Equipment removal rate monitoring method

A technology of removal rate and equipment, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of prolonged wafer cycle time, high cost and time consumption, and difficulty in recycling and reuse of wafers, so as to increase detection efficiency, improve work efficiency, and prolong the effect of normal production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a single layer to be etched, and the etching stops at the stop layer.

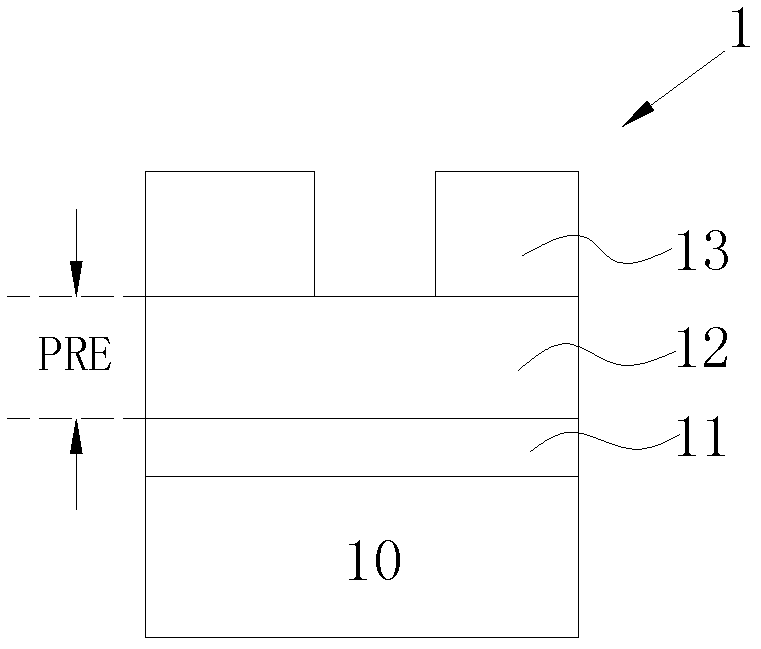

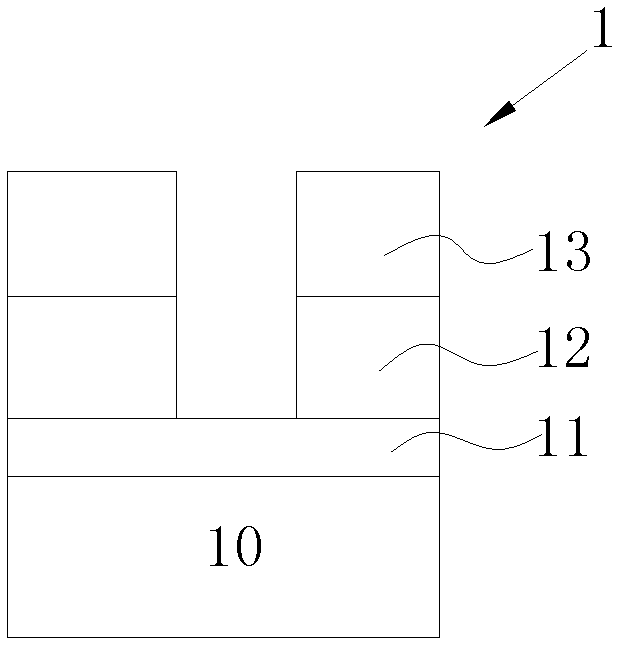

[0037] see Figure 1aThe shown production wafer 1 includes a substrate 10, a stop layer 11 formed on the substrate 10, a layer to be etched 12 formed on the stop layer 11, and a patterned mask layer formed on the layer to be etched 12 13. Wherein, the substrate 10 may be a silicon substrate, a germanium substrate, silicon-on-insulator, or other semiconductor substrates. Described stop layer 11 can be oxide, nitride or oxynitride according to the needs of actual production, certainly, when substrate 10 itself and layer 12 to be etched have large etch selective ratio, also can be the substrate 10. surface. The layer to be etched 12 may be oxide, nitride, oxynitride, polysilicon, etc., and has a large etching selectivity ratio with the stop layer 11, for example, an etching selectivity ratio greater than 10. The patterned mask layer 13 can be a photoresist or other hard mask, and can b...

