Preparation method for ordered mesoporous gamma-Al2O3

A technology of ordered mesoporous and mesoporous, which is applied in the field of preparation of ordered mesoporous γ-Al2O3, can solve the problems of complex process, low thermal stability, and small specific surface of mesoporous alumina, and achieve large specific surface area and pore diameter Narrow distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Synthesis reaction: Dissolve 1.0 g of P123 in 20 mL of absolute ethanol, add mixed acid (concentrated hydrochloric acid: citric acid: glacial acetic acid = 2:1:2) while stirring, and adjust the pH to 3~4. After clarification, add 10 mmol aluminum isopropoxide, seal with PE film, and continue to stir for 5 h.

[0027] B. Aging: Put the solution in step A into aging for 10 h to obtain a transparent gel.

[0028] C. Drying: transfer the gel in step B to a 60 °C oven for 48 h to obtain a white powder.

[0029] D. Calcination: heat the white powder in step C to 550°C at a rate of 1°C / min in an oxygen atmosphere for 6 hours, then raise the temperature to 700°C at a rate of 10°C / min and hold for 1 hour.

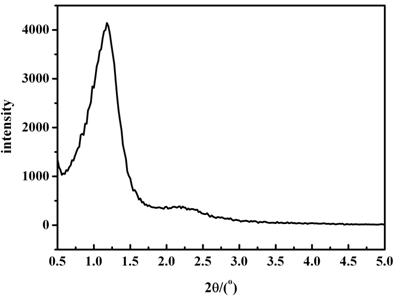

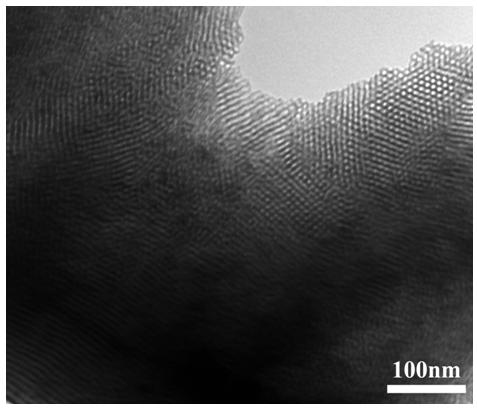

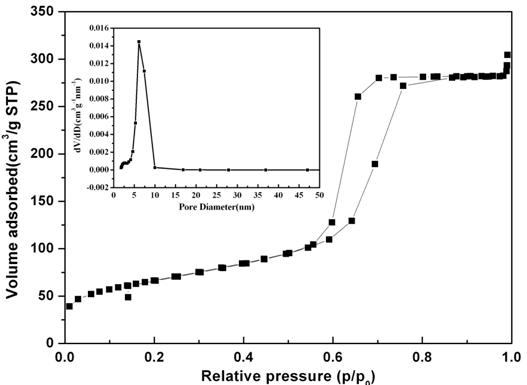

[0030] The product obtained by this method is ordered mesoporous γ-Al 2 o 3 , the small angle XRD pattern of this product ( figure 1 ) and TEM ( figure 2 ) It can be seen that the product channels are arranged in a two-dimensional regular hexagon, and the order i...

Embodiment 2

[0032] A. Synthesis reaction: Dissolve 1.0 g P123 in 20 mL of absolute ethanol, add mixed acid (concentrated nitric acid: citric acid: glacial acetic acid = 2.5:1:1) while stirring, and adjust the pH to 3~4. After clarification, add 10 mmol aluminum isopropoxide, seal with PE film, and continue to stir for 5 h.

[0033] B. Aging: Put the solution in step A into aging for 10 h to obtain a transparent gel.

[0034] C. Drying: transfer the gel in step B to a 60 °C oven for 48 h to obtain a white powder.

[0035] D. Calcination: heat the white powder in step C to 550°C at a rate of 1°C / min in an oxygen atmosphere for 6 hours, then raise the temperature to 700°C at a rate of 10°C / min and hold for 1 hour.

[0036] Mesoporous γ-Al 2 o 3 The specific surface area is 293.7 m 2 / g, pore volume 0.49 m 3 / g, and the average pore diameter is 9.9 nm. The product has better orderliness than the product of Embodiment 1, as shown by the XRD figure ( figure 2 )As can be seen.

Embodiment 3

[0038] A. Synthesis reaction: Dissolve 1.0 g P123 in 20 mL absolute ethanol, add mixed acid (concentrated hydrochloric acid: citric acid: glacial acetic acid = 2:1:2) while stirring, and adjust the pH to 3~4. After clarification, add 10 mmol aluminum isopropoxide, seal with PE film, and continue to stir for 5 h.

[0039] B. Aging: Put the solution in step A into aging for 10 h to obtain a transparent gel.

[0040] C. Drying: transfer the gel in step B to a 60 °C oven for 48 h to obtain a white powder.

[0041] D. Calcination: heat the white powder in step C to 550°C at a rate of 1°C / min in an oxygen atmosphere and keep it for 6 hours, then raise the temperature to 1000°C at a rate of 10°C / min and hold it for 1 hour.

[0042] Mesoporous γ-Al 2 o 3 The specific surface area is 181.23 m 2 / g, pore volume 0.23 m 3 / g, and the average pore diameter is 7.3 nm. The ordered mesoporous structure is still maintained, and the order is lower than that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com