Membrane covering aerobic fermentation circulating device and circulating method

An aerobic fermentation and circulation device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve deodorization, emission reduction effect limitations, uneven temperature and humidity distribution, fermentation Insufficient and other problems, to achieve the effect of reducing greenhouse gas emissions, avoiding excessive consumption, and good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

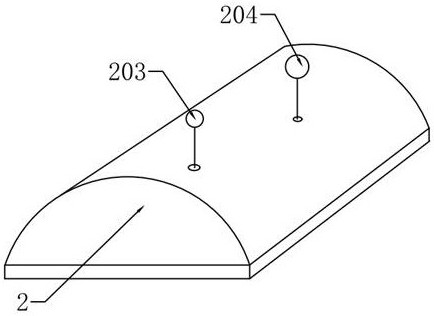

[0060] A film-covered aerobic fermentation cycle device, the fan 1 is only connected to the first fermentation chamber 2, such as figure 1 , figure 2 , image 3 shown.

[0061] The first fermentation chamber 2 adopts film-covered fermentation, which uses a waterproof and moisture-permeable membrane. Film-covered fermentation does not require complicated structures (such as reaction kettles, fermentation tanks, or civil fermentation rooms, etc.), and rainwater cannot enter the membrane when used in the open air , the covered waterproof and moisture-permeable membrane can effectively block odorous macromolecules, pathogenic bacteria, dust, etc., and allow water vapor smaller than the nanoscale micropore diameter of the membrane to pass through. Under the action of slight positive pressure, the liquid phase water in the compost is ordered Converted into gas phase water, discharged out of the membrane to dry the compost product.

[0062] The air inlet of the first fermentation...

Embodiment 2

[0075] A membrane-covered aerobic fermentation cycle device, such as Figure 4 shown.

[0076] Its technical scheme is basically the same as that of Example 1, except that a second fermentation chamber 3 is added to the side of the first fermentation chamber 2. The air inlet of the second fermentation bin 3 is connected with the fan 1 through the second air supply pipe 104 , and the air outlet of the second fermentation bin 3 is connected with the fan 1 through the exhaust pipe 102 . A second air outlet pipe 302 is arranged inside the second fermentation bin 3 , and the second air outlet pipe 302 passes through the air outlet of the second fermentation bin 3 and is connected to the exhaust pipe 102 . The inside of the second fermentation bin 3 is provided with a second ventilation pipe 301 , the second ventilation pipe 301 is connected to the second air supply pipe 104 , and the structure of the second ventilation pipe 301 is the same as that of the first ventilation pipe 201...

Embodiment 3

[0090] A membrane-covered aerobic fermentation cycle device, such as Figure 5 shown.

[0091] The circulation device of this embodiment is basically the same as that of Embodiment 2, except that a third fermentation chamber 4 is added after the second fermentation chamber 3, and the air inlet of the third fermentation chamber 4 passes through the third air supply pipe 107 is connected with the blower fan 1, and the air outlet of the third fermentation bin 4 is connected with the blower blower 1 through the exhaust pipe 102. A third air outlet pipe 402 is arranged inside the third fermentation chamber 4 , and the third air outlet pipe 402 passes through the air outlet of the third fermentation chamber 4 and is connected to the exhaust pipe 102 . The third fermentation bin 4 is provided with a third ventilation pipe 401 inside, and the third ventilation pipe 401 is connected with the third air supply pipe 107 , and the structure of the third ventilation pipe 401 is the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com