Flexible electro-chromic device

An electrochromic and chromic technology, applied in electrolytic components, instruments, electrolytic processes, etc., can solve problems such as limited applications, achieve uniform electrochromic films, realize large-area electrochromic devices, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

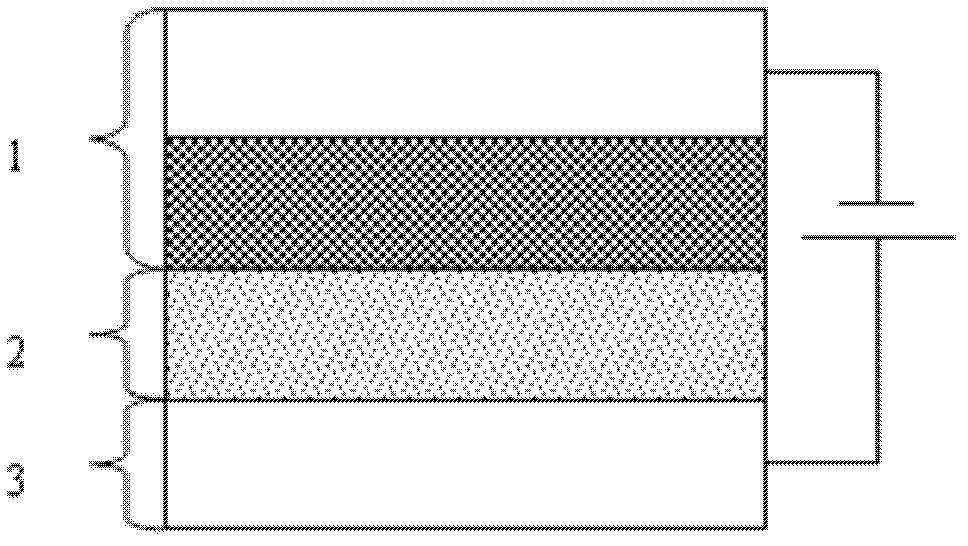

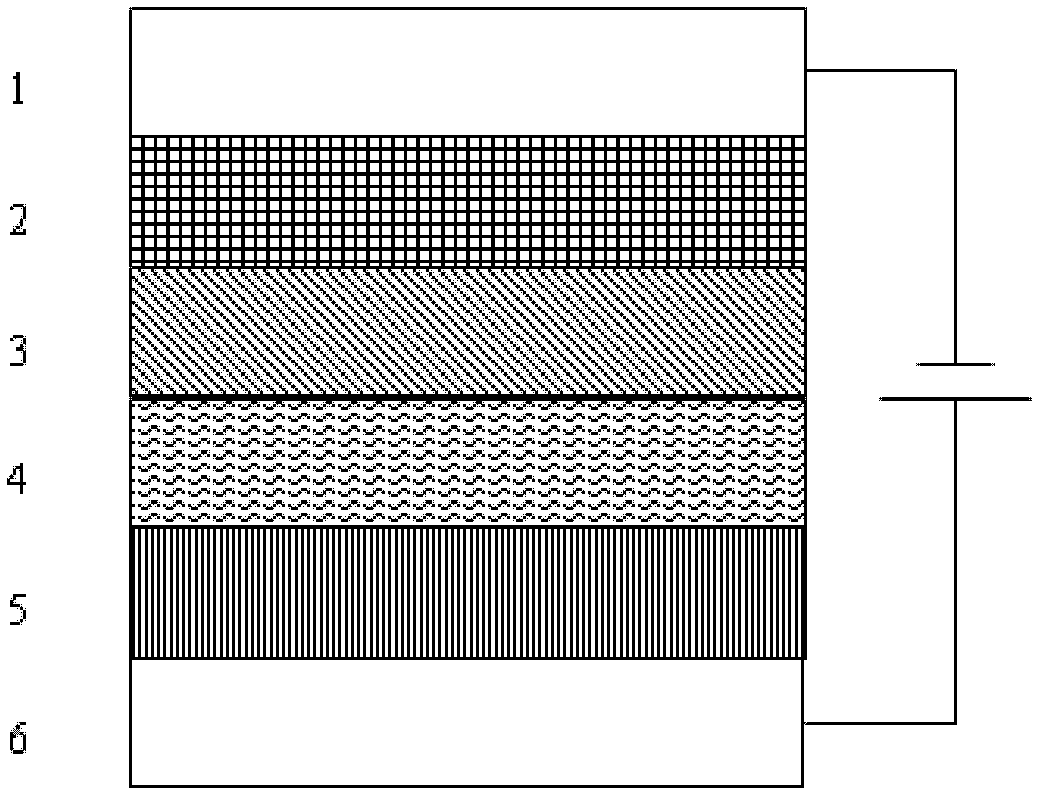

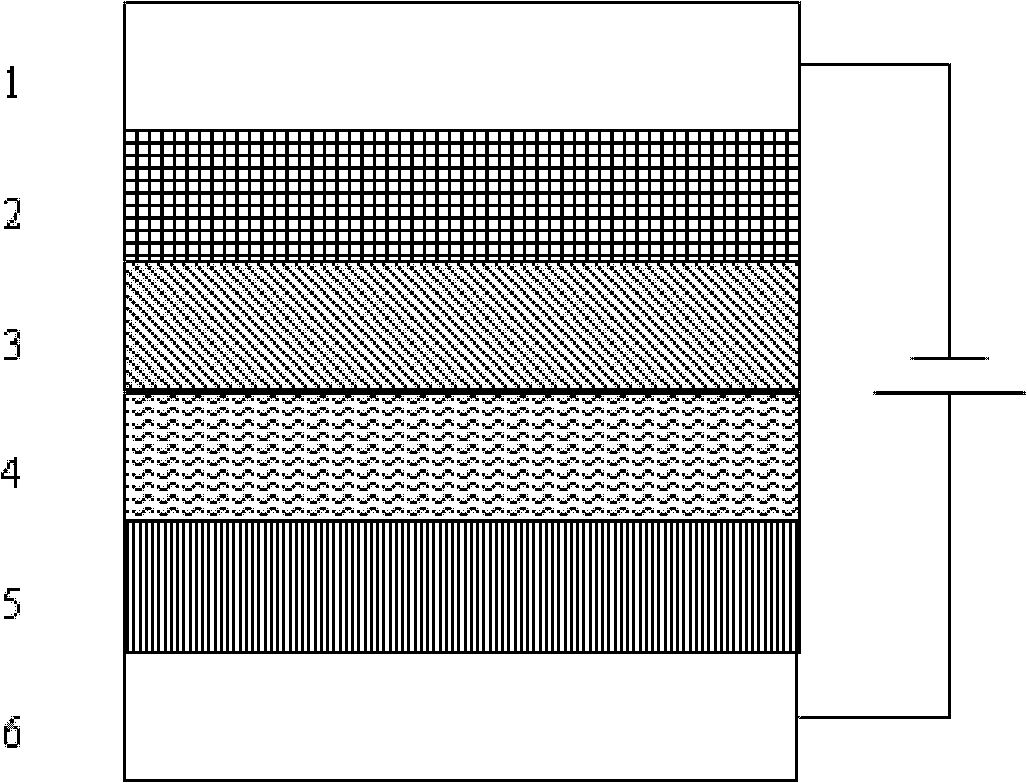

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is the current typical "sandwich" electrochromic device assembly method, including: electrochromic film deposited on the upper electrode, electrolyte layer and lower electrode. The deposition of color-changing film is an important part of the whole device, and currently mainly includes chemical in-situ deposition, electrochemical deposition, spin coating method, pull method, screen printing and magnetron sputtering, etc. The research group has long been committed to figure 1 The structure of the device was explored, and it was found that the adhesion, uniformity, and large area should be considered when depositing a color-changing film on different electrodes. In the electrochromic device provided by the present invention, it is deposited on the flexible gold film by electrochemical method, because the gold film has a porous network...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com