Digital-type hysteresis control current source

A technology of hysteresis control and current source, applied in the field of digital hysteresis control current source, can solve the problems of difficulty in product upgrading, poor control system consistency, system reliability decline, etc., to achieve strong anti-interference ability, easy to standardize, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with accompanying drawing.

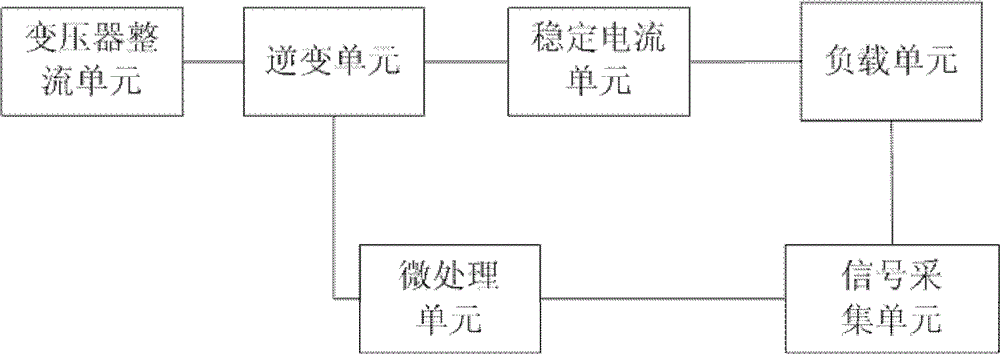

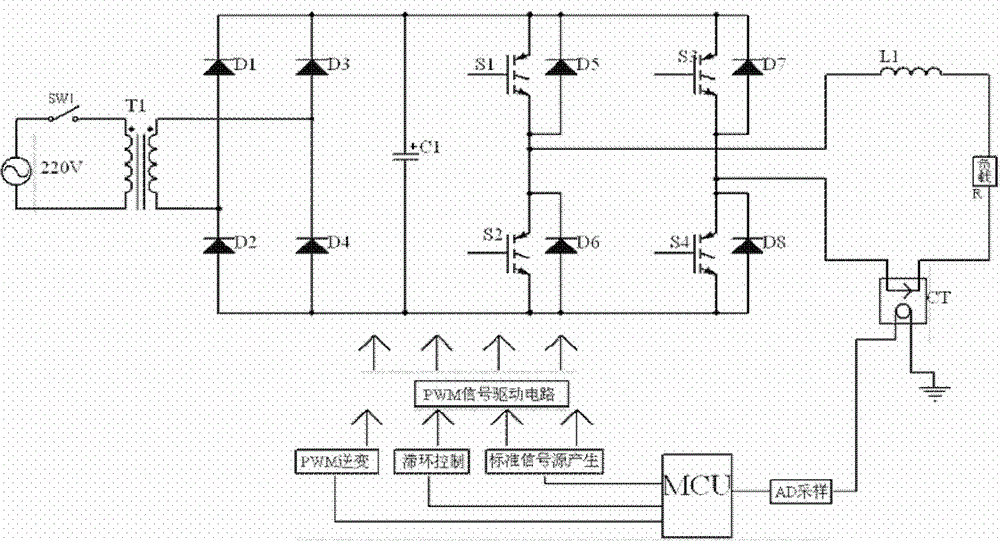

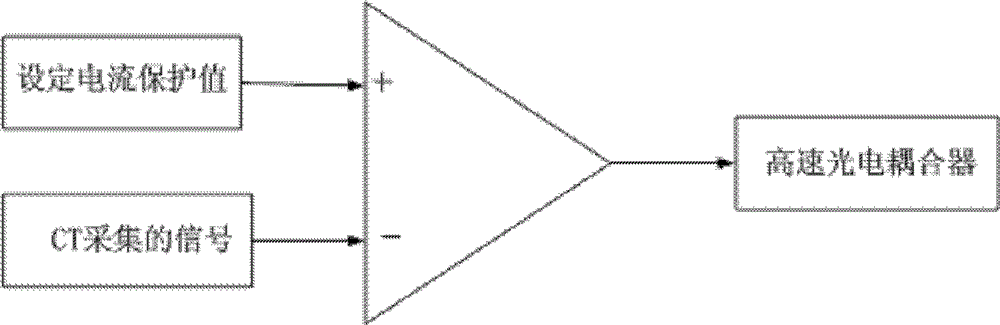

[0031] Such as figure 1 and figure 2 As shown, a digital hysteresis control current source, the current source includes a transformer rectifier unit, a stable current unit and a load unit; the transformer rectifier unit includes a transformer and an H-type full-bridge uncontrolled rectifier; the The transformer and rectifier unit converts the mains AC voltage into a DC voltage after step-up and rectification, and the inverter unit inputs the DC voltage into the stable current unit and then transmits it to the load unit; the signal acquisition unit collects the The current signal is transformed into a voltage signal, which is amplified and input to the AD conversion unit for processing and input to the micro-processing unit MCU.

[0032] The AD conversion unit adopts the chip AD7663, the chip AD7663 is an analog-to-digital converter with a 16-bit sampling and holding fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com