Micro-nano cellulose and preparation method thereof

A technology of micro-nano cellulose and cellulose, which is applied in the field of materials, can solve the problems of complex operation, large equipment corrosion, and a large amount of acid waste liquid, and achieve the effects of mild reaction conditions, low equipment corrosion, and small degradation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

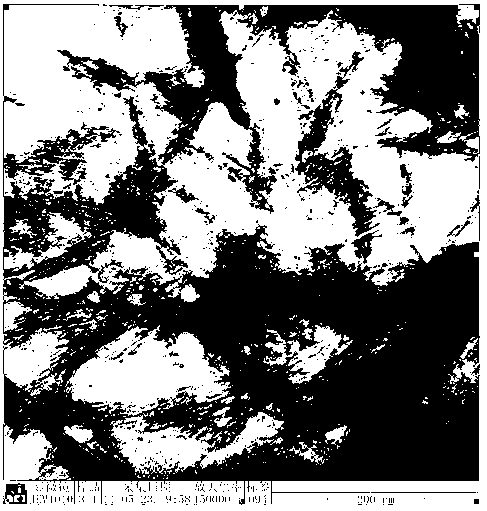

[0024] Take by weighing 2g microcrystalline cellulose, join the ZnCl of 30g mass fraction 60% 2 —In glycerin solution, 175°C oil bath for 4h to obtain cellulose / ZnCl 2 / glycerin mixture. Add 700 mL of distilled water to the cellulose / ZnCl 2 Glycerin / glycerin mixture, centrifuge and layer (centrifuge at 10,000 rpm, 15 min each time), remove the upper layer solution, and remove the lower layer of cellulose jelly to obtain micro-nano cellulose. It can be seen from the observation of the transmission electron microscope that the micro-nanocellulose prepared by this method has a diameter of about 10-20nm and a length of about 200nm, and has a rod-like and network-like structure, such as figure 1 shown.

Embodiment 2

[0026] Weigh 2g of chemical pulp, add to 30g of ZnCl with a mass fraction of 0.1% 2 —In glycerin solution, 240°C oil bath for 8h to obtain cellulose / ZnCl 2 / glycerin mixture. Add 700 mL of distilled water to the cellulose / ZnCl 2 Glycerin / glycerol mixture, centrifuge and layer (centrifuge at 5000 rpm, 10 min each time), remove the upper layer solution, and obtain micro-nano cellulose from the lower layer of cellulose jelly.

Embodiment 3

[0028] Weigh 0.5g absorbent cotton and add to 10g FeCl with a mass fraction of 60%. 3 —Glycerol-ethylene glycol solution (the mass ratio of glycerol and ethylene glycol is 1:1), oil bath at 100°C for 1h, to obtain cellulose / FeCl 3 / glycerin / glycol mixture. Add 700 mL of distilled water to the cellulose / FeCl 3 / glycerol / ethylene glycol mixture, centrifuge and layer (centrifuge at 5,000 rpm, 10 min each time), remove the upper layer solution, and remove the lower layer of cellulose jelly to obtain micro-nano cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com