Method for reducing CO2 emission and producing microalgae lipid by using microalgae

A technology for the production of microalgae and CO2, applied in the direction of fat production, separation methods, fat oil/fat production, etc., can solve the problems of pollution in the microalgae culture system, achieve the effects of reducing pollution rate, increasing contact area, and increasing biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

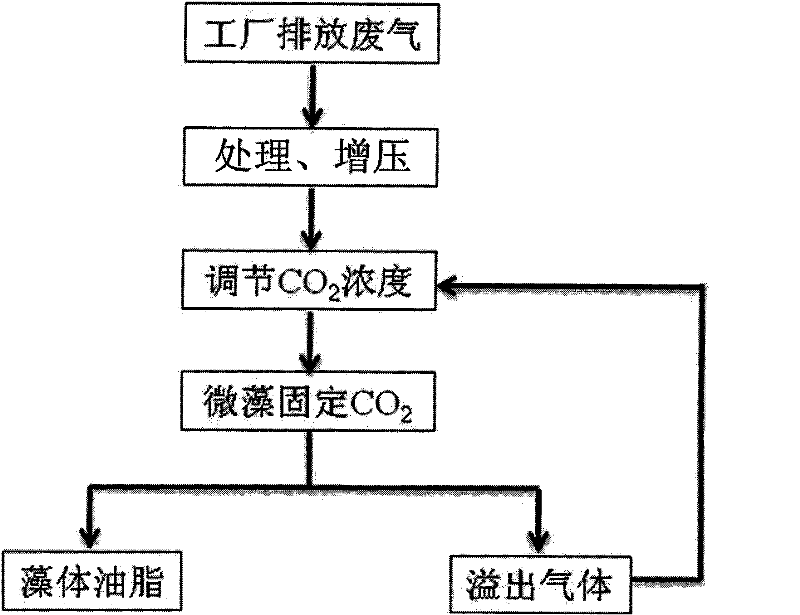

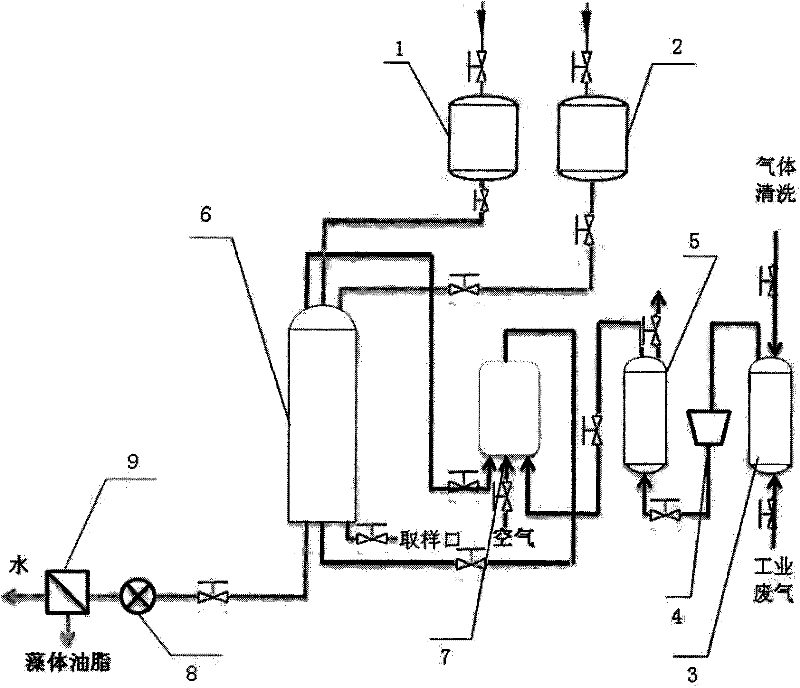

[0028] Use of microalgae to reduce CO as described in this example 2 The method for discharging and producing microalgae oil, its technological process is as follows figure 1 As shown, the treatment and pressurization of exhaust gas from the factory, and the adjustment of CO in exhaust gas 2 content and CO fixation by microalgae 2 . equipment used such as figure 2 As shown, it consists of seed tank 1, medium storage tank 2, scrubber 3, air compressor 4, cooler 5, sealed photobioreactor 6, gas filter regulator 7, flow meter 8 and algae separator 9 composition. The structure of the sealed photobioreactor 6 is as follows: image 3 , Figure 4 As shown, comprising cylinder 10, described cylinder 10 is transparent cylinder, and its top wall is provided with air outlet 11, inoculation port 12 and feeding port 13, and its bottom wall is provided with liquid outlet 15, sampling port 15 and The air inlet 17 is provided with a microbubble generator 14 at the bottom thereof.

Embodiment 2

[0030] In this example, Dunaliella salina is used as algae species to treat industrial waste gas from power plants, and the equipment described in Example 1 is used.

[0031] Dunaliella salina medium formula:

[0032] Liquid A: NaCl 5-10g

[0033] FeC 6 h 5 o 7 0.001g

[0034] Seawater 500ml

[0035] Sea mud extract 20-30ml

[0036] Liquid B: NaNO 3 0.5g

[0037] K 2 HPO 4 0.05g

[0038] Seawater 500ml

[0039] When in use, the volume ratio of medium A and medium B is 1:1, and the medium composed of Dunaliella salina seed liquid A and medium B is mixed. If you add 2-3‰ of urine, the effect will be better. The volume ratio of the seed liquid to the medium is 1:4-1:9 and inoculated in the photobioreactor, the liquid filling volume is 90%, and the density of the inoculation algae is controlled at 2×10 5 cells / ml, the best inoculation time is between 8 and 10 in the morning. CO emissions from plants for dedusting, press...

Embodiment 3

[0042] In this embodiment, chlorella is used as an algal species to treat industrial waste gas from a power plant, and the equipment described in Embodiment 1 is used.

[0043] Chlorella commonly used medium formula:

[0044] NH 4 NO 3 50-100μg

[0045] K 2 HPO 4 5μg

[0046] FeC 6 h 5 o 7 0.1-0.5mg

[0047] Seawater 1000ml

[0048] When in use, the ratio of the seed liquid to the culture medium is 1: 4, and it is inoculated in the sealed photobioreactor 6, and the liquid filling volume is 90%, and the density of the inoculated algae is controlled at 2 × 10 5 cells / ml, the best inoculation time is between 8 and 10 in the morning. CO emissions from plants for dedusting, pressurization and conditioning 2 , pass into the sealed photobioreactor 6 with 800ml / min through microbubble generator 14, make CO 2 The gas is in full contact with the algae species, and the agitation of the culture solution is realized to avoid aggregation and adhering to the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com