Method for preparing amorphous crystalline albendazole

A technology of albendazole and crystal form, applied in the field of preparation of amorphous crystal form albendazole, can solve problems such as being unsuitable for industrialized production, difficult to collect amorphous crystal form albendazole, and many residues, etc. Improve bioavailability, simple method, and the effect of improving dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

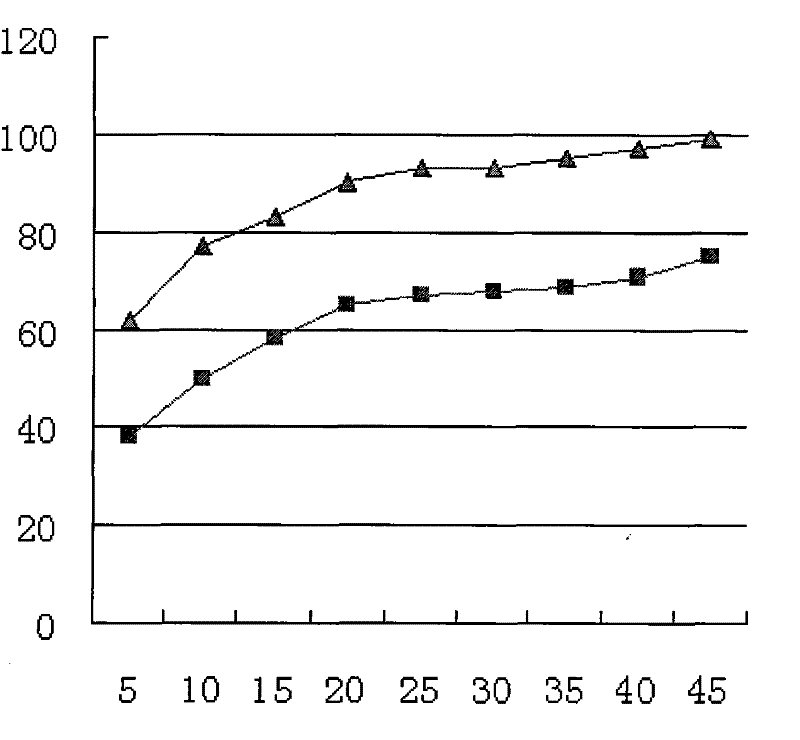

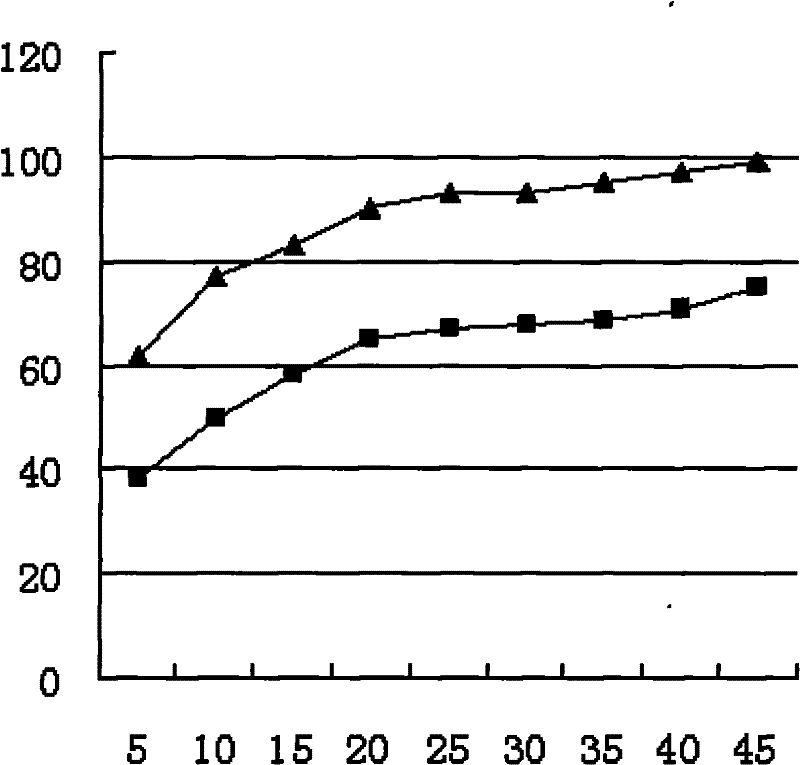

Image

Examples

Embodiment 1

[0022] Put 10g of albendazole in 30ml of 98% formic acid (w / w), heat to 35°C to dissolve it, raise the temperature to 80°C and keep it for 1h, then add 0.01g of activated carbon for decolorization, filter while it is hot, add 10% hydroxide to the filtrate Sodium aqueous solution (w / w) adjusted the pH to 6, filtered with suction, washed with 200g of purified water, sucked dry, and dried to obtain 8.5g of amorphous albendazole with a yield of 85%.

[0023] The resulting product was tested for dissolution under the entry of CP2010 albendazole tablets, and the dissolution amount was 82% of the labeled amount.

Embodiment 2

[0025] Put 10g of albendazole in 50ml of 80% acetic acid (w / w), heat to 40°C to dissolve it, raise the temperature to 85°C and keep it for 1h, then add 0.02g of activated carbon for decolorization, filter while it is hot, and add 20% hydroxide to the filtrate Adjust the pH to 7 with sodium aqueous solution (w / w), filter with suction, wash with 1000 g of purified water, drain and dry to obtain 8.8 g of amorphous albendazole with a yield of 88%.

[0026] The resulting product was tested for dissolution under the entry of CP2010 albendazole tablets, and the dissolution amount was 85% of the labeled amount.

Embodiment 3

[0028] Put 10g of albendazole in 100ml of water, then add 15ml of concentrated hydrochloric acid, heat to 40°C to dissolve it, continue to heat up to 95°C for 1 hour, then add 0.015g of activated carbon for decolorization, filter while it is hot, add 20% hydrogen to the filtrate Adjust the pH to 7 with sodium aqueous solution (w / w), filter with suction, wash with 500 g of purified water, drain and dry to obtain 9.0 g of amorphous albendazole with a yield of 90%.

[0029] The resulting product was tested for dissolution under the entry of CP2010 albendazole tablets, and the dissolution amount was 92% of the labeled amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com