Modified ethylene propylene diene monomer

A modified technology of EPDM rubber, which is applied in the field of rubber material processing, can solve the problems of low oxygen index of EPDM rubber, limited promotion and application, etc., and achieve excellent elongation at break, good volume resistivity, The effect of hyperoxic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

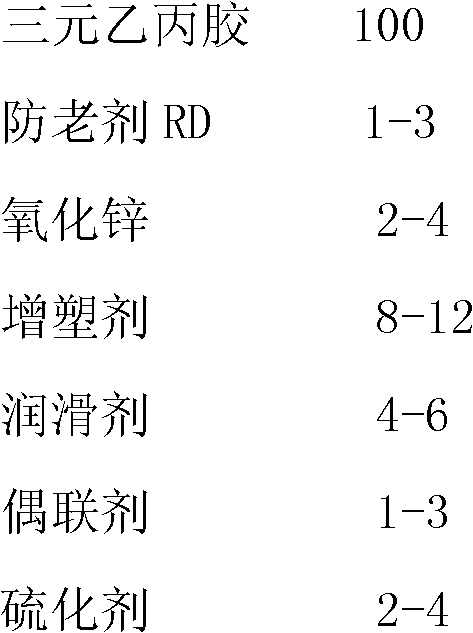

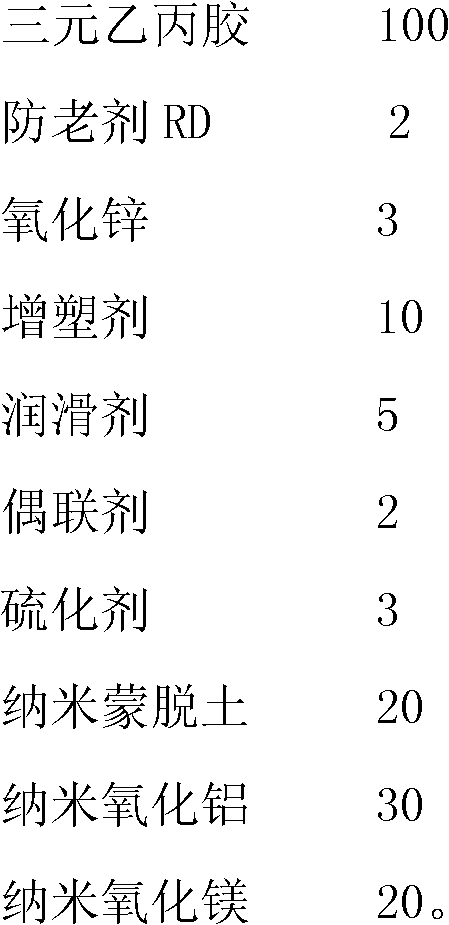

[0016] A modified EPDM rubber, which is made from the following raw materials in parts by weight:

[0017]

[0018] Plasticizer is No. 38 cylinder oil; Described lubricant is microcrystalline paraffin; Described coupling agent is silicon

[0019] Alkane coupling agent YGO-1204; the vulcanizing agent is sulfur.

[0020] The preparation method is as follows:

[0021] Add EPDM rubber, nano-montmorillonite, nano-alumina, nano-magnesia, anti-aging agent, and plasticizer into the internal mixer according to the formula ratio, start the internal mixer, fully mix several raw materials, and wait for the compaction When the temperature of the mixing room reaches 120°C, the mixed rubber material is released from the internal mixing room, put into the open mill for masticating, filtered through the rubber filter, and then rolled, and then added with a vulcanizing agent for secondary mixing, and the production The modified EPDM rubber was obtained.

[0022] Experimental data

[0023...

example 2

[0027] A modified EPDM rubber, which is made by mixing two parts A and B.

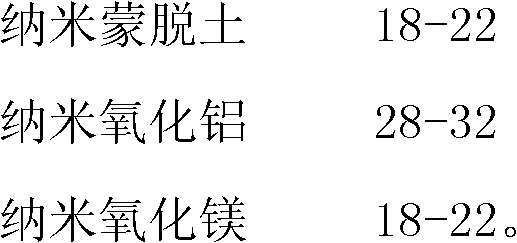

[0028] Component A is made from the following raw materials in parts by weight:

[0029]

[0030] Plasticizer is No. 38 cylinder oil; Described lubricant is microcrystalline paraffin; Described coupling agent is silicon

[0031] Alkane coupling agent YGO-1204; the vulcanizing agent is sulfur.

[0032] Add EPDM rubber, nano-montmorillonite, nano-alumina, nano-magnesia, anti-aging agent, and plasticizer into the internal mixer according to the formula ratio, start the internal mixer, fully mix several raw materials, and wait for the compaction When the temperature of the mixing room reaches 120°C, the mixed rubber material is released from the internal mixing room, put into the open mill for masticating, filtered through the rubber filter, and then rolled, and then added with a vulcanizing agent for secondary mixing, and the production Get A component.

[0033] Component B is made from the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com