Lower cover structure of frameless sterilizing tank

A technology of cover structure and sterilization tank, which is applied in the field of sterilization treatment equipment, can solve the problems of low operation efficiency and a large number of manual operations, and achieve the effect of improving operation efficiency, reducing costs and avoiding a large number of participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

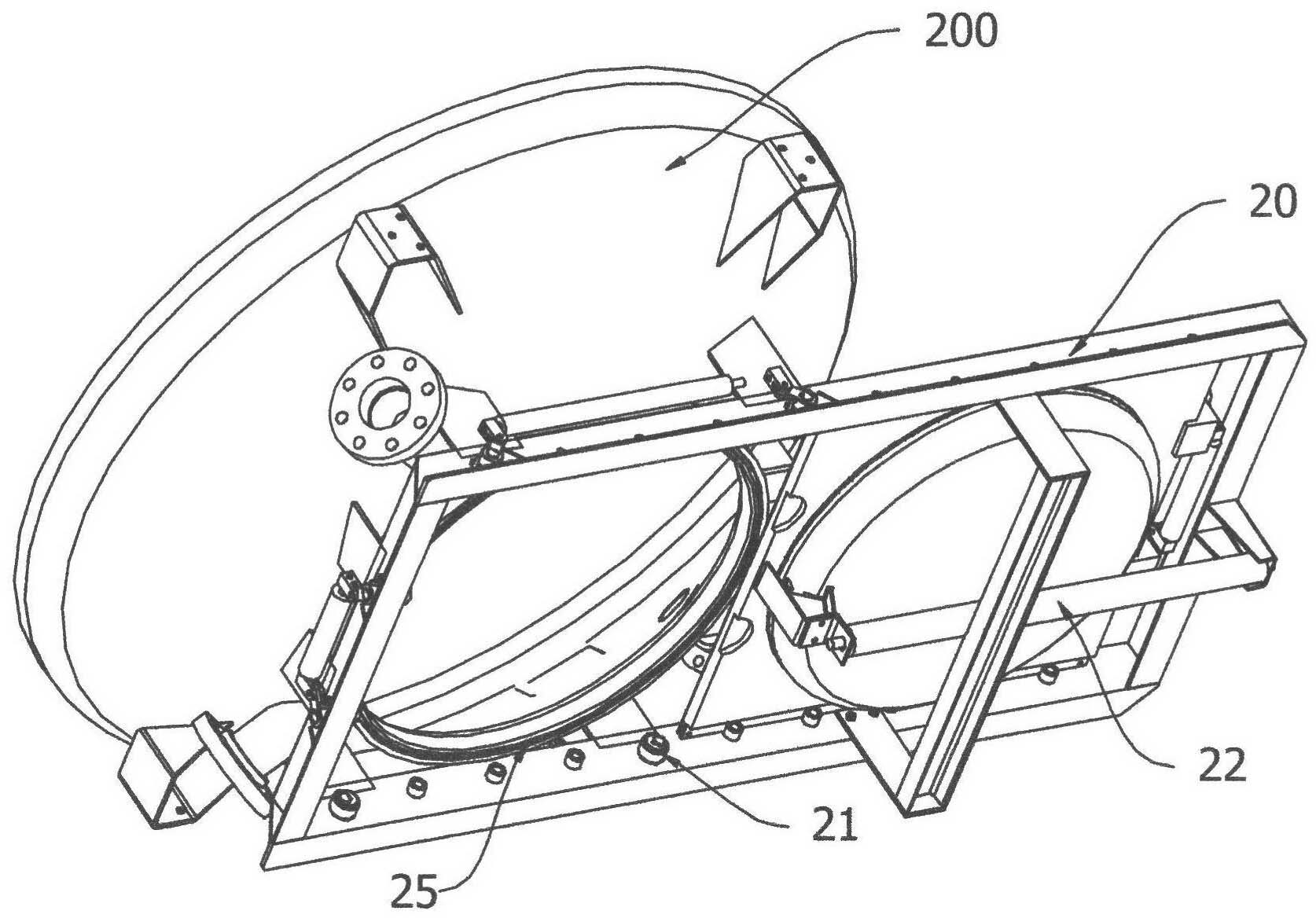

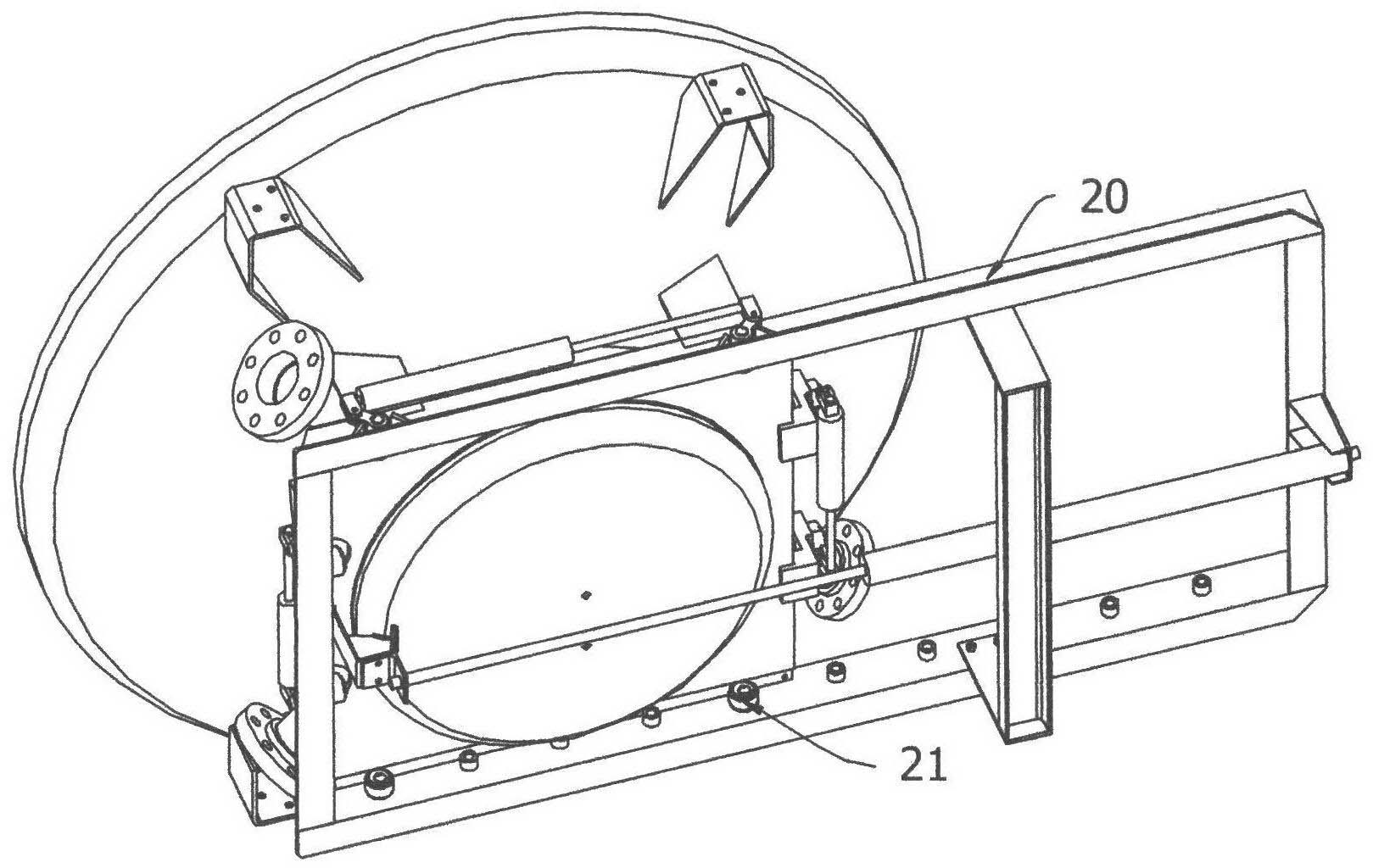

