 8 hours.

[0053] After reduction, the temperature is lowered to 220°C, and the FCC gasoline raw material is fed, the hydrogen partial pressure is 1.6MPa, the hydrogen-oil volume ratio is 400:1, and the volume space velocity is 3.0h -1 . After the oil inlet is stable, sample and analyze. Table 3 lists the main properties of the raw material and the product after pretreatment for 5000 hours.

[0054] (2) Cutting of raw oil light distillate and heavy distillate

[0055] The pretreated FCC gasoline is separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com