Energy-saving type three-temperature-output water boiler

An energy-saving, water boiling technology, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problem of not being able to output drinking water, and achieve the effect of shortening the power of the heater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

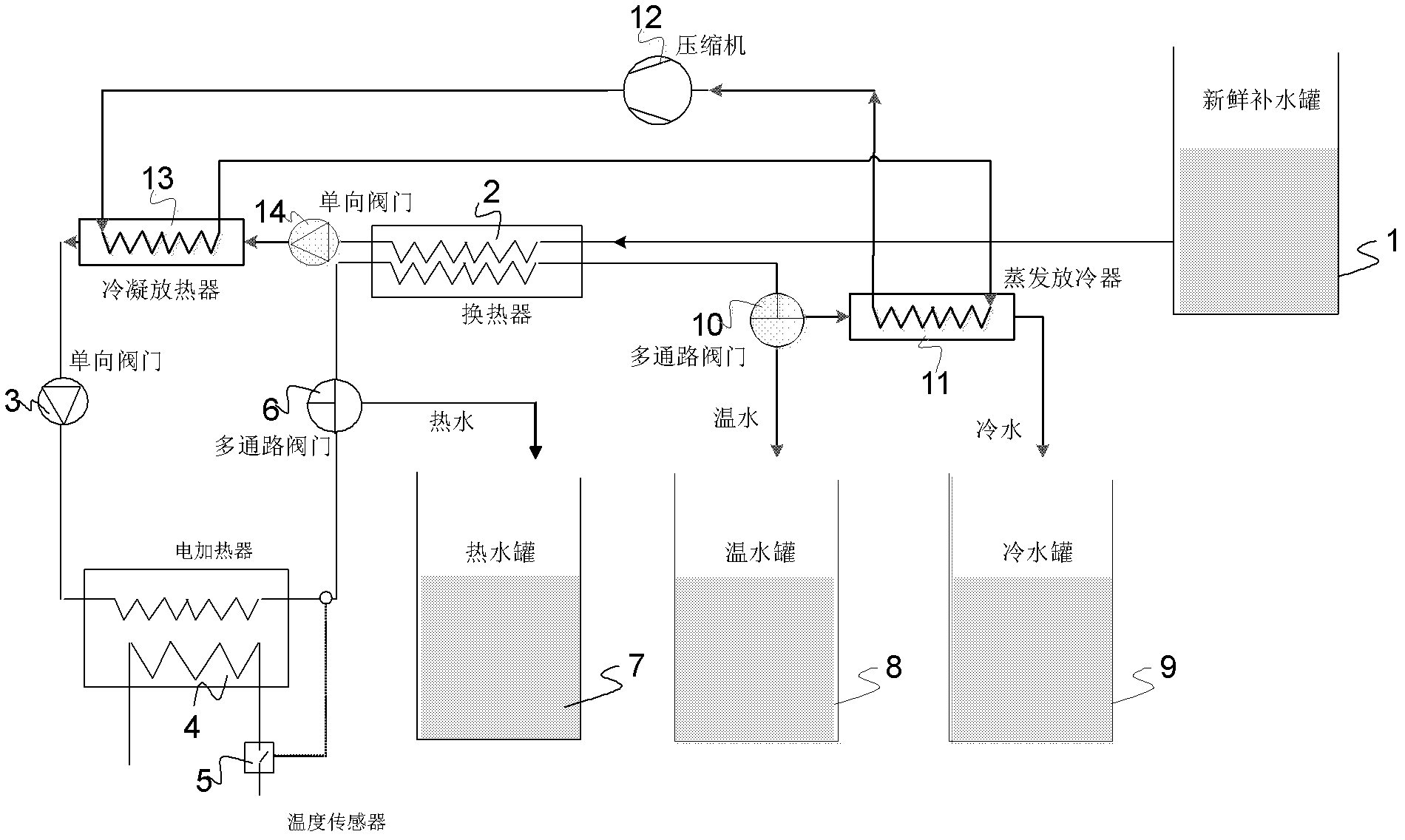

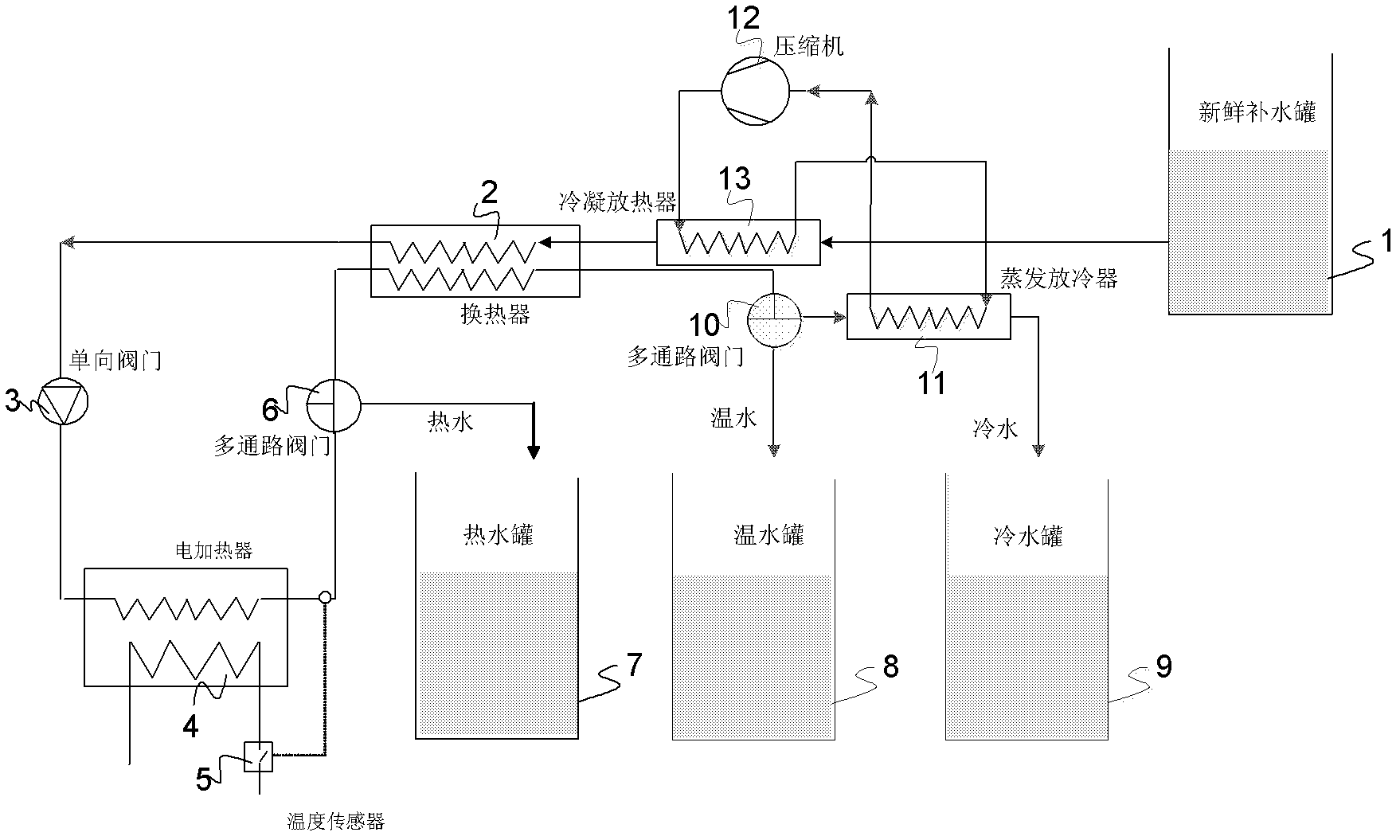

