Temperature compensation method of SAW (surface acoustic wave) high-temperature pressure sensor based on vertical-horizontal stress adjustment

A pressure sensor and stress adjustment technology, applied in the field of temperature compensation, can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

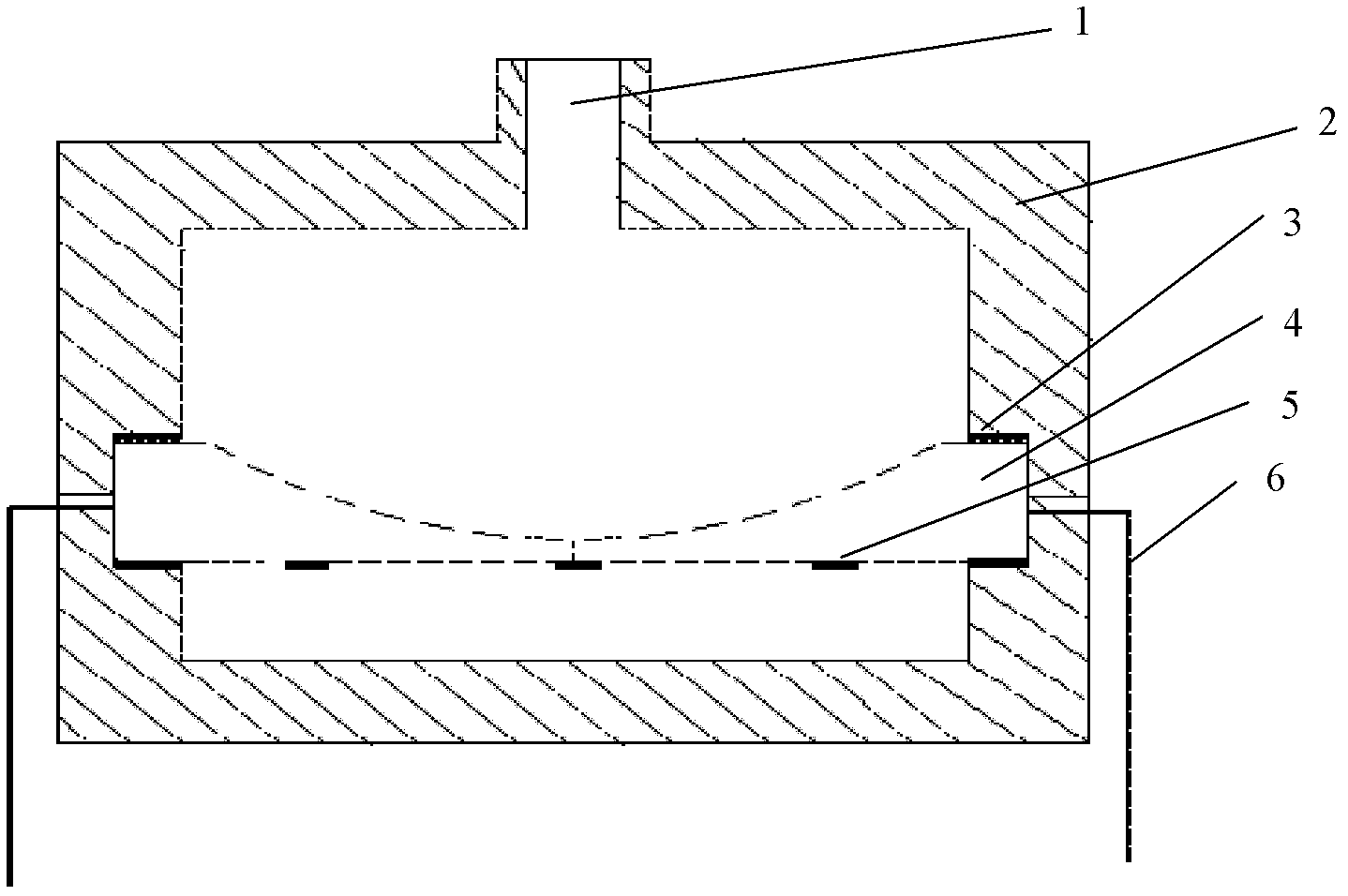

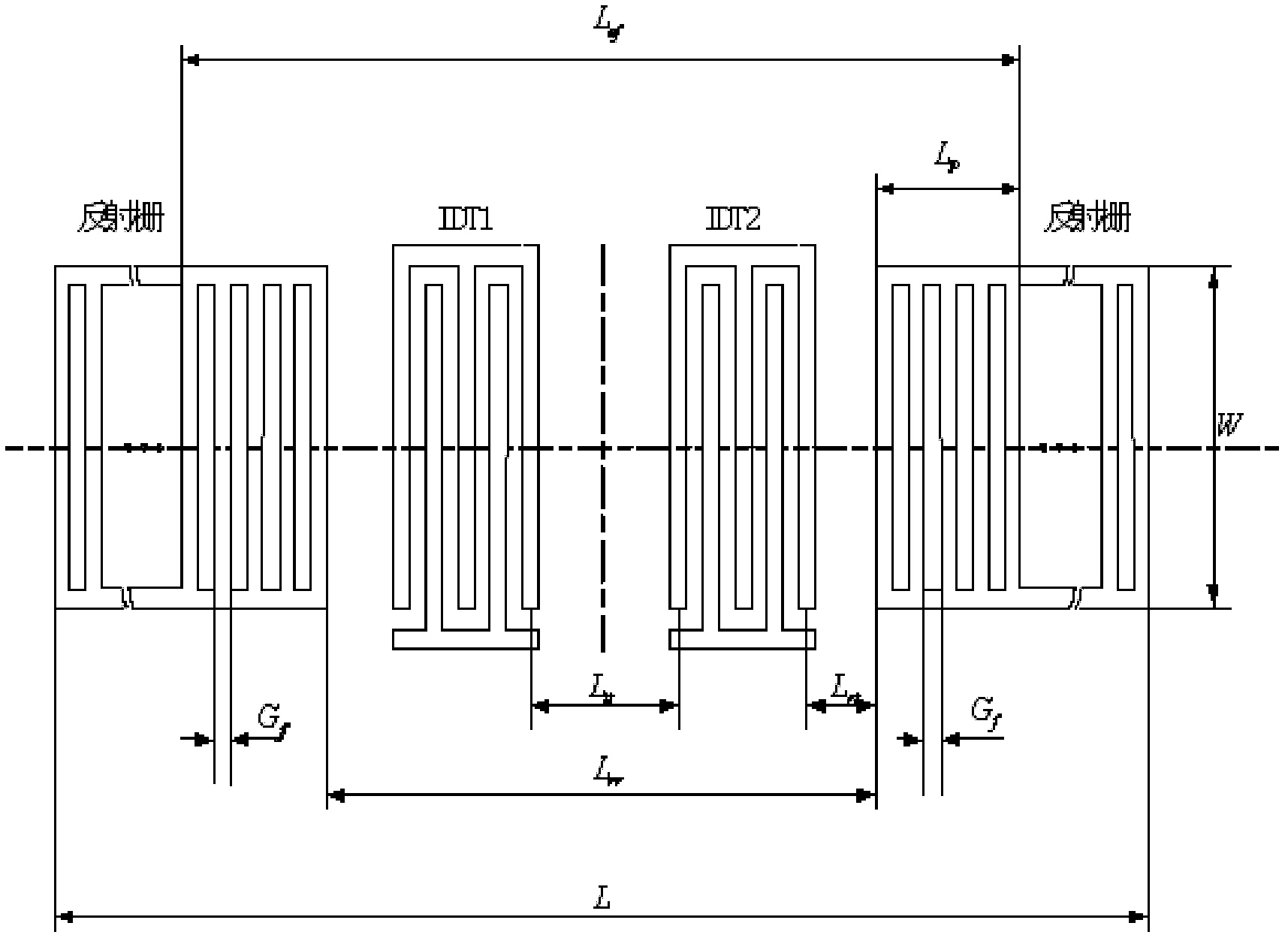

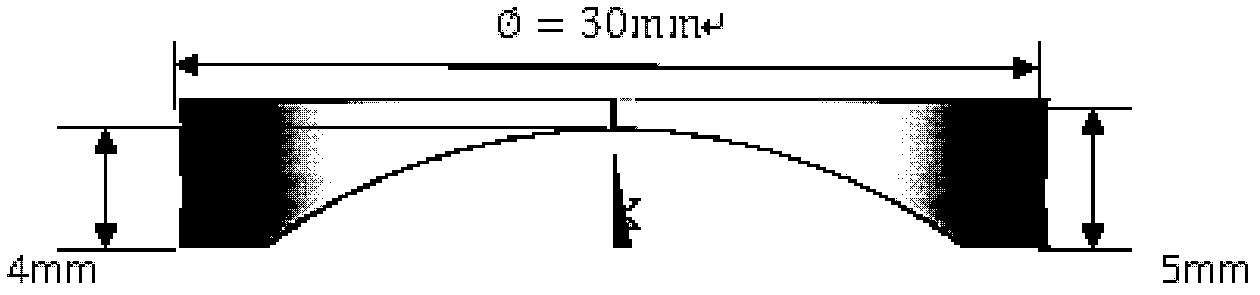

[0038] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and a feasible implementation mode and specific operation process are provided, but the protection scope of the present invention does not Limited to the following examples.

[0039] With the emerging piezoelectric crystal LGS (lanthanum gallium silicate, Langsite (La 3 Ga 5 SiO 14 )) is the sensor substrate material, according to the characteristics of piezoelectric crystal anisotropy, using the method of solving the Christofel equation in the piezoelectric medium, solve the wave velocity, electromechanical coupling coefficient, energy flow angle, anisotropic Surface wave parameters such as anisotropy factor and effective dielectric constant, and then use disturbance theory combined with boundary conditions to calculate frequency temperature coefficient, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com