Multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting carbon/carbon crucible and method using same

A deposition chamber and densification technology, applied in the field of carbon/carbon crucible material preparation for single crystal silicon furnace, can solve the problems of large vertical density difference, low production efficiency, low densification efficiency, etc. Simple structure and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

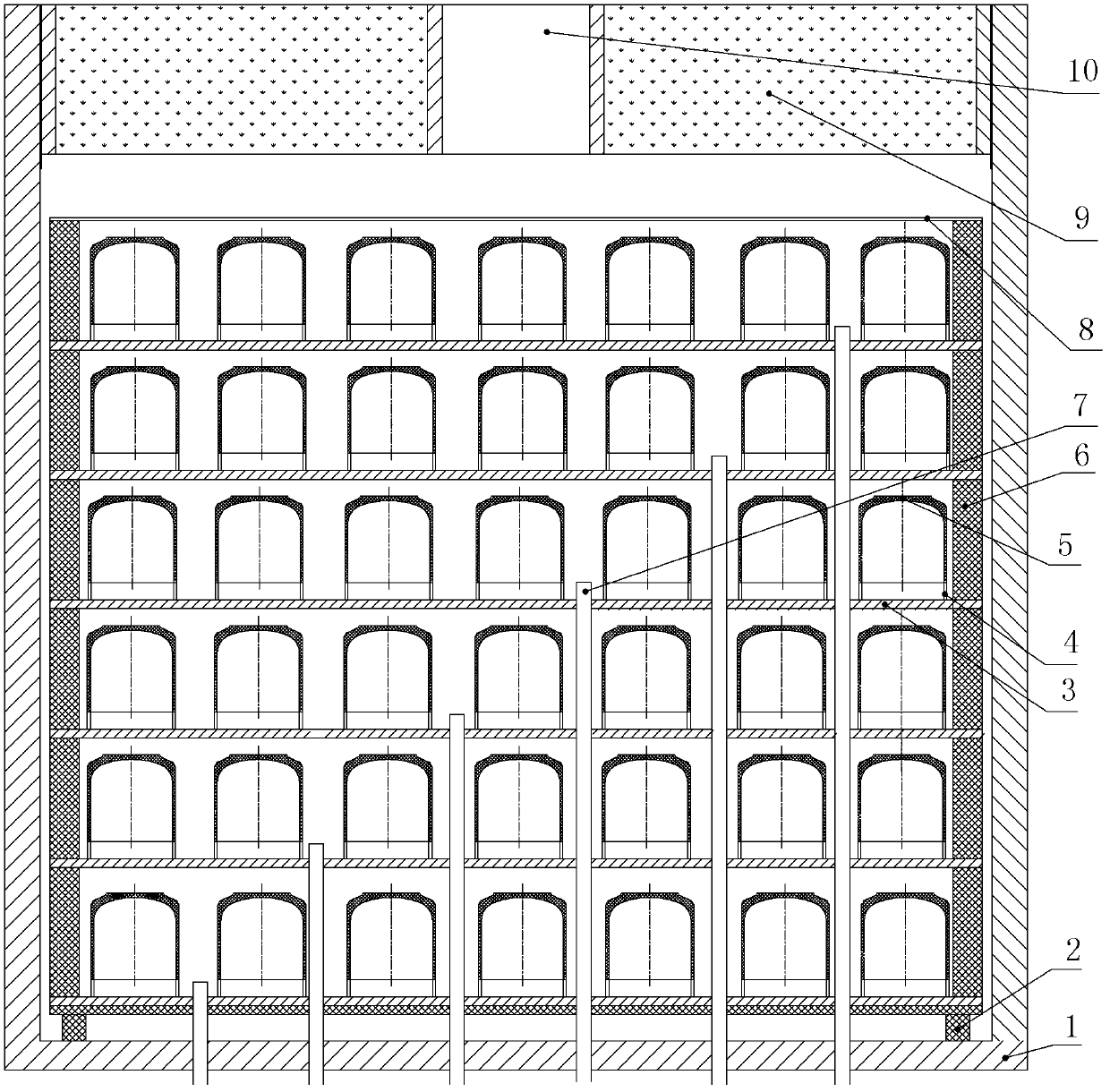

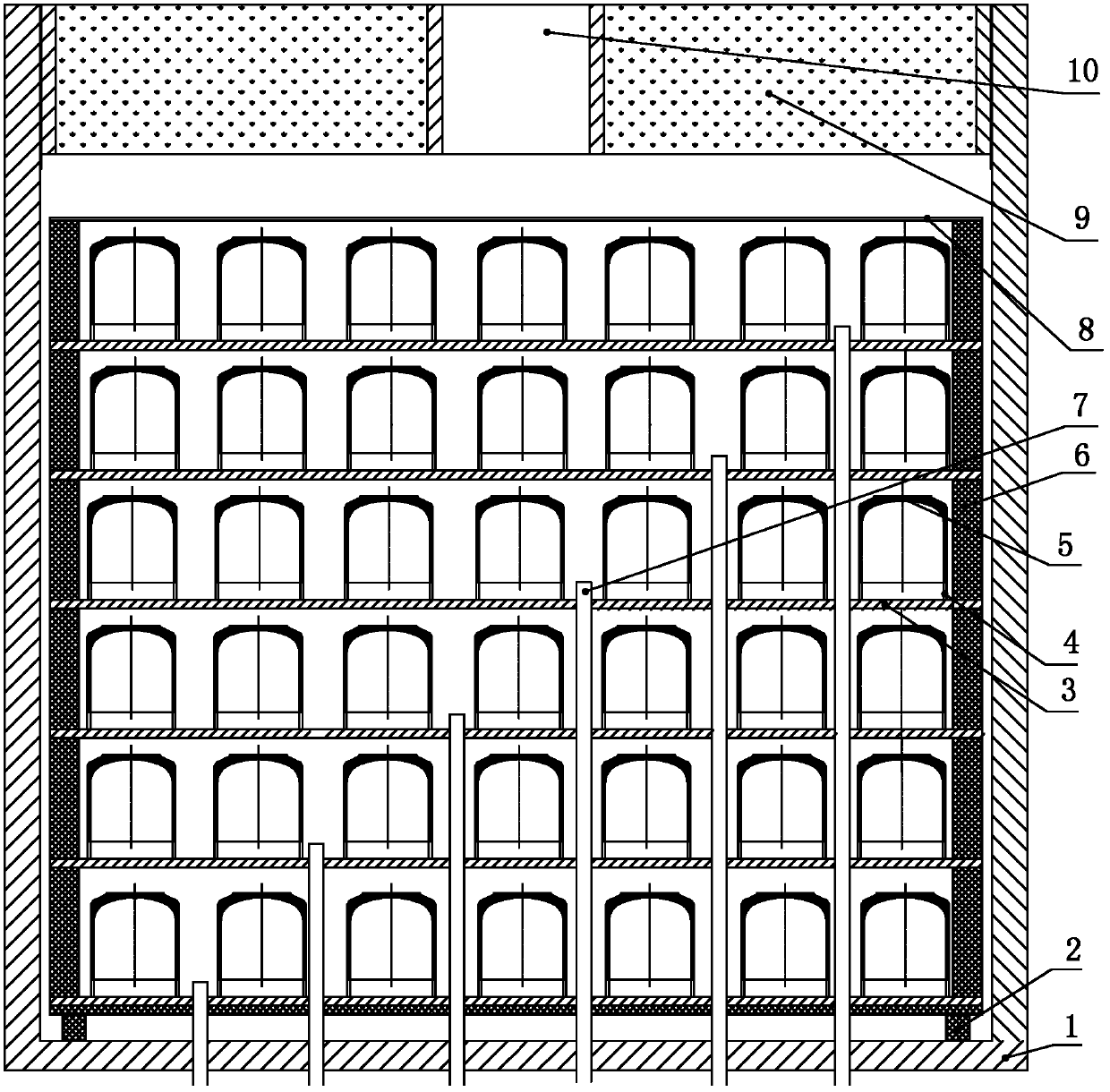

[0037] Such as figure 1 The shown multi-deposition chamber CVI dense carbon / carbon crucible device includes a chemical vapor deposition furnace composed of a furnace outer tank and a furnace inner tank 1, and also includes a bottom-to-top arrangement in the furnace inner tank 1 and is arranged horizontally The multi-layer graphite separator 3, a plurality of intake pipes 7 inserted into the furnace tank 1 from bottom to top and the furnace cover 9 sealed and installed on the furnace tank 1, between the graphite separators 3 of two adjacent layers They are all separated by a plurality of graphite support columns 6 arranged vertically, and the plurality of graphite support columns 6 are arranged along the outer edge line of the graphite separator 3 . The inner bottom of the furnace tank 1 is provided with a graphite support 2 for horizontal laying of the graphite separator 3 at the bottom, and the graphite support 2 is arranged horizontally. The multiple layers of graphite sepa...

Embodiment 2