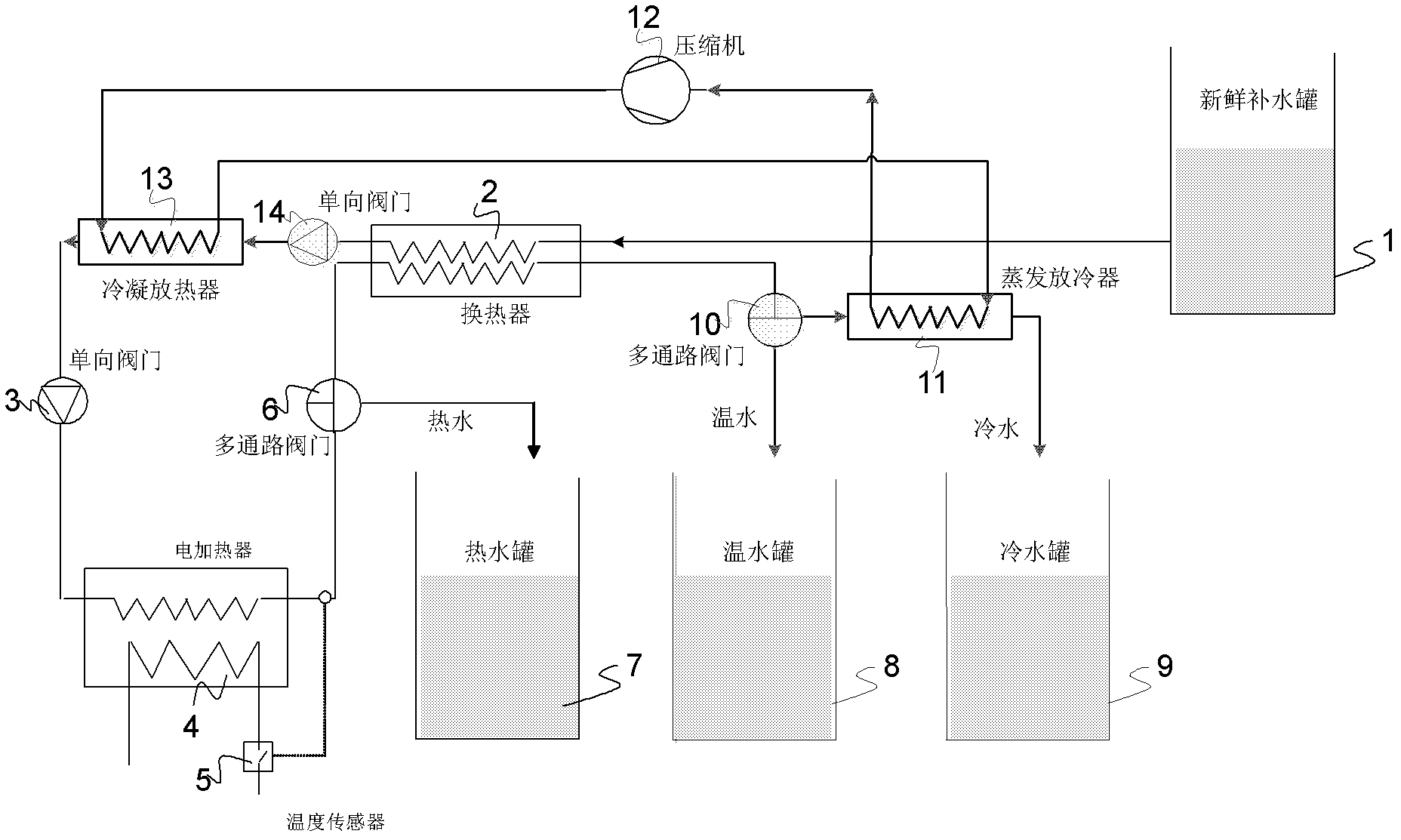

[0027] Example: using figure 1The process flow shown is calculated by heating 10 liters of boiling water per hour as an example. The water supply temperature used is 25°C, the water supply preheating temperature is 80°C, the boiling water temperature is 100°C, the boiling water vaporization rate is 1%, the electric heater input power is 0.288kw, the warm water output temperature is 50°C, and the cold water output temperature is 20 °C. Heat exchanger surface area 0.0342m 2 . The surface area of the heat exchanger is taken as the total heat transfer coefficient of 0.02 cal s -1 m -2 ·K -1 calculate. If the heat pump efficiency COP is calculated as 1, compared with the water boiler without heat exchanger and heat pump, the energy saving rate is about 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com