Hydrogen sulfide leakage arresting agent

A technology of trapping agent and hydrogen sulfide, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of polluting the air, destroying the ecological environment, and many preparation steps, which is beneficial to production costs and reduces promotion. The effect of simplified application and preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

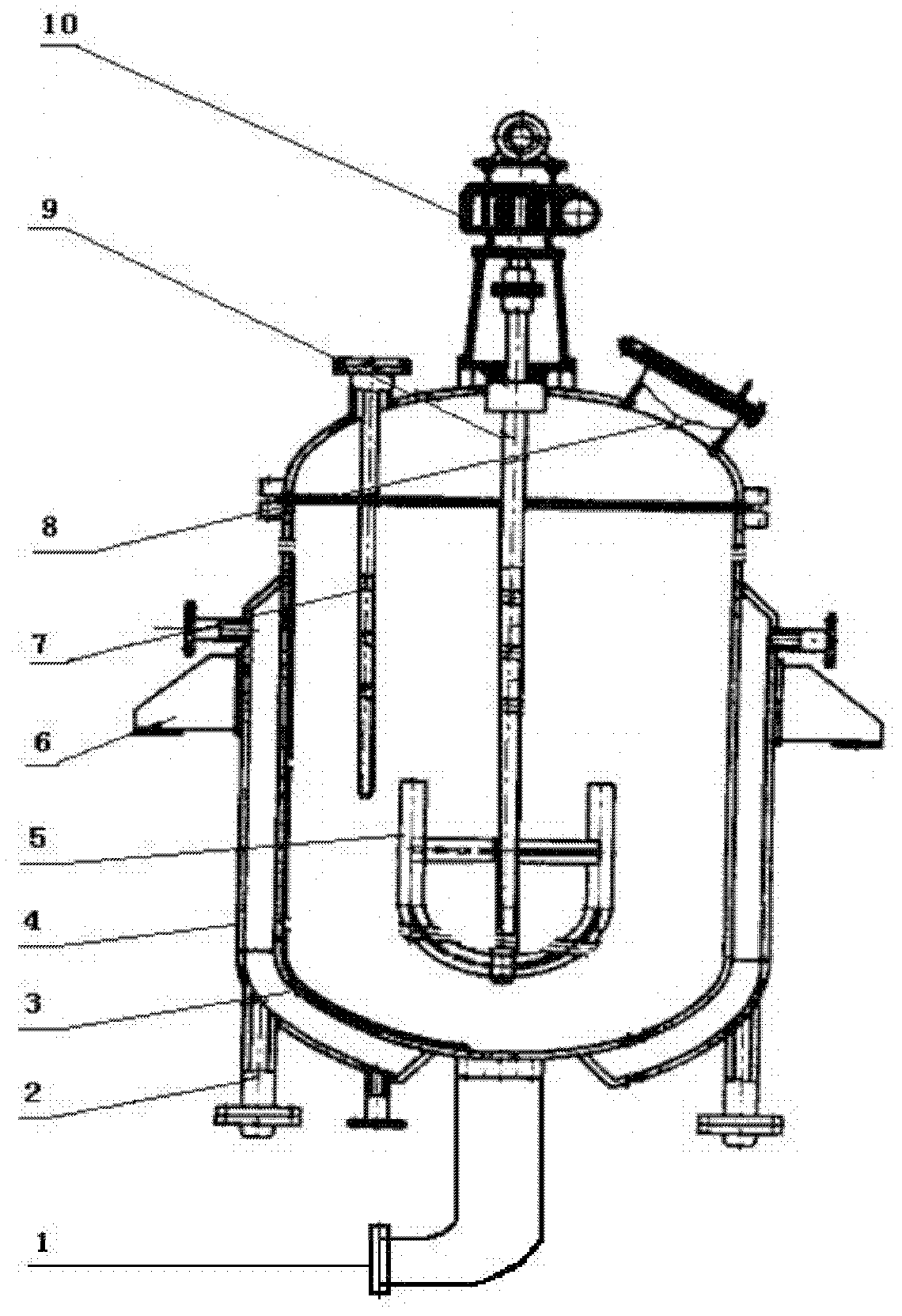

[0028] 1. Add 100kg of water at 30°C to figure 1 In the mixing kettle shown.

[0029] 2. Add 42kg of zinc oxide to the mixing kettle and stir for 15 minutes.

[0030] 3. Add 6kg of silicone oil into the mixing kettle and stir for 30 minutes.

[0031] 4. Add 5kg of sodium carbonate to 5kg of water to dissolve, then slowly add to the mixing kettle, keep the mixing kettle at 50°C, and discharge after mixing for 2 hours.

[0032] 5. Dry at 110°C for 4 hours.

[0033] 6. Grind the dried material and pass through a 400-mesh sieve.

Embodiment 2

[0035] 1. Add 200kg of water at 30°C to figure 1 In the mixing kettle shown.

[0036] 2. Add 170kg of magnesium oxide and zinc oxide to the mixing kettle, and stir for 15 minutes.

[0037] 3. Add 24kg of silicone oil-acetone to the mixing kettle and stir for 30 minutes.

[0038] 4. Add 12Kg of sodium carbonate and 8Kg of sodium silicate to 10kg of water to dissolve, then slowly add to the mixing kettle, keep the mixing kettle at 70°C, and discharge after mixing for 1.5 hours.

[0039] 5. Dry at 130°C for 4 hours.

[0040] 6. Grind the dried material and pass through a 400-mesh sieve.

Embodiment 3

[0042] 1. Add 150kg of water at 30°C to figure 1 In the mixing kettle shown.

[0043] 2. Add 170kg of zinc carbonate to the mixing kettle and stir for 15 minutes.

[0044] 3. Add 24kg of silicone oil-acetone to the mixing kettle and stir for 30 minutes.

[0045] 4. After dissolving 10Kg of potassium hydroxide and 8Kg of sodium silicate in 10kg of water, slowly add them into the mixing tank, keep the mixing tank at 70°C, and discharge after mixing for 1.5 hours.

[0046] 5. Dry at 130°C for 4 hours.

[0047] 6. Grind the dried material and pass through a 400-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com