On-line ultrasound rotational flow descaling device for condenser

A cyclone descaling and condenser technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of slow flow rate, small thermal conductivity of dirt, increase heat transfer thermal resistance, etc., and achieve optimal operation control mode , Make up for the loss of pulse energy and improve the heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below through specific examples, but the present invention is not limited to the following examples.

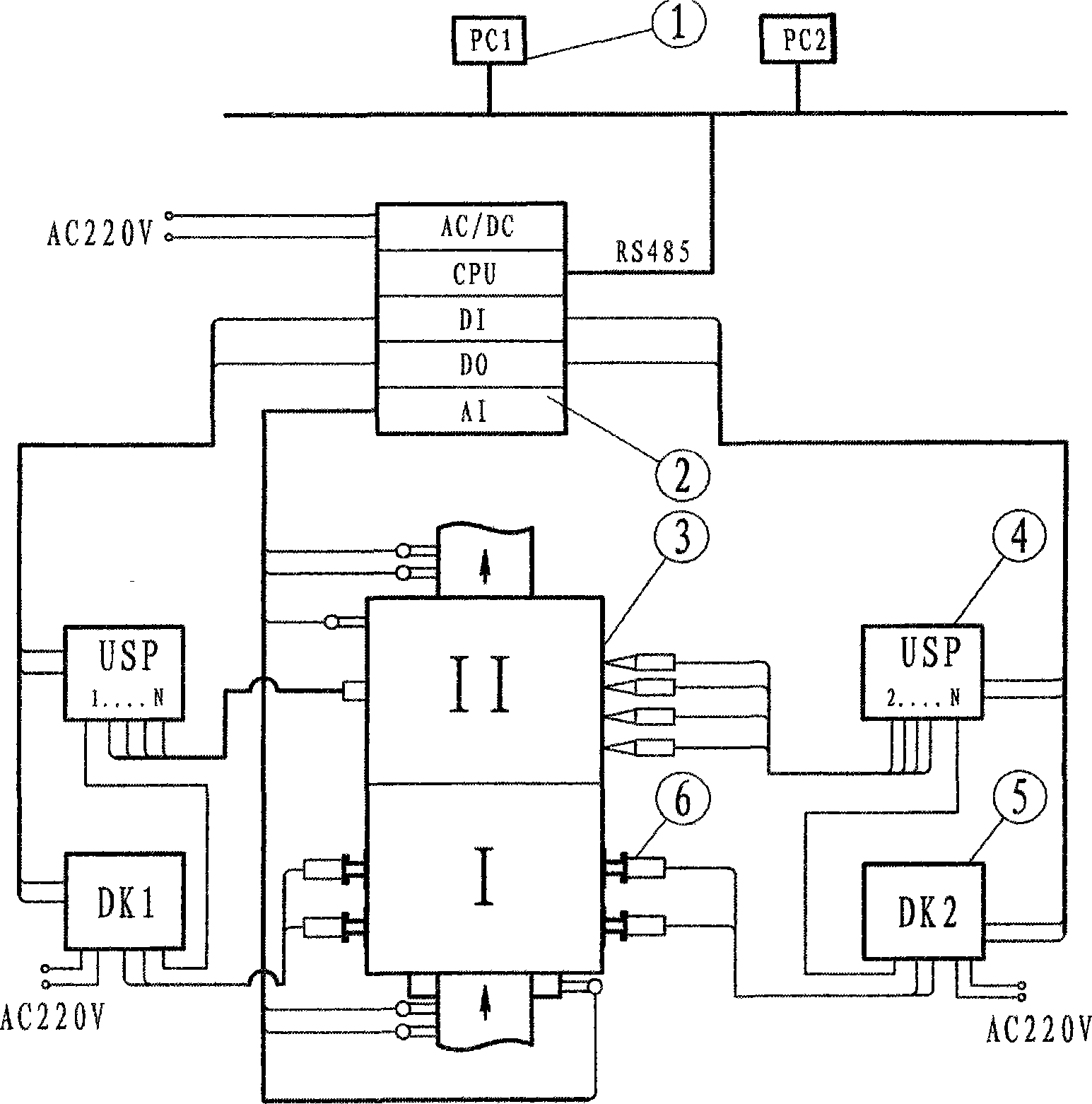

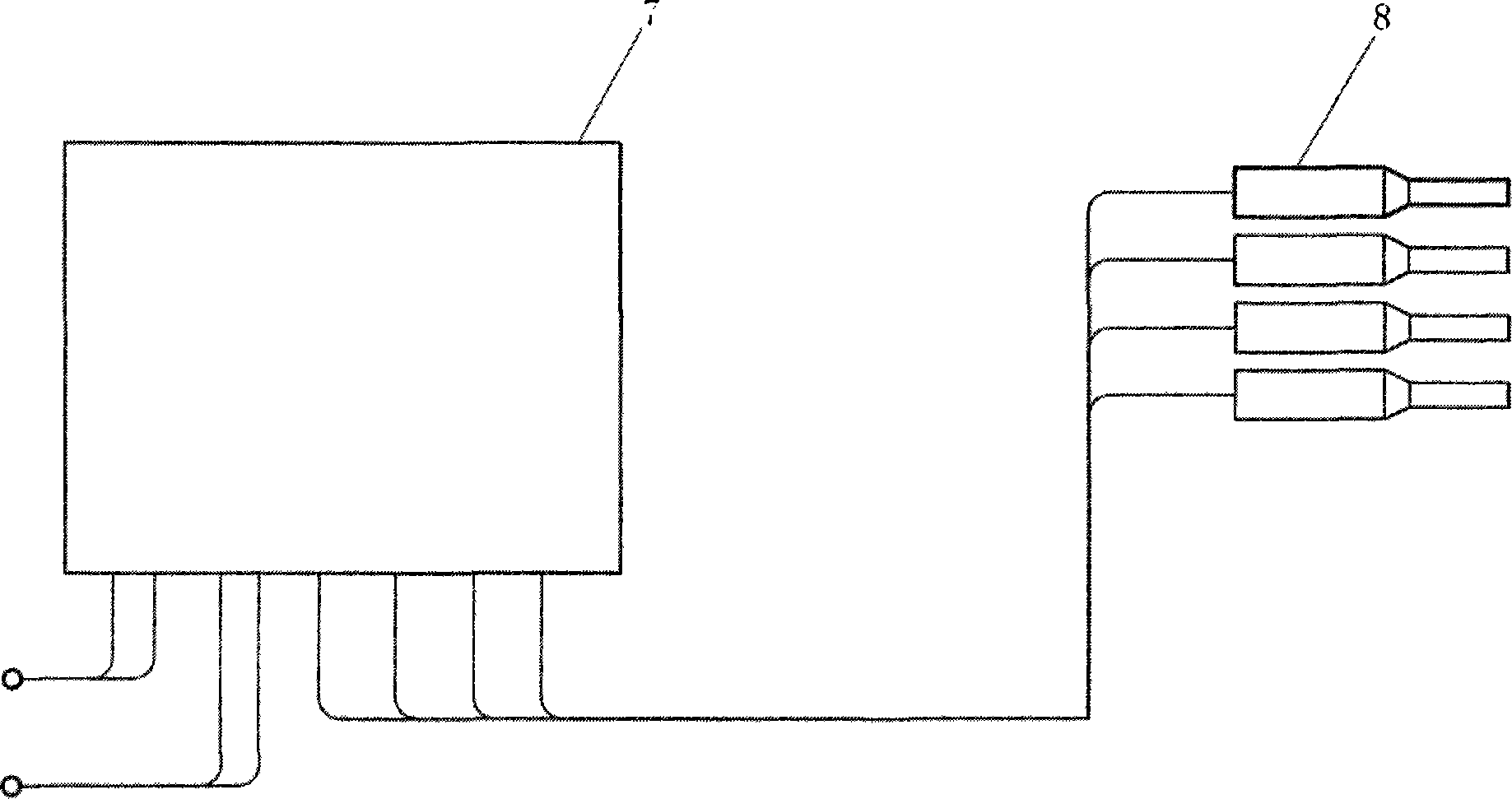

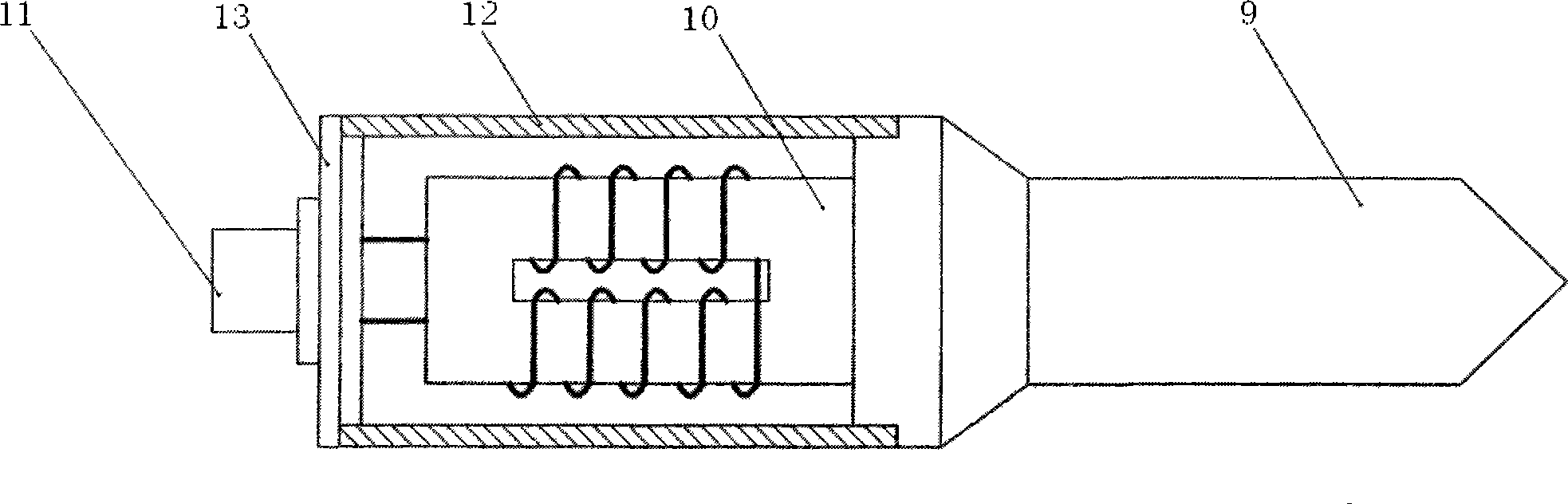

[0067] Such as figure 1 , figure 2As shown, the condenser online ultrasonic cyclone descaling device described in the embodiment of the present invention consists of an ultrasonic descaling device 4, a cyclone descaling device 6, a display operating system 1, a data acquisition and control device 2, and a power control device 5 components, the display operating system 1 and the data acquisition and control device 2 are connected through the RS485 bus, and the data acquisition and control device 2 is respectively connected to the ultrasonic descaling device 4, the cyclone descaling device 6, and the power control device 5. The transducer 8 of the ultrasonic descaling device 4 is fixed together with the condenser 3, and the cyclone descaling device 6 is fixed in the condenser 3 and connected to the power control device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com