Method for preparing amino-terminated polyurethane

A technology of amino-terminated polyurethane and hydroxyl-terminated polyurethane, which is applied in the field of preparation of active amino-terminated functional compounds, and can solve problems such as poor fatigue resistance, heat resistance and impact resistance, affecting the performance of amino-terminated polyurethane, and difficulty in guaranteeing the performance of sprayed products, etc. , to achieve low cost, reduce production risk, and inhibit the generation of cross-linked structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

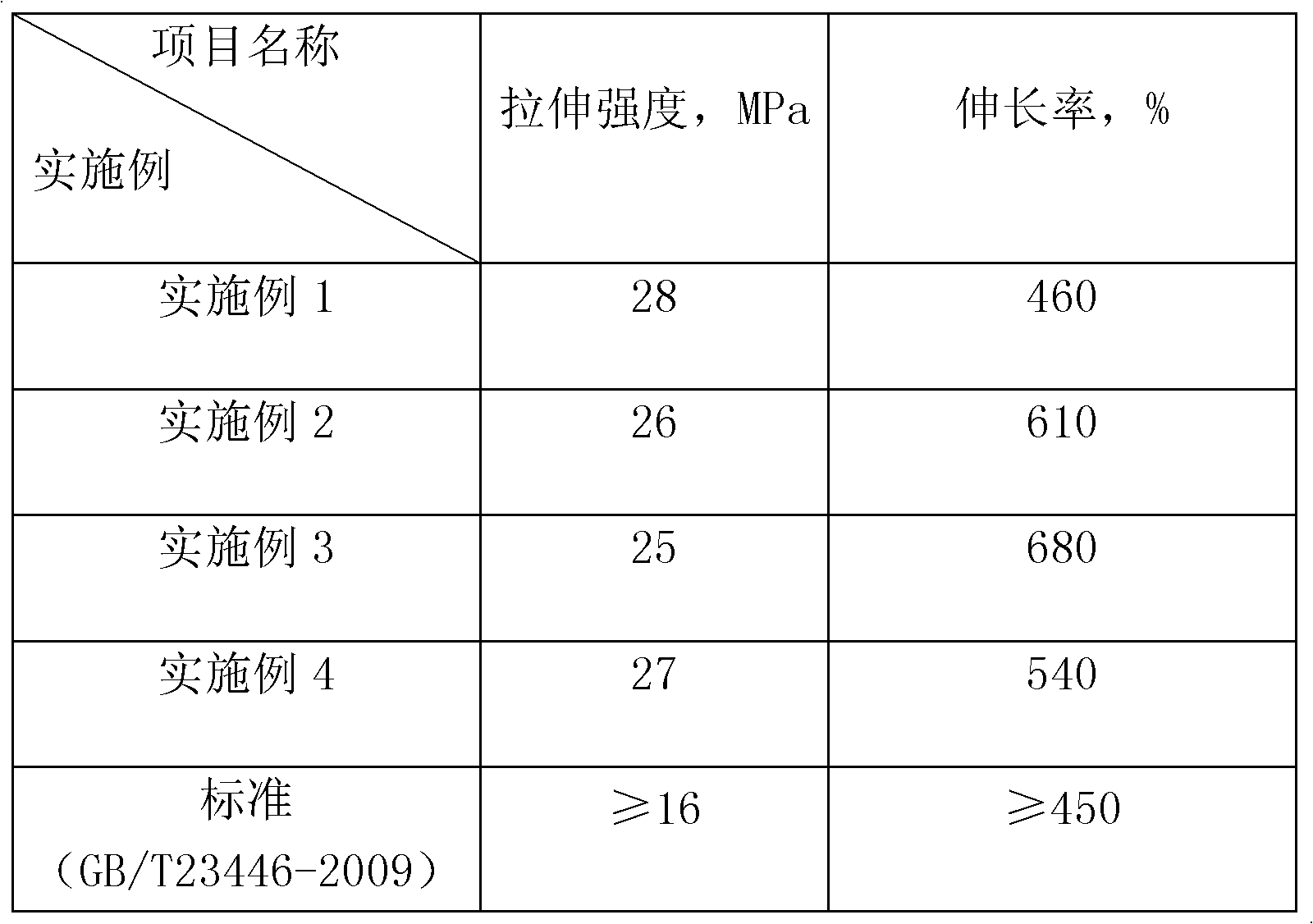

Examples

Embodiment 1

[0017] Step 1: Add 10 mol of propylene oxide homopolyether diol with a molecular weight of 400 into the reactor, vacuum dehydrate at 90-100°C for 1-2 hours, take samples to measure the moisture content, when the moisture content is less than 0.08%, Stop dehydration, cool to 70-75°C and maintain at this temperature range, add organic bismuth BiCAT catalyst, add 10mol MDI dropwise while stirring, continue to keep warm for 3 hours after the dropwise addition, and obtain hydroxyl-terminated polyurethane with an average molecular weight of 1050.

[0018] The second step: Slowly add the hydroxyl-terminated polyurethane obtained in the first step into another kettle equipped with 20mol IPDI and organic bismuth BiCAT catalyst under rapid stirring, and react for 3 hours to obtain an isocyanate-terminated polyurethane with an average molecular weight of 1495.

[0019] The third step: lower the temperature to below 30°C, under the condition of rapid stirring, slowly add the product obtain...

Embodiment 2

[0021] Step 1: Add 10 mol of ethylene oxide homopolyether diol with a molecular weight of 1000 into the reaction kettle, vacuum dehydrate at 90-100°C for 1-2 hours, take samples to measure the moisture content, when the moisture content is less than 0.08% , stop dehydration, cool to 70-75°C and maintain at this temperature range, add an organotin catalyst, add 10mol MDI dropwise while stirring, continue to keep warm for 3 hours after the dropwise addition, and obtain a hydroxyl-terminated polyurethane with an average molecular weight of 2250.

[0022] The second step: Slowly add the hydroxyl-terminated polyurethane obtained in the first step into another kettle equipped with 20 mol of IPDI and organic bismuth BiCAT catalyst under rapid stirring, and react for 3 hours to obtain an isocyanate-terminated polyurethane with an average molecular weight of 2695.

[0023] The third step: lower the temperature to below 30°C, under the condition of rapid stirring, slowly add the product ...

Embodiment 3

[0025] Step 1: Add 10 mol of ethylene oxide / propylene oxide copolyether diol with a molecular weight of 2000 into the reaction kettle, vacuum dehydrate at 90-100°C for 1-2 hours, take samples to measure the moisture content, when the moisture content is less than 0.08%, stop dehydration, cool to 70-75°C and maintain at this temperature range, add organotin and organobismuth BiCAT in a mass ratio of 1:1 composition, add 10mol HDI dropwise while stirring, continue to Insulated for 3 hours to obtain a hydroxyl-terminated polyurethane with an average molecular weight of 4250.

[0026] The second step: Slowly add the hydroxyl-terminated polyurethane obtained in the first step into another kettle equipped with 20 mol of IPDI and organic bismuth BiCAT catalyst under rapid stirring, and react for 3 hours to obtain an isocyanate-terminated polyurethane with an average molecular weight of 4695.

[0027] The third step: lower the temperature to below 30°C, under the condition of rapid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com