Amlodipine benazepril pharmaceutical composition

A technology of amlodipine and benazepril hydrochloride, applied in drug combinations, active ingredients of heterocyclic compounds, pharmaceutical formulations, etc., can solve the problems of enhanced hydrophobicity of tablets, large number of machines, and influence of water infiltration, etc., to achieve improved Dissolution and disintegration, simple preparation process, and the effect of improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

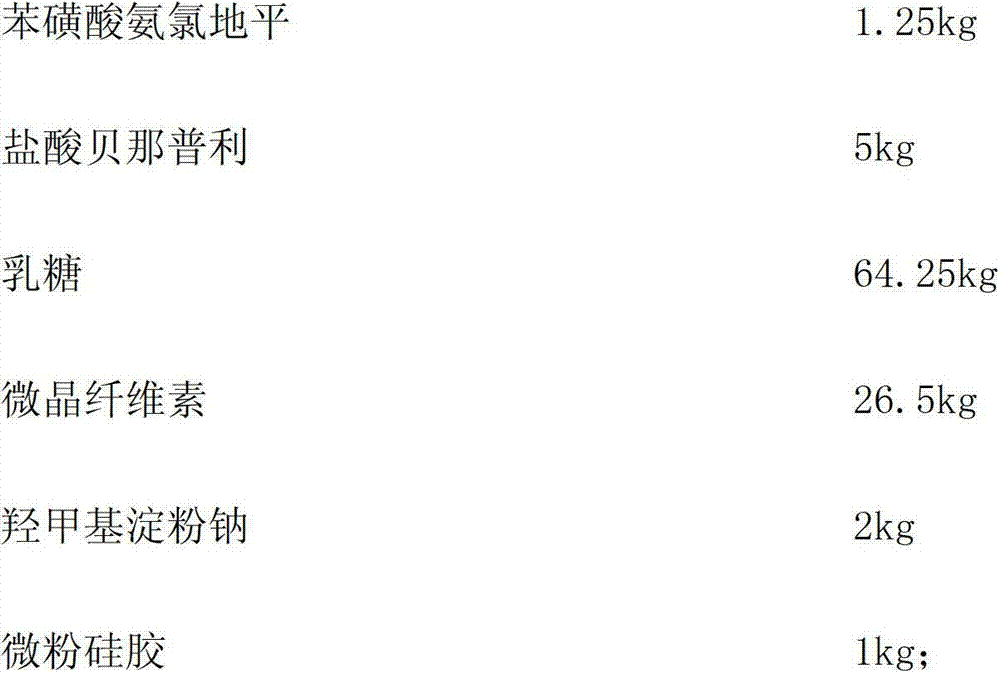

[0033] The amount of each raw material component prepared by the present embodiment for amlodipine benazepril tablet is:

[0034]

[0035] The concrete steps of present embodiment preparation amlodipine benazepril tablet are as follows:

[0036] a. Pulverize and sieve amlodipine besylate and benazepril hydrochloride, weigh amlodipine besylate, benazepril hydrochloride, micropowder silica gel, lactose, microcrystalline cellulose and hydroxymethyl Sodium starch;

[0037] b. In the weighed lactose, take 20% of the lactose and amlodipine besylate and mix them evenly in a high-efficiency mixer. The speed of the high-efficiency mixer is 12r / min, mix for 5min, and take a sample to detect the uniformity of the content , the content uniformity reaches the standard, and the mixture I is obtained after the mixing is completed;

[0038] c. Add the remaining lactose and benazepril hydrochloride to the mixture I in turn, mix well, the speed of the high-efficiency mixer is 12r / min, mix ...

