Multi-crystallizer horizontal continuous casting pouring box and continuous casting process implemented by using same

A technology of horizontal continuous casting and continuous casting process, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of low production efficiency, poor use effect, large safety hazards, etc., to improve production efficiency and casting success rate , The effect of improving work efficiency and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

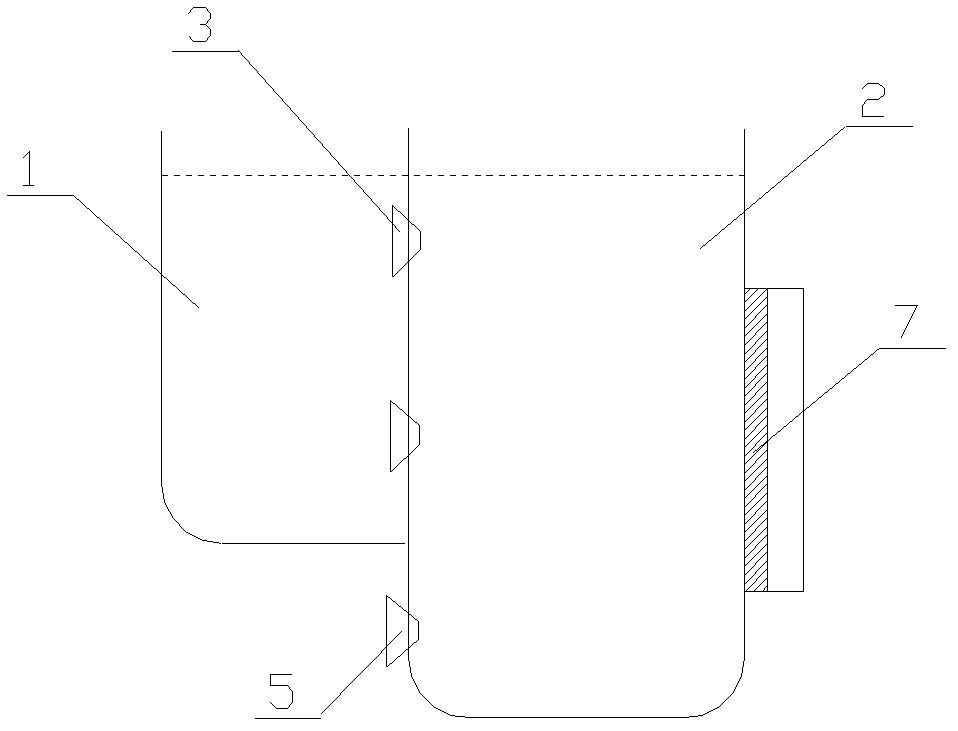

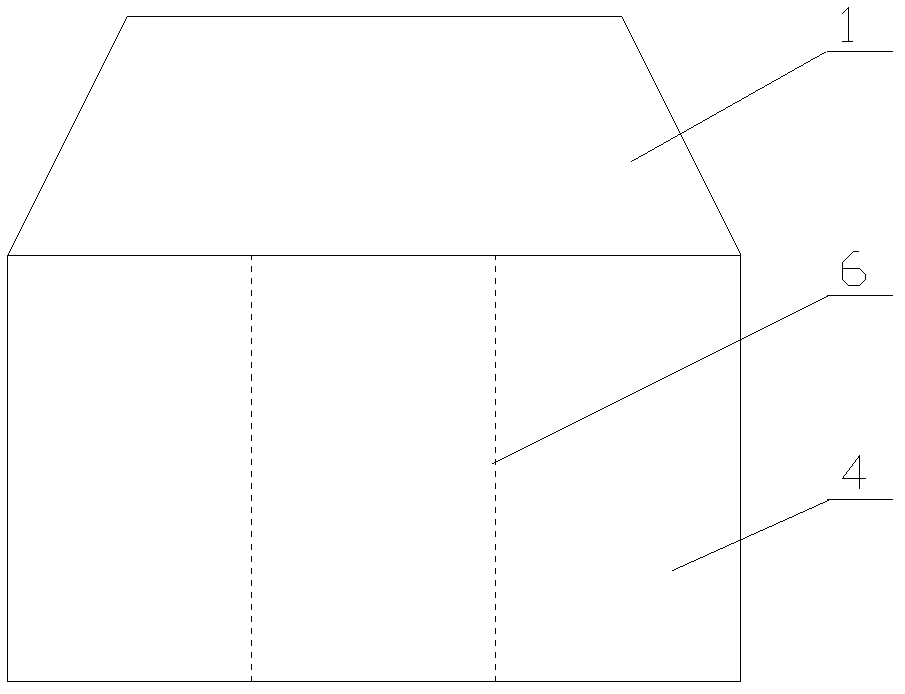

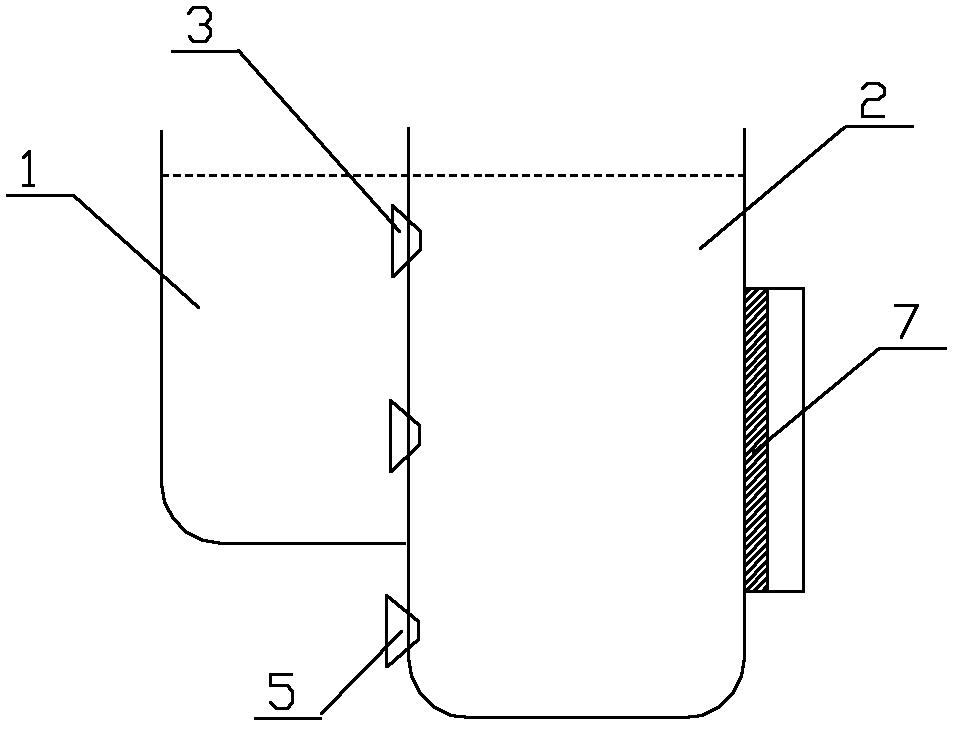

[0018] A multi-crystallizer horizontal continuous casting tundish is a double tundish composed of a diversion ladle 1 and a pouring ladle 2, which can be directly divided by a partition wall. The diversion bag 1 and the pouring bag 2 are connected through several diversion tubes 3, and the apertures of the diversion tubes 3 are set according to the different heights, among which the aperture at the bottom is the largest, the aperture at the upper part is the smallest, and the aperture at the side is the largest. The aperture of the side is larger than that in the middle, and the diversion pipe 3 is trumpet-shaped, and the diversion bag 1 is flushed with a large mouth. The pouring ladle 2 is provided with partitions 4 that can be divided into several pouring chambers 6, and the side walls of each pouring chamber 6 are provided with holes for installing crystallizers 7, and at the bottom of each pouring chamber 6 At least one emergency discharge port 5 is provided, and a dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com