Method for preparing dimethyl adipate by continuous esterification

A technology of dimethyl adipate and adipic acid, which is applied in the field of continuous esterification to prepare dimethyl adipate, can solve the problems of non-continuous pre-esterification, etc., and achieve the goal of increasing temperature, reducing dosage and improving conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

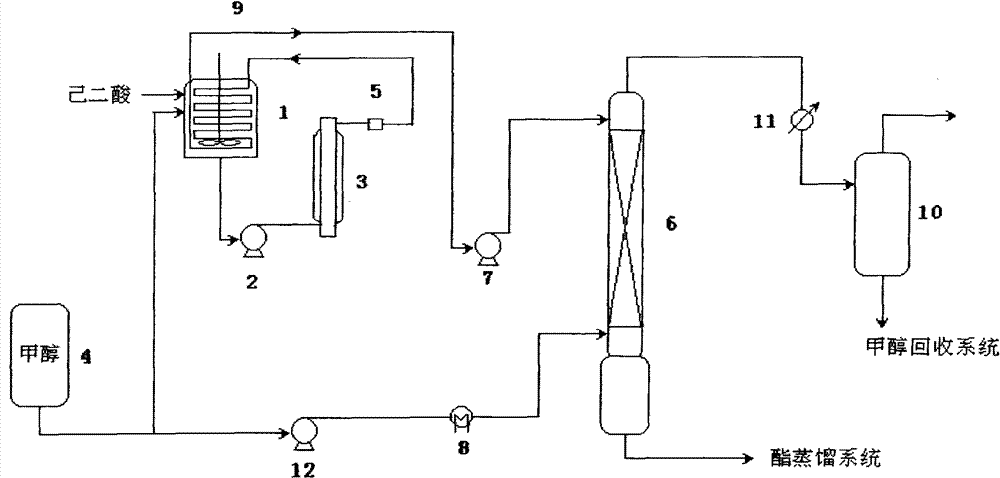

Method used

Image

Examples

Embodiment 1

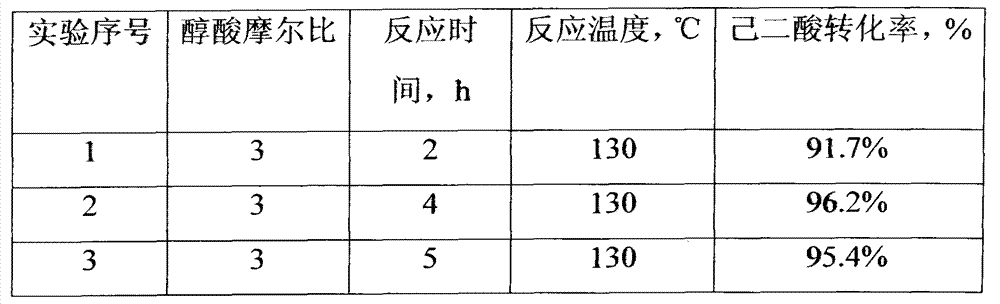

[0026] Pre-esterification experiment

[0027] Mix methanol and adipic acid at an alcohol / acid molar ratio of 3 to 5, and pass through a tubular reactor with a tube length of 5m, an inner diameter of 1cm, and a Statik mixer with 180° twisted blades staggered by 90°. Under the condition of no catalyst, Adipic acid and methanol undergo a pre-esterification reaction, and the experimental results are shown in Table 1 (the conversion rate of adipic acid is calculated according to the results of liquid chromatography analysis).

[0028] Table 1 embodiment 1 pre-esterification reaction result

[0029]

Embodiment 2

[0030] Embodiment 2 pre-esterification test

[0031] Mix methanol and adipic acid at an alcohol / acid molar ratio of 3 to 5, and pass through a tubular reactor with a tube length of 1m, an inner diameter of 1cm, and a Statik mixer with 180° twisted blades staggered by 90°. The reaction time is 2h. Under the condition of no catalyst, adipic acid and methanol undergo a pre-esterification reaction, and the experimental results are shown in Table 2 (the conversion rate of adipic acid is calculated according to the results of liquid chromatography analysis).

[0032] Table 2 embodiment 2 pre-esterification reaction result

[0033] Experiment number

Embodiment 3

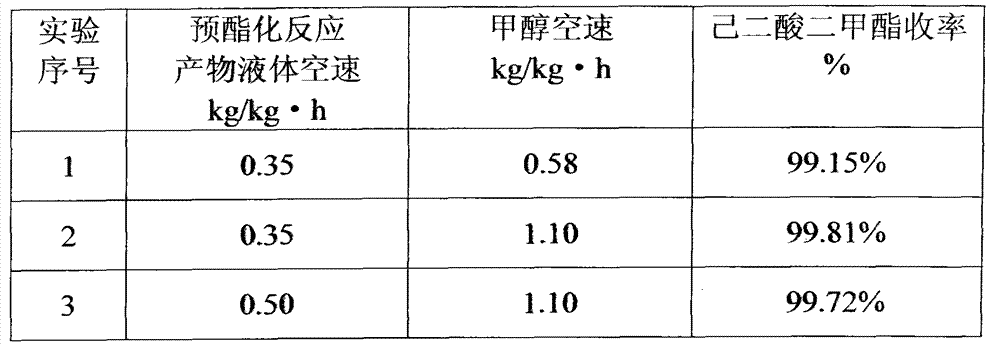

[0036] Esterification experimental results under different space velocities of embodiment 3

[0037] The mixed material after the pre-esterification reaction in Example 1 was used to carry out continuous esterification experiments. The DNW-II resin produced by Dandong Mingzhu Special Resin Co., Ltd. was used as the catalyst, and the catalytic rectification reaction was adopted, and 10 blocks were set in the catalytic rectification tower. Trays, the resin catalyst is evenly distributed on each tray. The operating pressure is normal pressure, the temperature at the bottom of the tower is 120°C, and the temperature at the top of the tower is 95°C. The reaction results under different conditions are shown in Table 3.

[0038] Table 3 catalytic rectification esterification reaction conditions and results

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com