Layered composite tissue shaft parts material and its preparation method

A technology of composite structure and shaft parts, applied in the direction of shaft, temperature control, shaft and bearing, etc., can solve the problems of rolling holes and porosity, and achieve the effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

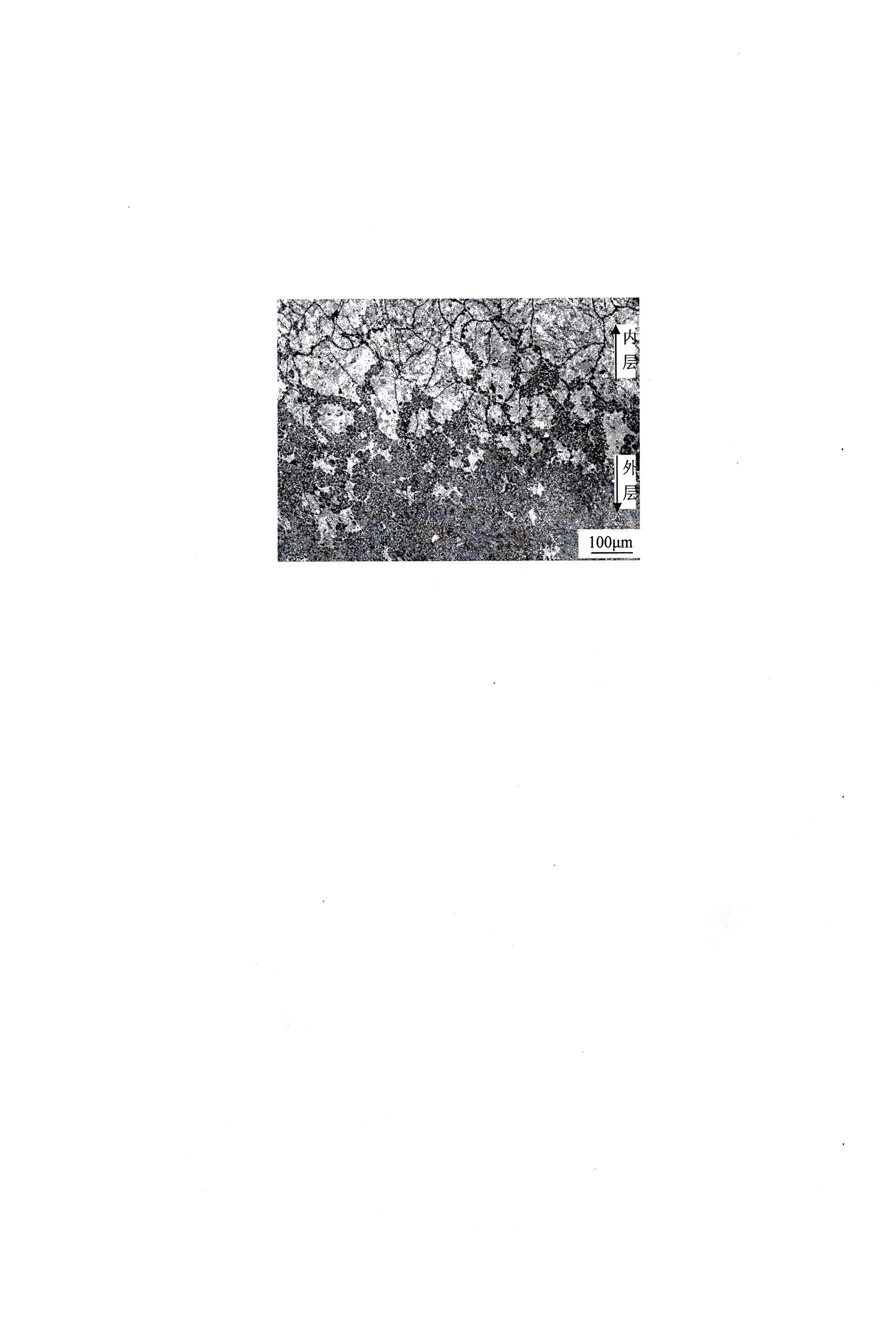

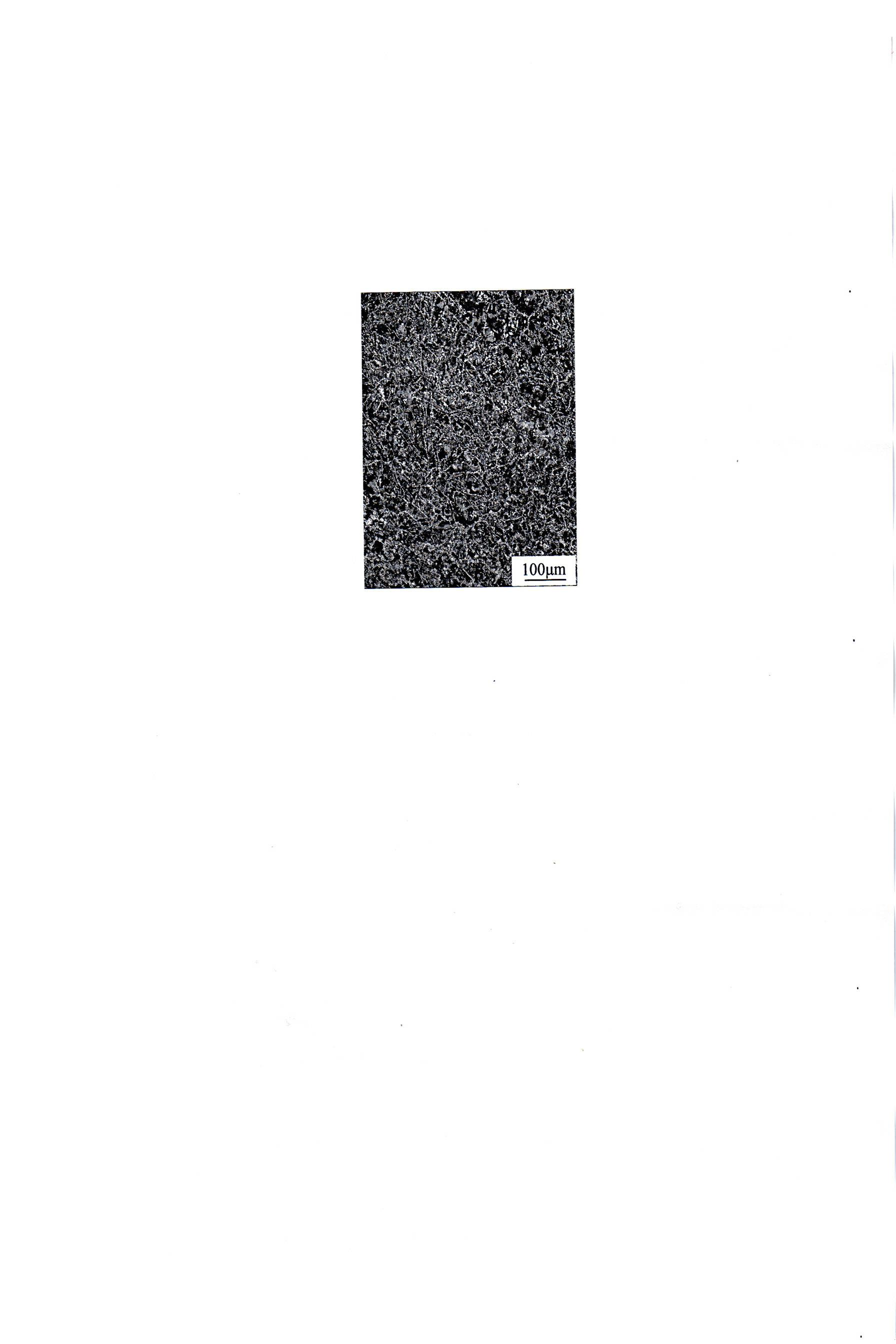

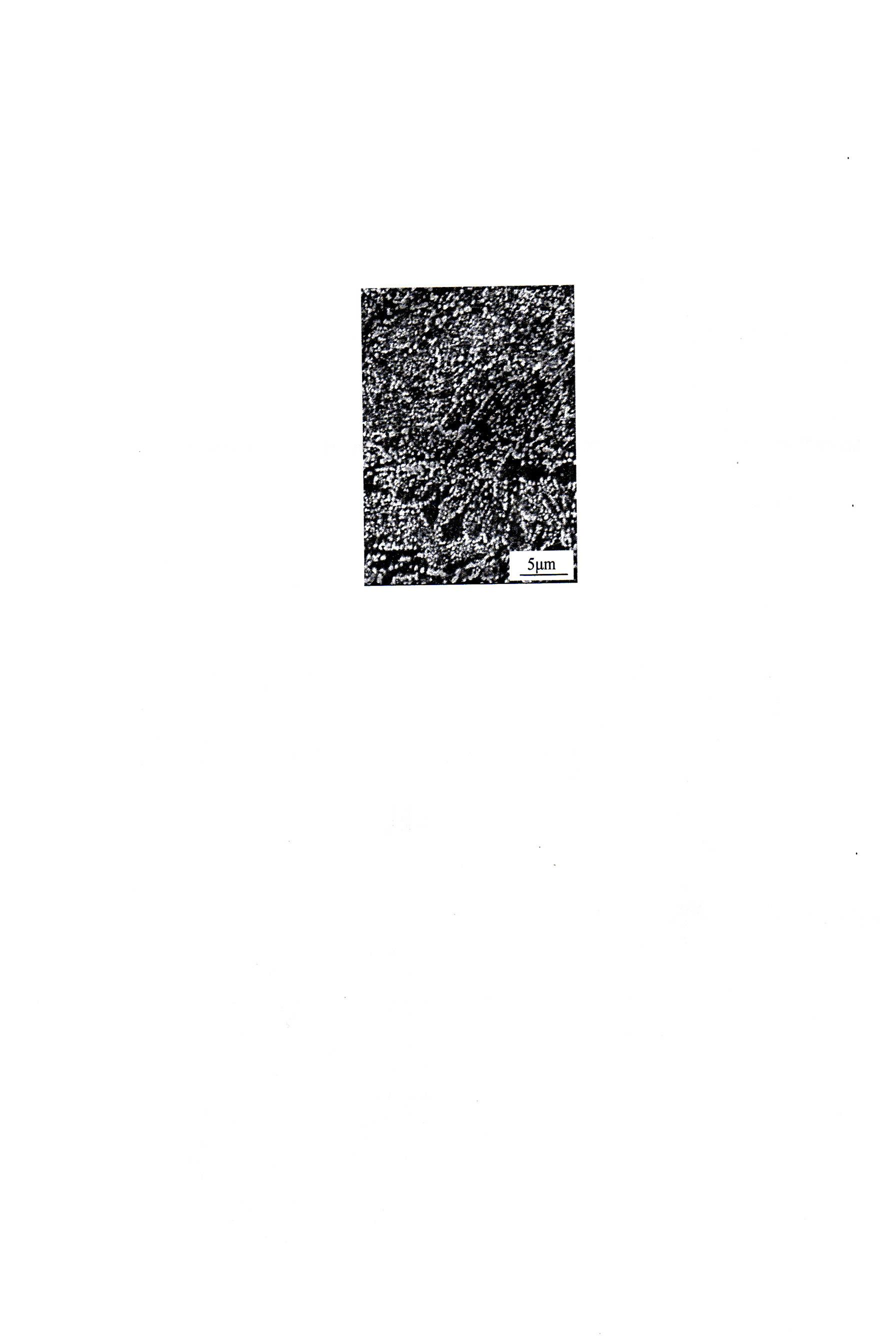

[0011] Example 1: The chemical composition is C 0.50 wt%, Si 0.37 wt%, Mn 0.80 wt%, Cr 0.4 wt%, Ni 0.30 wt%, Pfigure 1 ; figure 2 Metallographic photograph of flaky pearlite and proeutectoid ferrite in the center; image 3 It is a composite structure of micron-sized ferrite and fine cementite particles in the outer layer.

Embodiment 2

[0012] Example 2: The chemical composition is C 0.40 wt %, Si 0.25 wt %, Mn 0.75 wt %, Cr 1.05 wt %, Mo 0.20 wt %, P2 ) greater than 45.

Embodiment 3

[0013] Example 3: A medium-carbon low-alloy steel whose chemical composition is C 0.95 wt %, Si 0.21 wt %, Mn 0.30 wt %, Cr 1.2 wt %, P<0.03 wt %, S<0.02 wt %, and the balance is Fe φ60 bar, heated to the rolling temperature of 1050 °C, took out the bar, put it into 20 °C water for 5 s and quickly took it out, at this time the surface temperature of the rolled billet bar was about 600 °C, and the core was still 1050 °C ℃, carry out cross rolling forming, the average reduction is about 20%, after forming, air cool for 15s and then oil cool to room temperature. During the forming process, due to the presence of a low-temperature hard shell on the surface of the bar, the stress conditions during the rolling process of the rolled piece are changed, and there are no defects such as rolling looseness in the center of the rolled piece. It is thin, and obviously different from the core structure, with obvious structure layering characteristics. The core is pearlite and bainite structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com