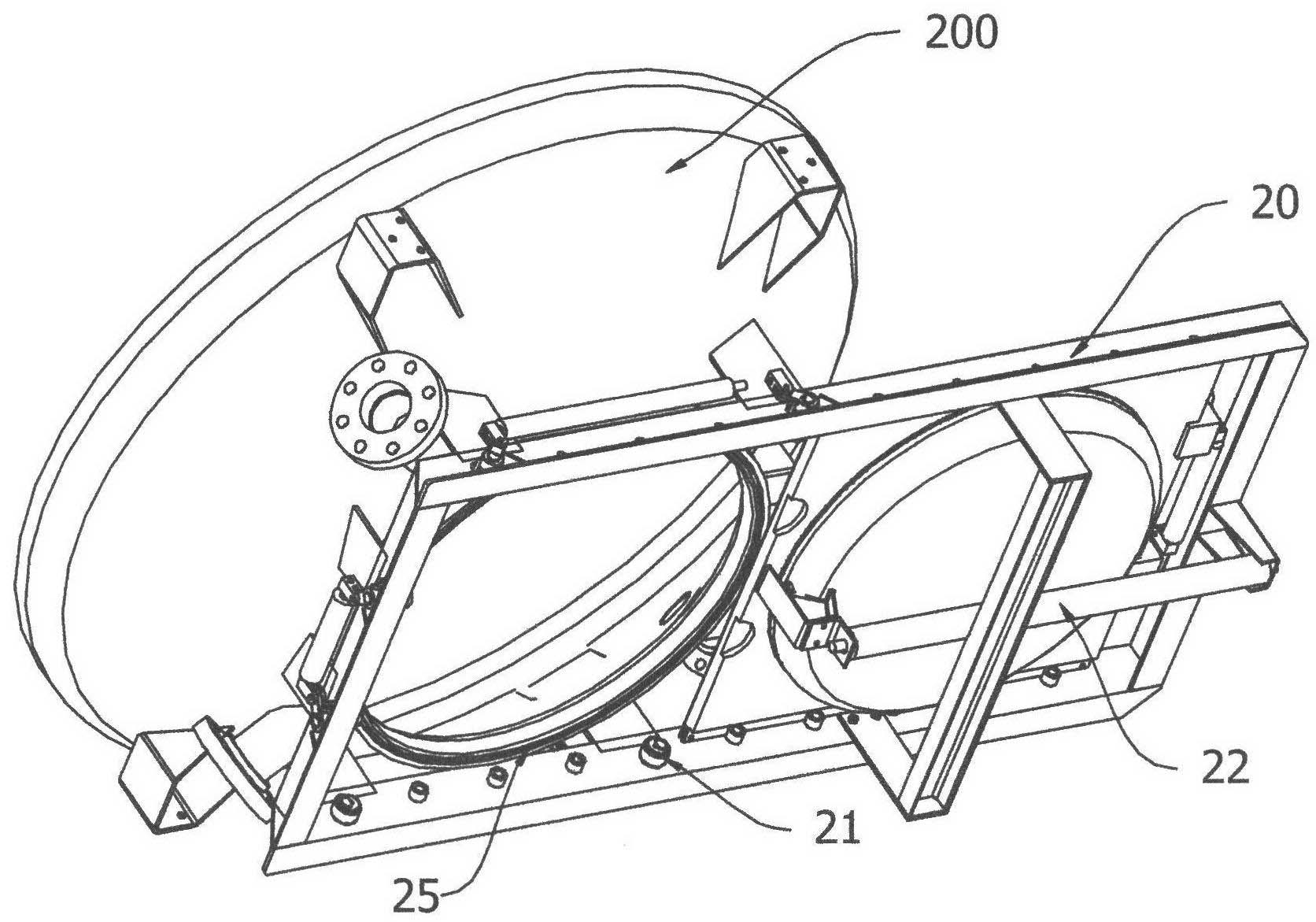

[0017] like figure 1 , figure 2 As shown, the lower cover structure 200 of the frameless sterilization tank of the present invention is a specific embodiment, a lower cover structure 200 of the frameless sterilization tank, and the lower cover structure 200 is a drawer-type quick-opening door structure.

[0018] The lower cover structure 200 includes a lower cover pressing device 20 . The lower cover pressing device 20 is a square structure. The lower cover pressing device 20 includes a lower cover body, a displacement cylinder 22 linked with the lower cover body, an eccentric cam 21 arranged inside the lower cover pressing device 20 , and a sealing ring arranged at the bottom of the lower cover structure 200 . Due to the use of the sealing ring at the lower part of the lower cover structure 200, the reduction of the sterilization effect caused by the poor sealing of the lower cover structure 200 is avoided.

[0019] The lower cover structure 200 also includes a water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com