Embodiment 2

[0039] Embodiment 2: single layer to be etched, etching does not stop at the stop layer.

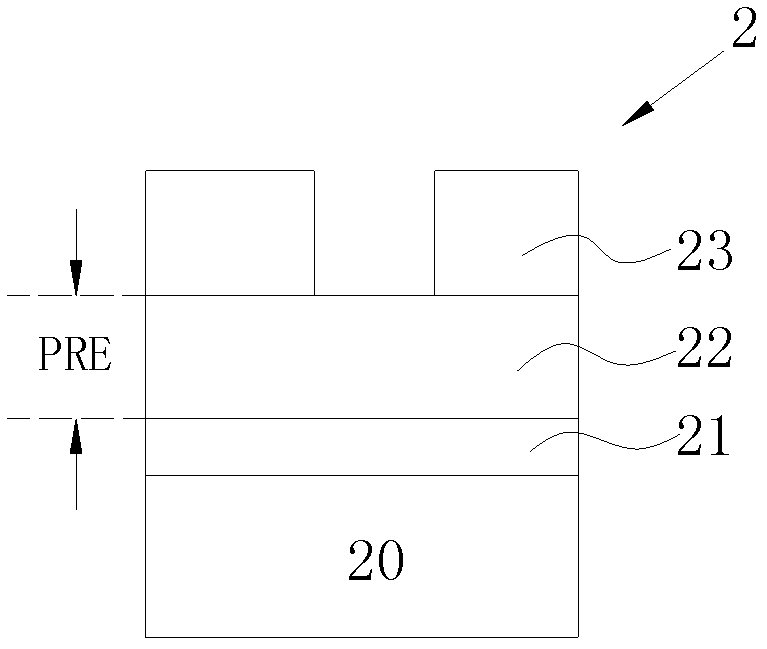

[0040] see Figure 2a Production wafer 2 is shown, with Figure 1a Similarly, it includes a substrate 20 , a stop layer 21 formed on the substrate 20 , a to-be-etched layer 22 formed on the stop layer 21 , and a patterned mask layer 23 formed on the to-be-etched layer 22 .

[0041] Before etching, first measure the thickness PRE of the layer 22 to be etched; then use (dry or wet) etching equipment to etch the layer 22 to be etched exposed by the patterned mask layer 23 in the production wafer 2, and only part of the thickness is to be etched. The etching layer 22 is etched, and the etching stops at the layer 22 to be etched itself, see Figure 2b , while using Advanced Process Control (Advanced Process Control) equipment to monitor the etching process and obtain the time T of the etching process EPD . Measure the remaining thickness POS of the layer to be etched 22 exposed at this tim...

Embodiment 3

[0042] Embodiment 3: Multi-layer composite layer to be etched, etching stops at the stop layer.

[0043] see Figure 3a Production wafer 3 shown, with Figure 1a Similar includes the substrate 30, the stop layer 31 formed on the substrate 30, the to-be-etched layer formed on the stop layer 31 by composite superposition of two or more single layers 321, 322...32n, forming A patterned mask layer 33 on the layer to be etched 321 .

[0044] Before etching, first measure the thickness PRE of each single layer 321, 322...32n in the layer to be etched 1 、PRE 2 ......PRE n ; Then use dry etching equipment to etch each single layer 321, 322 ... 32n exposed by the patterned mask layer 33 in the production wafer 3 in sequence, and at the same time use end point detection equipment to monitor the etching process, And make the etching process of the layer to be etched stop on the stop layer 31, see Figure 3b . The etching time T of each single layer 321, 322...32n is collected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com