Method for measuring stain on optical lens

An optical lens, lens technology, used in optical testing flaws/defects, scattering characteristics measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

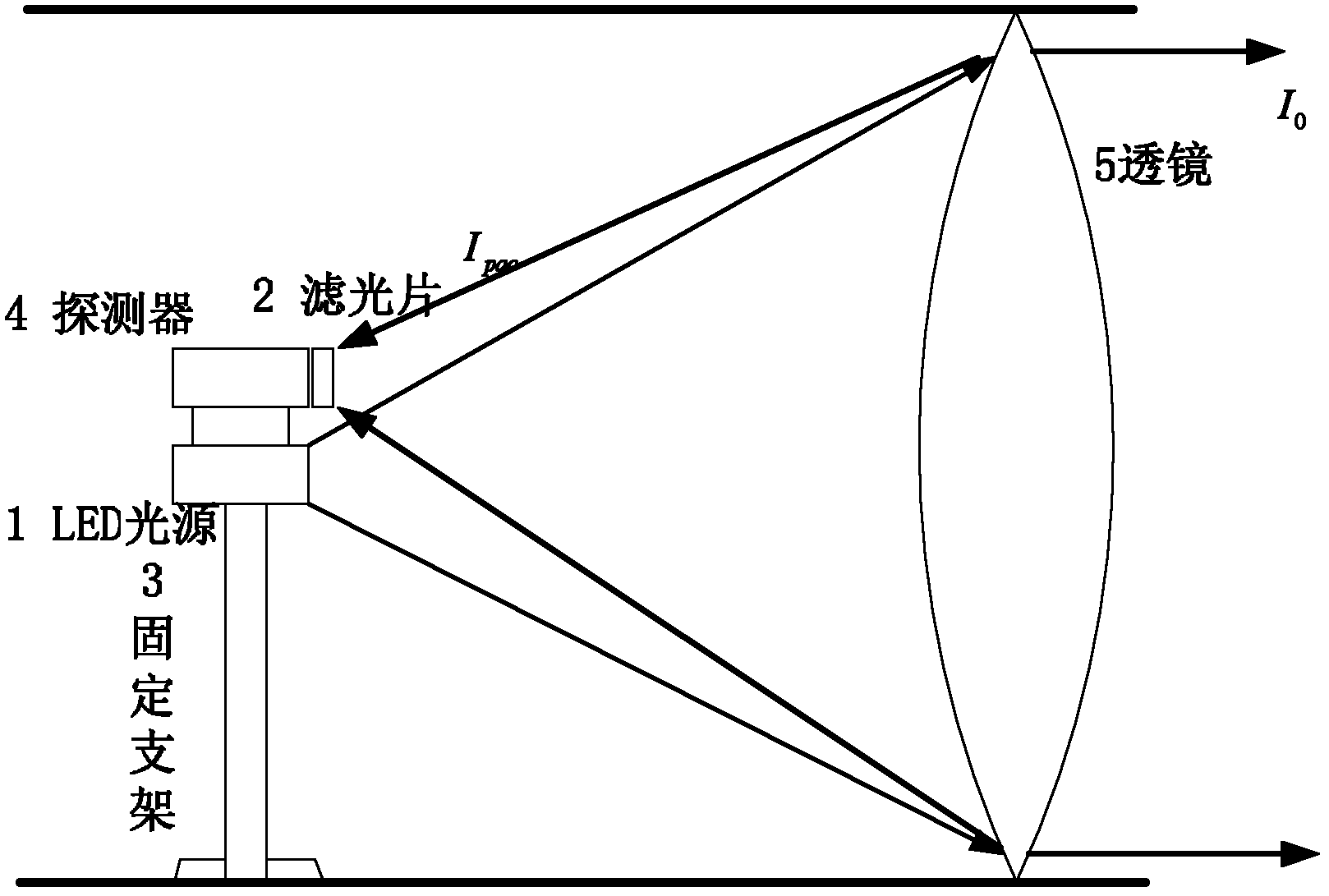

[0059] like figure 1 As shown, the backscattered light signal detection part of the present invention includes: LED light source 1, optical filter 2, fixed bracket 3, detector 4, LED is installed at the center behind the lens inside the instrument, and the direction of light is directed to the lens; the detector adopts The PIN photodiode is fixed at the center of the rear of the measured lens through a fixed bracket, and is located next to the light source, and the detector surface source points to the lens surface. The optical filter is fixed at the front end of the detector area source to filter out the influence of stray light.

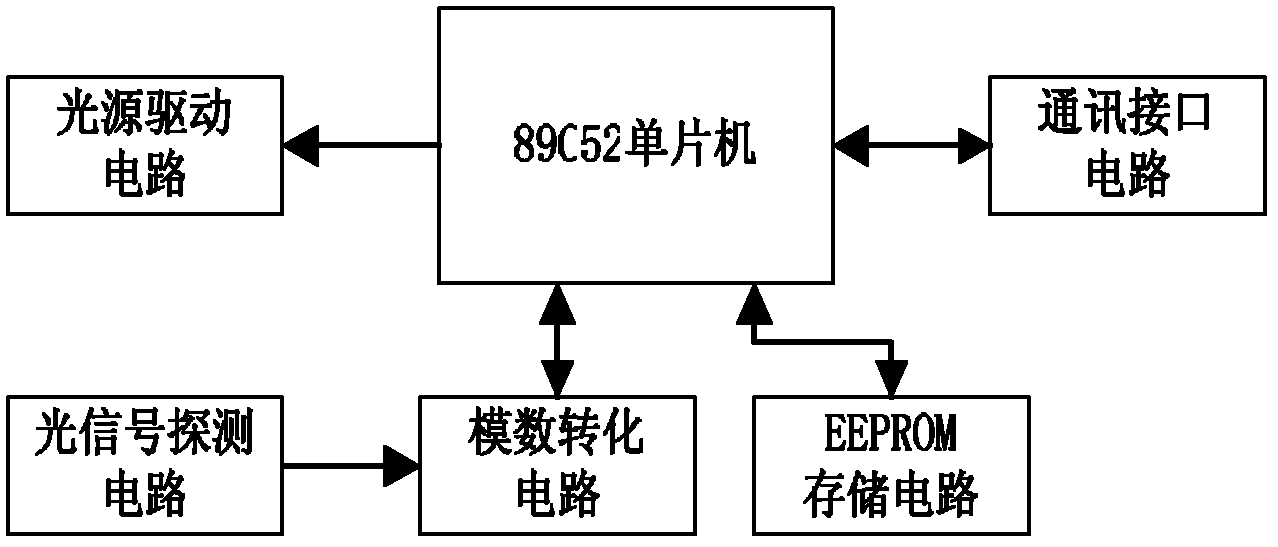

[0060] like image 3 As shown, the measurement control circuit of the present invention comprises: a light source drive circuit, a preamplifier circuit, a filter circuit, a signal demodulation circuit, an analog-to-digital conversion circuit, a single-chip microcomputer, an output interface circuit, and a memory circuit. in:

[0061] The LED lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com