Bonding alloy wire and production technology thereof

A production process and alloy wire technology, applied in the field of bonding alloy wire and its production process, can solve the problems of high price, affect popularization and application, only fall but not rise, etc., and achieve the effect of convenient and practical production process and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

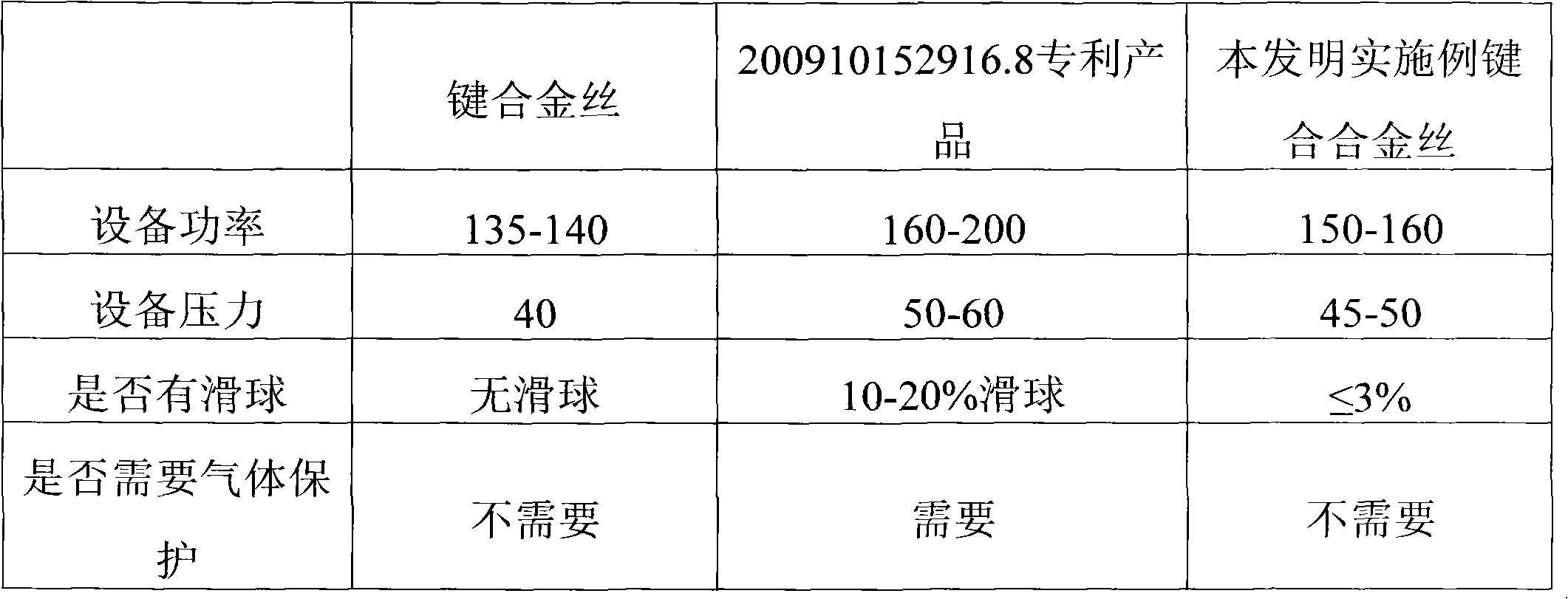

Image

Examples

Embodiment 1

[0034] The bonding alloy wire of the present invention includes a base material and a coating layer plated on the surface of the base material, wherein the base material is a silver material with a total purity ≥ 99.9%, and alloy elements calcium, palladium, and gold are added to the silver material, and the coating layer is gold.

[0035] Indium, nickel, copper, cerium, yttrium, aluminum, and magnesium are also added to the above base material.

[0036] The content of each alloy element calcium, palladium and gold added to the above base material is: 5-100ppm. Ppm refers to the unit of metal content, 1ppm = 0.0001% content, each alloy element is actually added more or less, mainly according to its role in the alloy.

[0037] In the present embodiment, the content of the added alloy elements is as follows, the unit is ppm:

[0038] Calcium = 10

[0039] Palladium = 50

[0040] Gold = 30

[0041] Indium = 30

[0042] Nickel = 10

[0043] Cerium = 30

[0044] The film th...

Embodiment 2

[0072] The difference between the embodiment of the present invention and embodiment 1 is that the following alloy is added to the substrate, and the content of the added alloy elements is as follows, in ppm:

[0073] Calcium = 8

[0074] Palladium = 15

[0075] Gold = 25

[0076] Indium = 10

[0077] Copper = 10

[0078] Yttrium = 20

[0079] Aluminum = 30

[0080] Magnesium = 10

[0081] In this example, the diameter of the substrate is Micron, the coating thickness is 0.10 micron, the diameter of the substrate is Micron, the coating thickness is 0.08 micron.

[0082] The annealing properties are as follows

[0083] A tensile tester is used with a preset length of 100mm and a tensile speed of 12mm / min. Consistent with bonding gold wire.

[0084] Take wire diameter Φ20 microns as an example

[0085]

Embodiment 3

[0087] The difference between the embodiment of the present invention and embodiments 1 and 2 is that the following alloys are added to the substrate, and the content of the added alloy elements is as follows, in ppm:

[0088] Calcium = 40

[0089] Gold = 80

[0090] Indium = 40

[0091] Cerium = 30

[0092] Magnesium = 25

[0093] In this embodiment, the diameter of the substrate is Φ25 microns, and the thickness of the coating film is 0.15 microns. When the diameter of the substrate is Φ23 microns, the thickness of the coating film is 0.14 microns.

[0094] The annealing properties are as follows

[0095] A tensile tester is used with a preset length of 100mm and a tensile speed of 12mm / min. Consistent with bonding gold wire.

[0096] Take wire diameter Φ25 microns as an example

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com