Porous hollow copper oxide nano fiber and preparation method thereof

A technology of nanofiber and copper oxide, applied in the direction of copper oxide/copper hydroxide, etc., to achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Dissolve copper acetate monohydrate in ethanol and sonicate until completely dissolved. Then add the molecular weight (M r ) is 360,000 polyvinylpyrrolidone and mixed to obtain a spinning solution.

[0034] In the spinning solution, the mass ratio of polyvinylpyrrolidone to copper acetate is 4:1, and the mass percent concentration of the polymer in the spinning solution is 9%.

[0035]2) Electrospin the spinning solution obtained in step 1) under a voltage electrostatic field, then raise the temperature in a muffle furnace to 500°C at a rate of 6.7°C / min, and sinter at 500°C for 2 hours to obtain a porous hollow Copper oxide nanofibers. Among them, the electrospinning conditions are as follows: the voltage is 10KV; the flow rate of the spinning solution is 0.02ml / min; the inner diameter of the spinneret is 0.8mm; the distance between the spinneret and the receiving plate is 13cm.

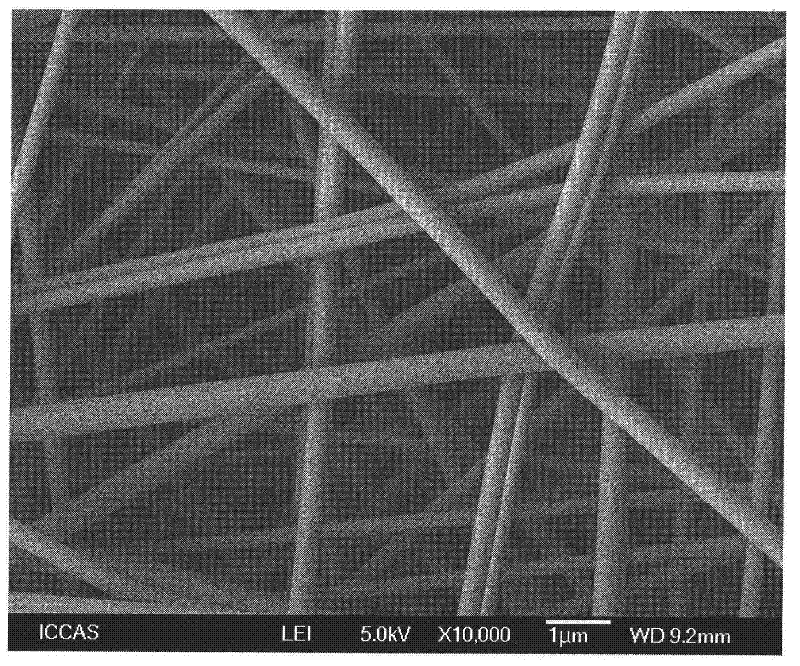

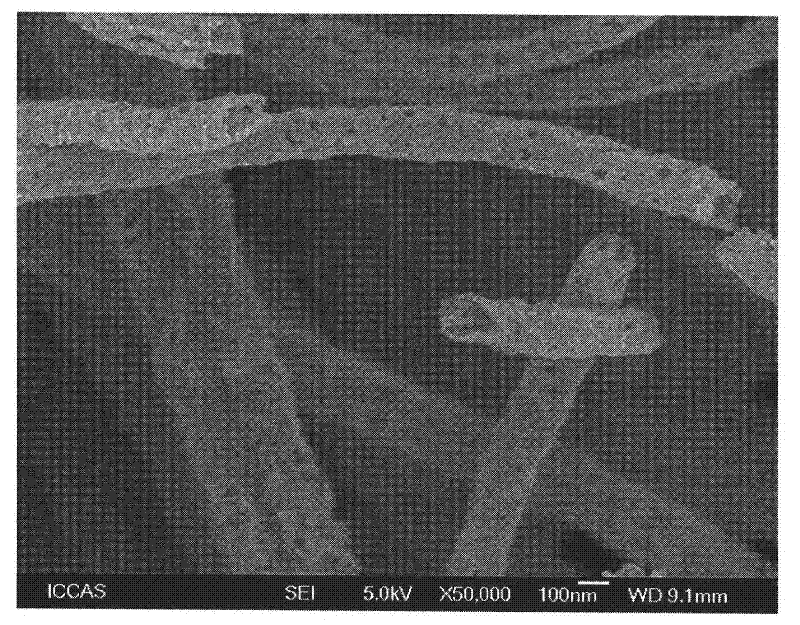

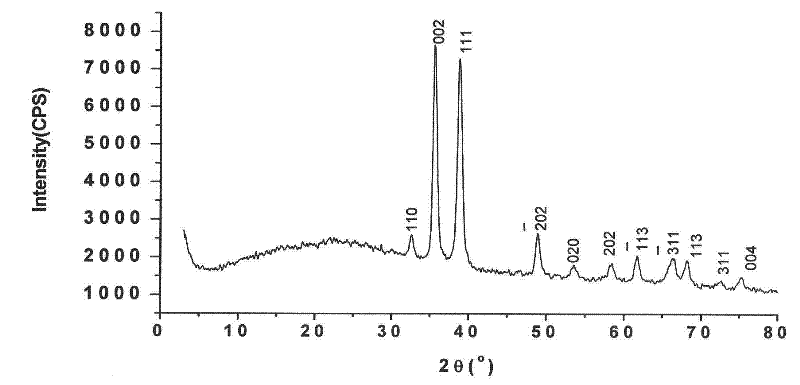

[0036] figure 1 It is a scanning electron micrograph of the nanofiber non-woven fa...

Embodiment 2

[0038] 1) Dissolve anhydrous copper acetate in ethanol, sonicate until completely dissolved, and then add molecular weight (M r ) is 360,000 polyvinylpyrrolidone and mixed to obtain a spinning solution.

[0039] In the spinning solution, the mass ratio of polyvinylpyrrolidone to copper acetate is 2:1, and the mass percent concentration of the polymer in the spinning solution is 15%.

[0040] 2) Electrospinning the spinning solution obtained in step 1) under a voltage electrostatic field, then raising the temperature to 500°C in a muffle furnace at a rate of 10°C / min, and sintering at 500°C for 3 hours to obtain a porous Hollow copper oxide nanofibers. Among them, the electrospinning conditions are as follows: the voltage is 10KV; the flow rate of the spinning solution is 0.05ml / min; the inner diameter of the spinneret is 0.8mm; the distance between the spinneret and the receiving plate is 13cm.

[0041] Figure 5 and Image 6 They are the scanning electron micrographs and ...

Embodiment 3

[0043] 1) Dissolve anhydrous copper acetate in ethanol and sonicate until completely dissolved. Then add the weight average molecular weight (M w ) of 50,000 vinylpyrrolidone-vinyl acetate copolymers were mixed to obtain a spinning solution.

[0044] In the spinning solution, the mass ratio of the copolymer to copper acetate is 8:1, and the mass percent concentration of the copolymer in the spinning solution is 15%.

[0045] 2) Electrospin the spinning solution obtained in step 1) under a voltage electrostatic field, then raise the temperature to 450°C in a muffle furnace at a rate of 5°C / min, and sinter at 450°C for 5 hours to obtain a porous Hollow copper oxide nanofibers. Among them, the electrospinning conditions are as follows: the voltage is 10KV; the flow rate of the spinning solution is 0.02ml / min; the inner diameter of the spinneret is 0.5mm; the distance between the spinneret and the receiving plate is 13cm.

[0046] Figure 7 and Figure 8 They are the scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com