Embodiment 2

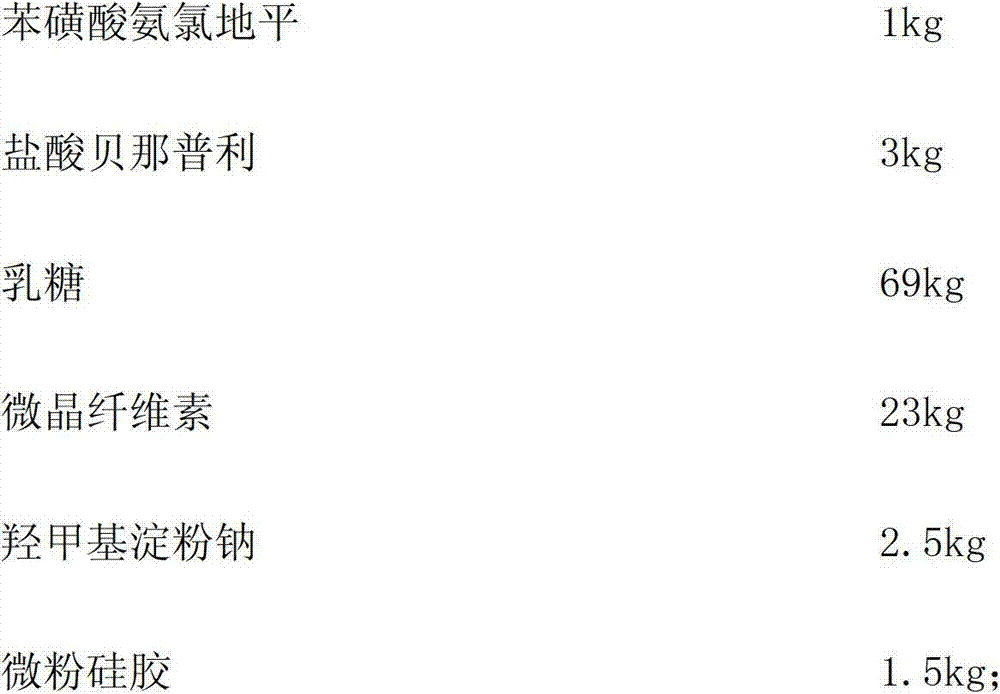

[0043] The amount of each raw material component prepared by the present embodiment for amlodipine benazepril tablet is:

[0044]

[0045] The specific steps for preparing amlodipine and benazepril tablets in this embodiment are the same as in embodiment 1.

Embodiment 3

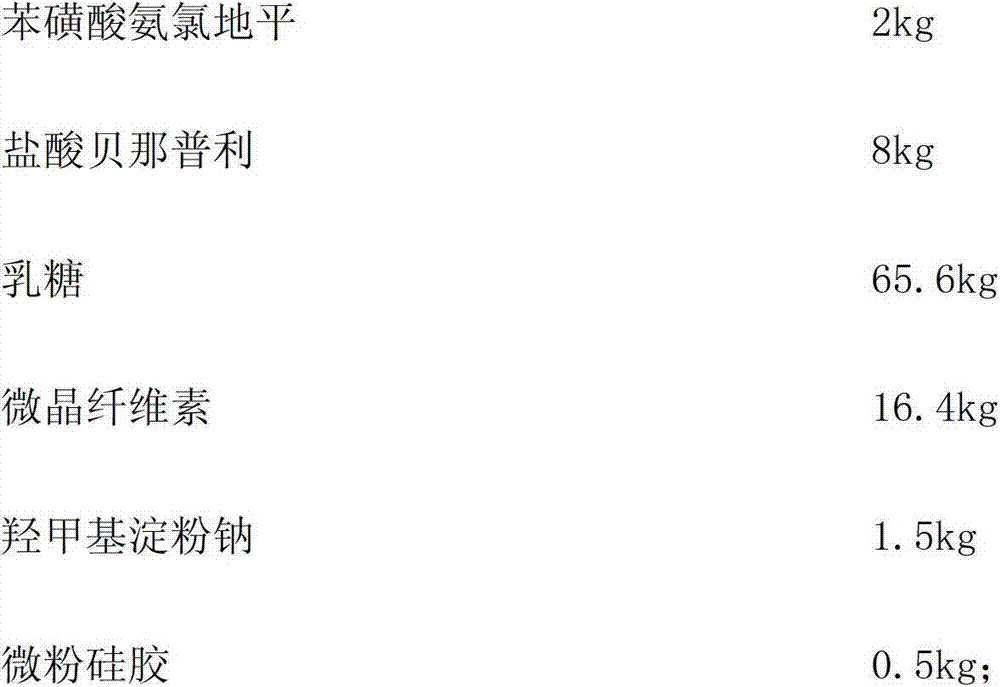

[0047] The amount of each raw material component prepared by the present embodiment for amlodipine benazepril tablet is:

[0048]

[0049] The specific steps for preparing amlodipine and benazepril tablets in this embodiment are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com