[0061] In this embodiment, the device of the multi-deposition chamber CVI dense carbon / carbon crucible is different from Embodiment 1 in that: the number of the deposition chambers is 7, and 7 dense carbon / carbon crucibles are placed on each deposition chamber Prefabricated body 5, the number of the inlet pipe 7 is 7 and its diameter is Φ20mm, the height of the inlet pipe 7 inserted into the deposition chamber is 30mm, the inner diameter of the carbon / carbon composite ring plate is 1500mm, the outer Diameter is 2500mm and its thickness is 60mm, and the outer diameter of graphite inner plate is 1600mm and its thickness is 60mm, and the diameter of described graphite support column 6 is 150mm and its height is 550mm, and the thickness of described graphite spacer 4 is 50mm, The gas seal plate 8 has a diameter of 2500 mm and a thickness of 10 mm.

[0062] In this embodiment, the structure, connection relationship and working principle of the rest of the device of the multi-deposi...

Embodiment 3

[0066] In this embodiment, the difference between the device of the multi-deposition chamber CVI dense carbon / carbon crucible used in Example 1 is that the number of the deposition chambers is 8, and 8 compact carbon / carbon crucibles are placed on each deposition chamber Prefabricated body 5, the number of the inlet pipe 7 is 8 and its diameter is Φ30mm, the height of the inlet pipe 7 inserted into the deposition chamber is 40mm, the carbon / carbon composite material ring plate is 1700mm, the outer diameter is 3000mm and its thickness is 80mm, the outer diameter of graphite inner plate is 1800mm and its thickness is 80mm, the diameter of described graphite support column 6 is 200mm and its height is 600mm, the thickness of described graphite spacer 4 is 60mm, air-tight The diameter of the plate 8 is 3000 mm and its thickness is 20 mm.

[0067] In this embodiment, the structure, connection relationship and working principle of the rest of the device of the multi-deposition chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com