Silica sand composition, formed body and preparation method for formed body

A technology for a composition and a formed body, which is applied in the field of silica sand composition and formed body and the preparation of the formed body, can solve the problem that the strength retention rate needs to be further improved, and achieves easy popularization and application, strong operability, and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

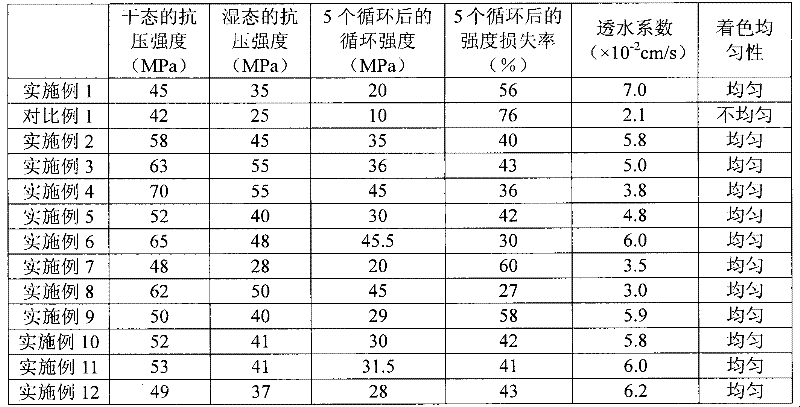

Examples

Embodiment approach

[0038] According to one embodiment of the present invention, the polyurethane adhesive contains isocyanate and polyol. The isocyanate and the polyol can exist separately, and the two are mixed and reacted during use to form a urethane bond, and then form a polyurethane cross-linked structure to realize the function of bonding; it is also possible to use the isocyanate group with End-capping agent (for example: one or more in phenol, cresol, nonylphenol, caprolactam and methyl ethyl ketone) is carried out protection and exists in a closed and moisture-insulated environment with described polyhydric alcohol, during use Under the condition of elevated temperature (for example: 140-180 ℃), the blocking agent is removed, and the isocyanate group is released to react with the hydroxyl group in the polyol to form a urethane bond, and then form a polyurethane cross-linked structure to achieve adhesion. Function.

[0039] In this embodiment, the molar ratio of the isocyanate group in ...

Embodiment 1

[0082] This example is used to illustrate the silica sand composition, permeable brick and preparation method thereof according to the present invention.

[0083] (1) Preparation of silica sand with polymer coating

[0084] With 16g epoxy resin (wherein, 12g is the epoxy resin that the trade mark that Wuxi Resin Factory produces is the epoxy resin of E-51, and epoxy value is 0.473mol / 100g; 4g is that the trade mark purchased from Shanghai Resin Factory Co., Ltd. is ME-2 and Hydrophilic epoxy resin with an epoxy value of 0.376mol / 100g), 15g of titanium dioxide (manufacturer: DuPont, brand: R-902) successively added to a temperature of 120°C and 2kg of silica sand (average particle diameter of 3mm) in a stirred tank, after stirring for 3 minutes, add 4g of grade 593 epoxy resin curing agent (manufacturer: Wuxi Huilong Electronic Materials Co., Ltd.) at 100°C and continue to stir for 5 minutes at 100°C, cool To 25 DEG C, the silica sand with the polymer coating is obtained. By t...

Embodiment 2

[0090] This example is used to illustrate the silica sand composition, permeable brick and preparation method thereof according to the present invention.

[0091] (1) Preparation of silica sand with polymer coating

[0092] Adopt the method identical with embodiment 1 to prepare the silica sand with polymer coating layer, difference is that the consumption of epoxy resin is 80g (wherein, 60g is the epoxy resin that the trade mark that Wuxi Resin Factory produces is E-44, and this The epoxy value of epoxy resin is 0.461mol / 100g; 20g is the hydrophilic epoxy resin of ME-2 and epoxy value 0.376mol / 100g for the trade mark purchased from Shanghai Resin Factory Co., Ltd., epoxy resin curing The consumption of agent is 20g, by weight-gain method, calculate, take the total amount of the silica sand with polymer coating as a benchmark, the content of polymer coating is 5% by weight, and curing degree is 88%.

[0093] (2) Preparation of permeable bricks

[0094] The same method as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com