Environment-induced material

An environment and raw material technology, applied in the direction of animal repellent, biological sludge treatment, botanical equipment and methods, etc., to achieve the effect of reducing the breeding of flies and mosquitoes, inhibiting growth, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

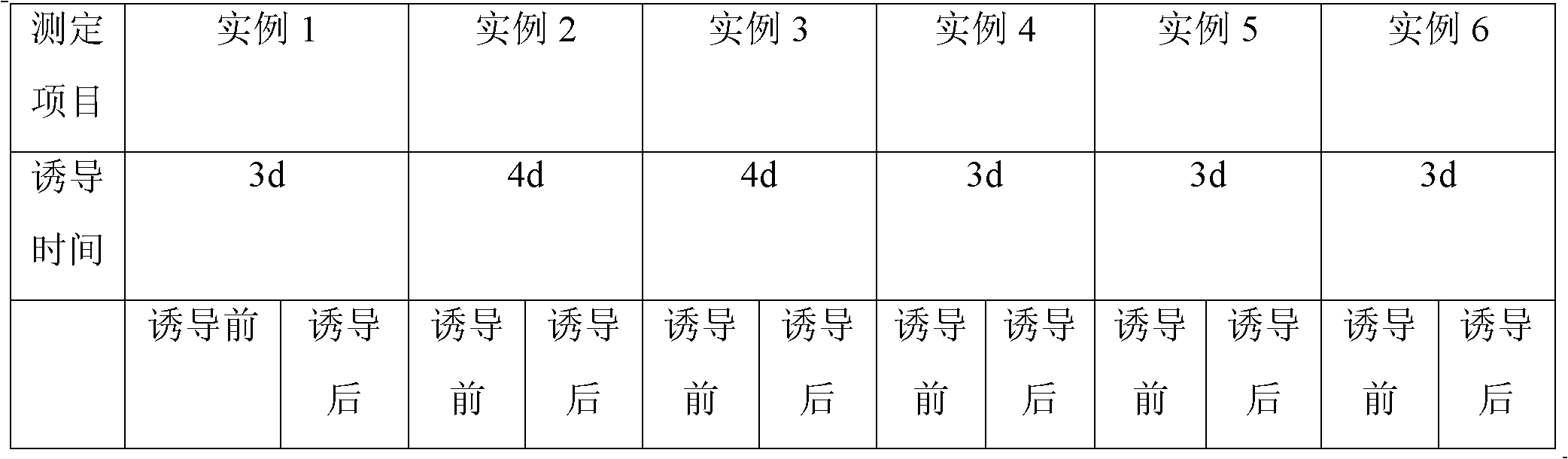

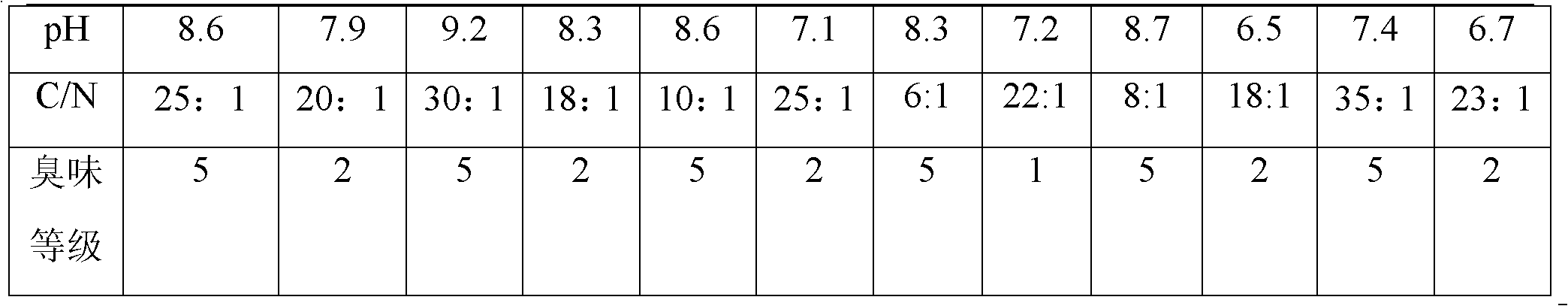

Embodiment 1

[0027] Example 1: 500kg of human and animal manure, 2.5kg of environmental induction materials

[0028] 1. Raw materials: 0.2 parts of citric acid, 0.2 parts of tartaric acid, 2.5 parts of humic acid, 0.5 parts of sulfamic acid, 0.05 parts of magnesium sulfate, 0.05 parts of zinc sulfate, 0.2 parts of magnesium silicate, 0.01 parts of methyl salicylate, 0.5 parts of bentonite parts, 0.04 parts of zinc oxide, 3 parts of attapulgite, 2.5 parts of activated carbon, and 0.05 parts of PAM.

[0029] 2. Implementation method: After mixing the raw materials, sprinkle them evenly in human and livestock manure, stir well, and pile them up at 25°C for 3 days under normal pressure.

Embodiment 2

[0030] Example 2: 800kg landfill waste, 8kg environmental induction material

[0031] 1. Raw materials: 1 part of potassium permanganate, 0.5 parts of magnesium sulfate, 1.5 parts of magnesium silicate, 0.05 parts of nano-silicon oxide, 0.5 parts of calcium oxide, 0.5 parts of zeolite, 0.5 parts of borax, 0.5 parts of zinc oxide, 3 parts of sodium humate parts, attapulgite 2 parts, PAM 0.05 parts.

[0032] 2. Implementation method: mix the raw materials and dilute them with water according to the mass ratio of 1:10, spray on the surface of the garbage layer by layer, that is, spray a layer of diluent and cover a layer of garbage, the outermost layer is covered with straw mats, Warm stack at 35°C for 4 days.

Embodiment 3

[0033] Example 3: 500kg of meat processing waste, 5kg of environmental induction materials

[0034] 1. Raw materials: 0.5 parts of hydrogen peroxide, 0.5 parts of ferric chloride, 1 part of ferrous sulfate, 2.5 parts of sodium humate, 0.1 parts of nano silicon oxide, 0.5 parts of calcium oxide, 0.05 parts of zinc oxide, 0.3 parts of zeolite, 2 parts of activated carbon , attapulgite 2.5 parts, PAM 0.05 parts.

[0035] 2. Implementation method: mix each raw material and dilute it with water according to the mass ratio of 1:20, and spray it on the surface of meat processing waste layer by layer, that is, spray a layer of diluent and cover a layer of waste, the outermost layer is covered with straw mats Covered and stacked at 35°C for 4 days under normal pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com